Regenerated heat protection self-adaption control method and device for diesel engine DPF (diesel particulate filter)

A self-adaptive control and DPF technology, which can be applied to the electronic control of mufflers, exhaust devices, and exhaust treatment devices, etc. It can solve the problems of long DPF regeneration time and increase the risk of DPF regeneration and burning, and achieve optimal design. effect of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

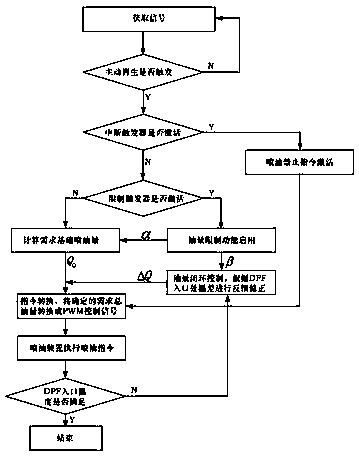

[0021] Specific embodiment one, see figure 2 , a diesel engine DPF regeneration heat protection adaptive control method is used to solve the problem that the DPF internal carrier is not burned during the regeneration process, comprising the following steps:

[0022] Step 1: Obtain the exhaust gas mass flow signal, the differential pressure signal across the DPF, the DOC inlet temperature signal, the DPF inlet temperature signal, and the DPF outlet temperature signal.

[0023] Step 2: Identify the capture amount information of particles in the DPF, set the target temperature of the DPF inlet during regeneration, and determine whether the active regeneration function of the DPF is enabled; if the active regeneration function is enabled, perform step 3; if the active regeneration function is not enabled, return to step two.

[0024] Step 3. Determine whether the interrupt trigger condition is met. If the interrupt trigger condition is met, issue a fuel injection prohibition com...

specific Embodiment 2

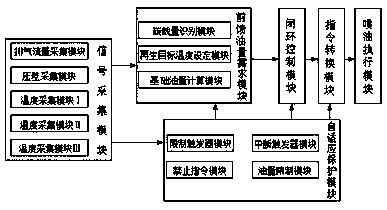

[0036] see figure 1 , an adaptive control device for diesel engine DPF regeneration heat protection, including a signal acquisition module, a feed-forward fuel quantity demand module, a closed-loop control module, a command conversion module, a fuel injection execution module and an adaptive protection module.

[0037] The signal acquisition module is used to acquire the exhaust gas mass flow signal, the differential pressure signal across the DPF, the DOC inlet temperature signal, the DPF inlet temperature signal and the DPF outlet temperature signal.

[0038] The feed-forward oil quantity demand module is used to identify the trapping quantity information of particles in the DPF, set the target temperature of the DPF inlet during regeneration, judge whether the active regeneration function of the DPF is turned on, and calculate and output the required base oil quantity information.

[0039] The self-adaptive protection module is used to judge whether the interrupt trigger co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com