Super high-rise roof curtain wall installing system and construction method thereof

A technology of installation system and construction method, applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc., can solve the problems of complex curtain wall construction and low efficiency, achieve green construction construction benefits, and avoid multiple disassembly and assembly. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

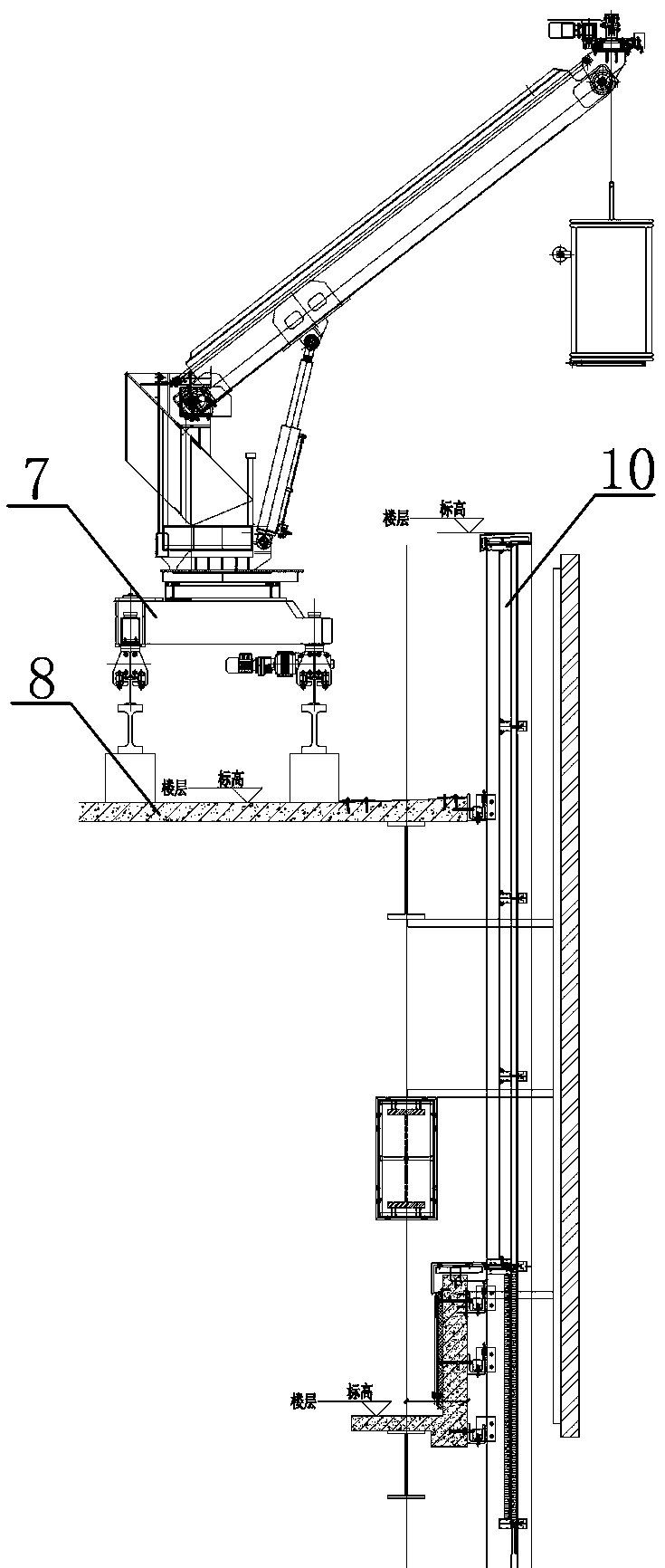

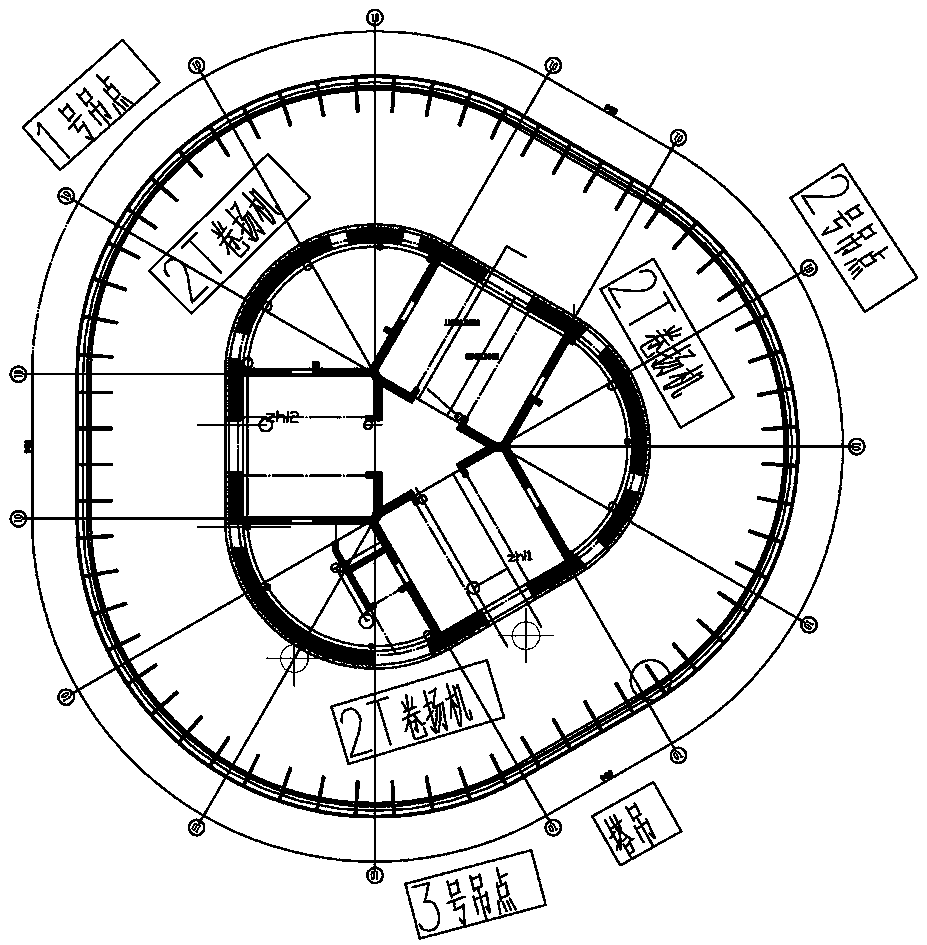

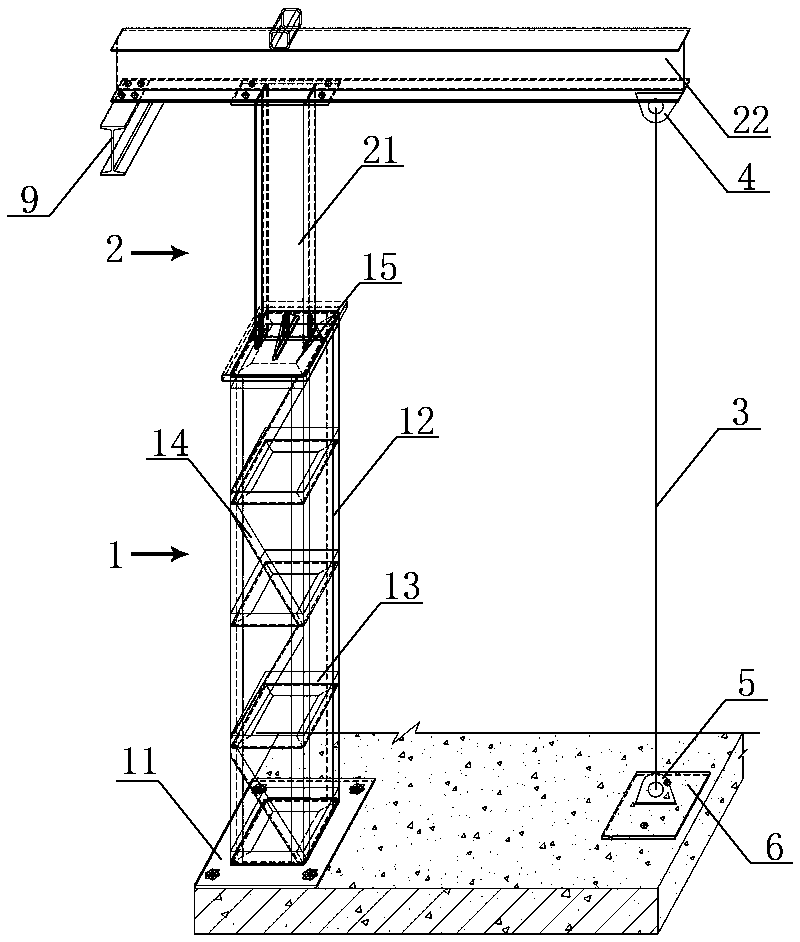

[0034] Examples see figure 1 As shown, in this example, the height of the existing window cleaning machine platform is 252.2m, while the maximum height of the curtain wall is 254.4m, and the cantilever height of the curtain wall is 2.2m; There is a lot of space; the outside of the curtain wall is designed with an external logo. Therefore, the installation of the curtain wall faces the following problems: 1. The height of the curtain wall exceeds the main structure by 2.2m, which exceeds the hoisting requirements of existing equipment; The construction space is small; 3. There are trademark logos and other existing structures on the outside of the lower curtain wall, and the construction conditions are complicated.

[0035] In order to solve the above problems, the present invention adds a curtain wall installation system on the basis of the traditional circular track, uses the support frame as a space heightening, and eliminates the influence of insufficient hoisting height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com