Circular tube and circular cylinder positioning early head removal device

A technology for early dismantling of heads and round pipes, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc. Good safety and reliability, quick disassembly and assembly, firm connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

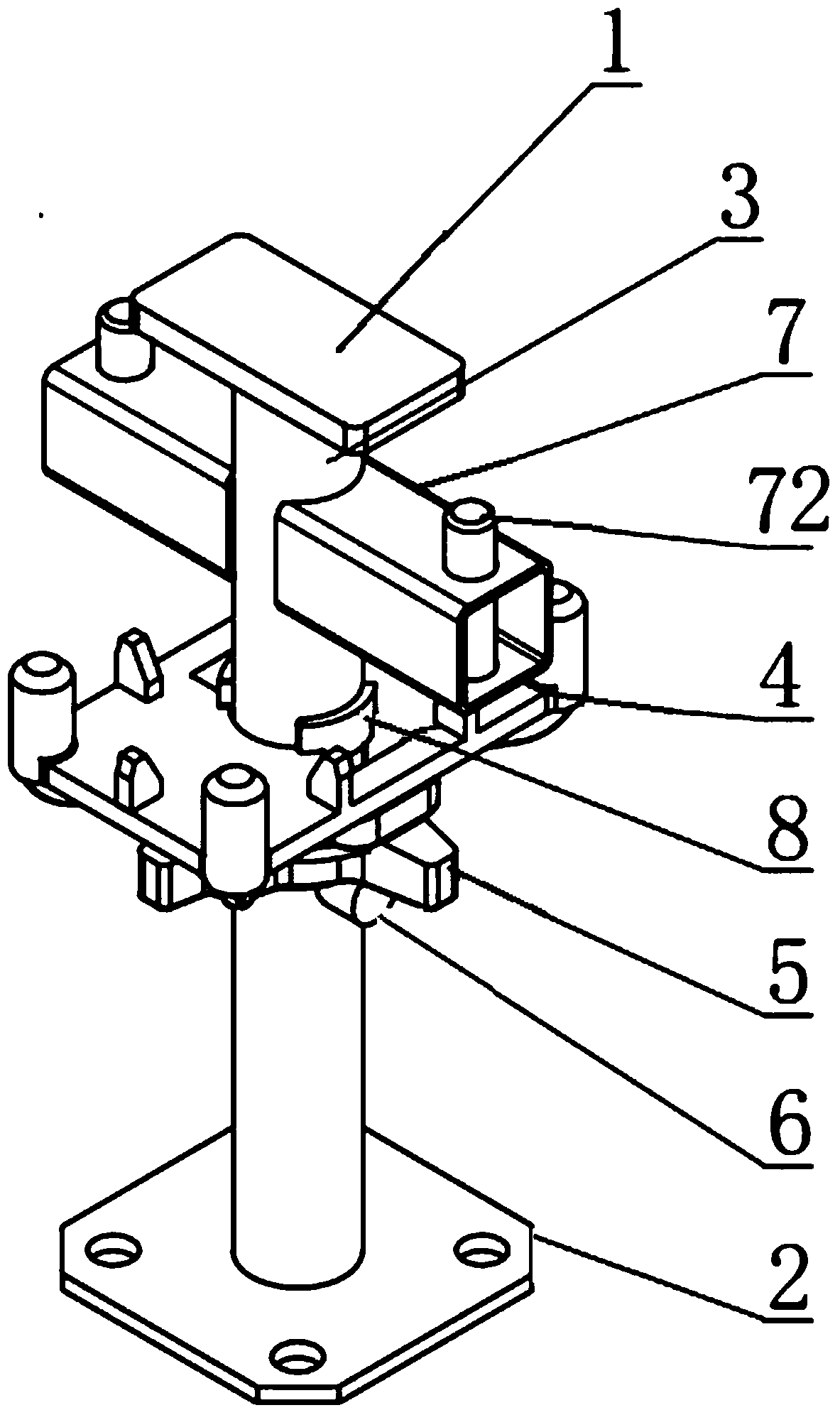

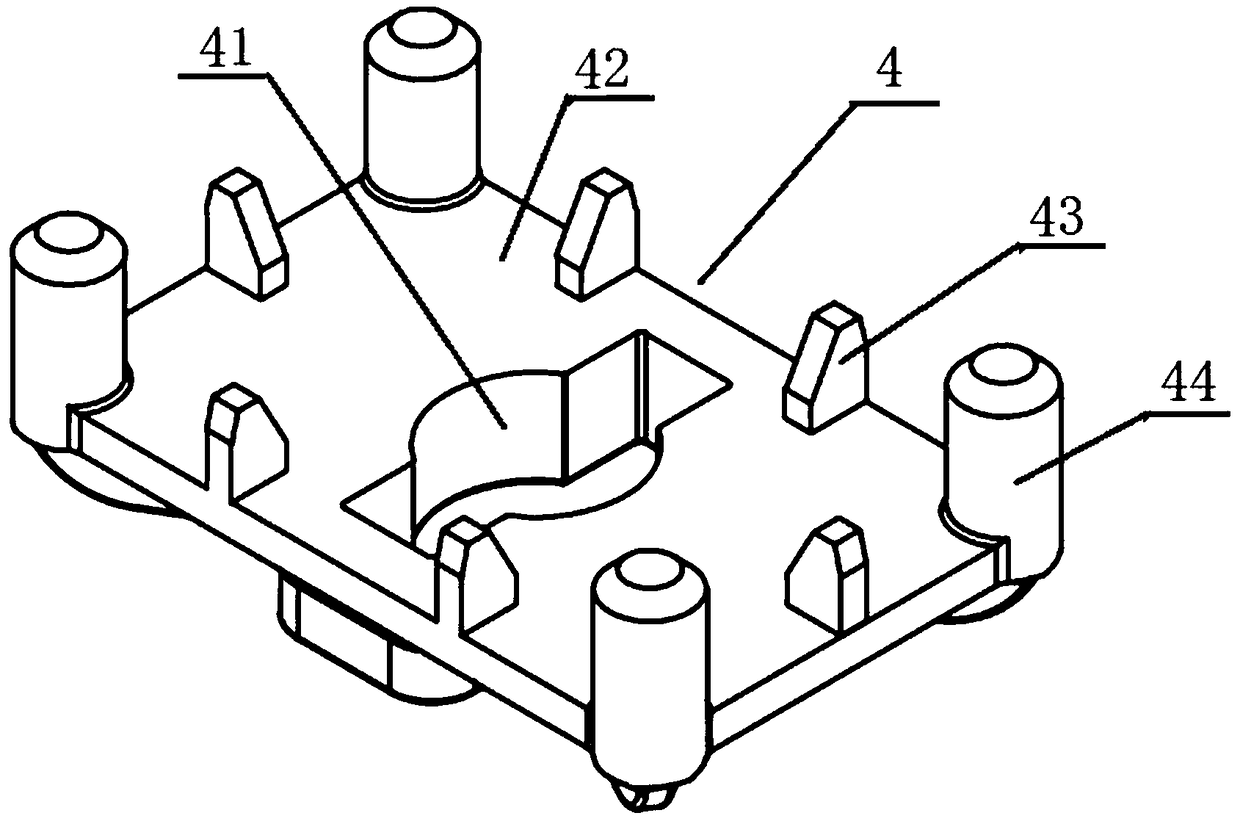

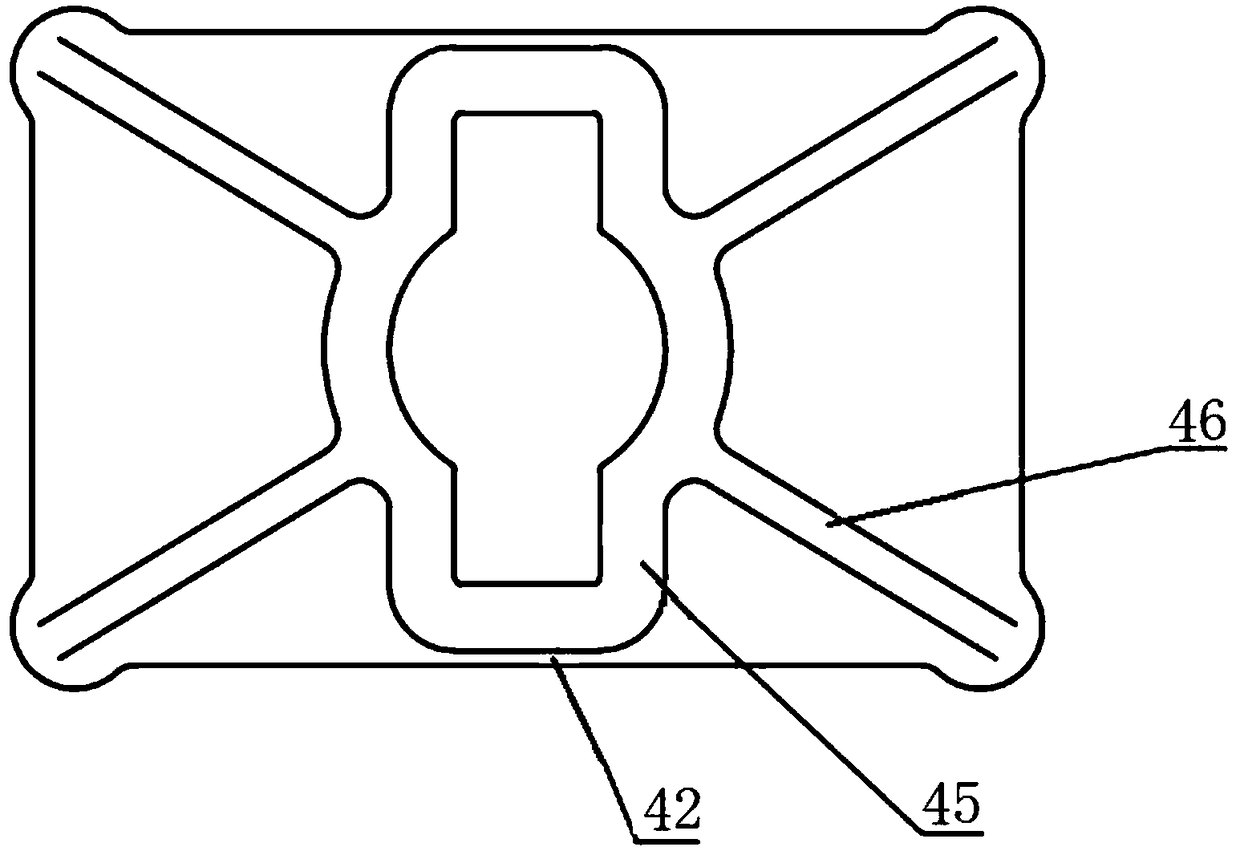

[0027] Such as Figure 1 to Figure 5 Shown is the first embodiment of the round tube cylinder positioning early dismantling device of the present invention, including a top plate 1 and a bottom plate 2 for connecting external parts, a round tube 3 is vertically connected between the bottom plate 2 and the top plate 1; the round tube 3 The upper movable sleeve is provided with a limit bracket 4 for supporting the external pendant and a locking piece 5 with self-locking function. , The limit bracket 4 and the middle part of the locking member 5 are respectively provided with a first slot 41 and a second slot 51 capable of accommodating the passage of the bearing pin 6 , and the bearing pin 6 is penetrated on the round pipe 3 . A tubular structure 7 is provided between the top plate 1 and the limiting bracket 4, and a connecting portion that cooperates with the external hanger is formed between the tubular structure 7 and the limiting bracket 4, and the external hanger is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com