Insulating cover

A heat shield and outer cover technology, which is applied in the direction of noise reduction devices, engine components, machines/engines, etc., can solve the problems of large unit weight of heat shields, adverse effects of automobile energy consumption, and increased use costs, so as to achieve light weight and reduce The difficulty of processing and manufacturing, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

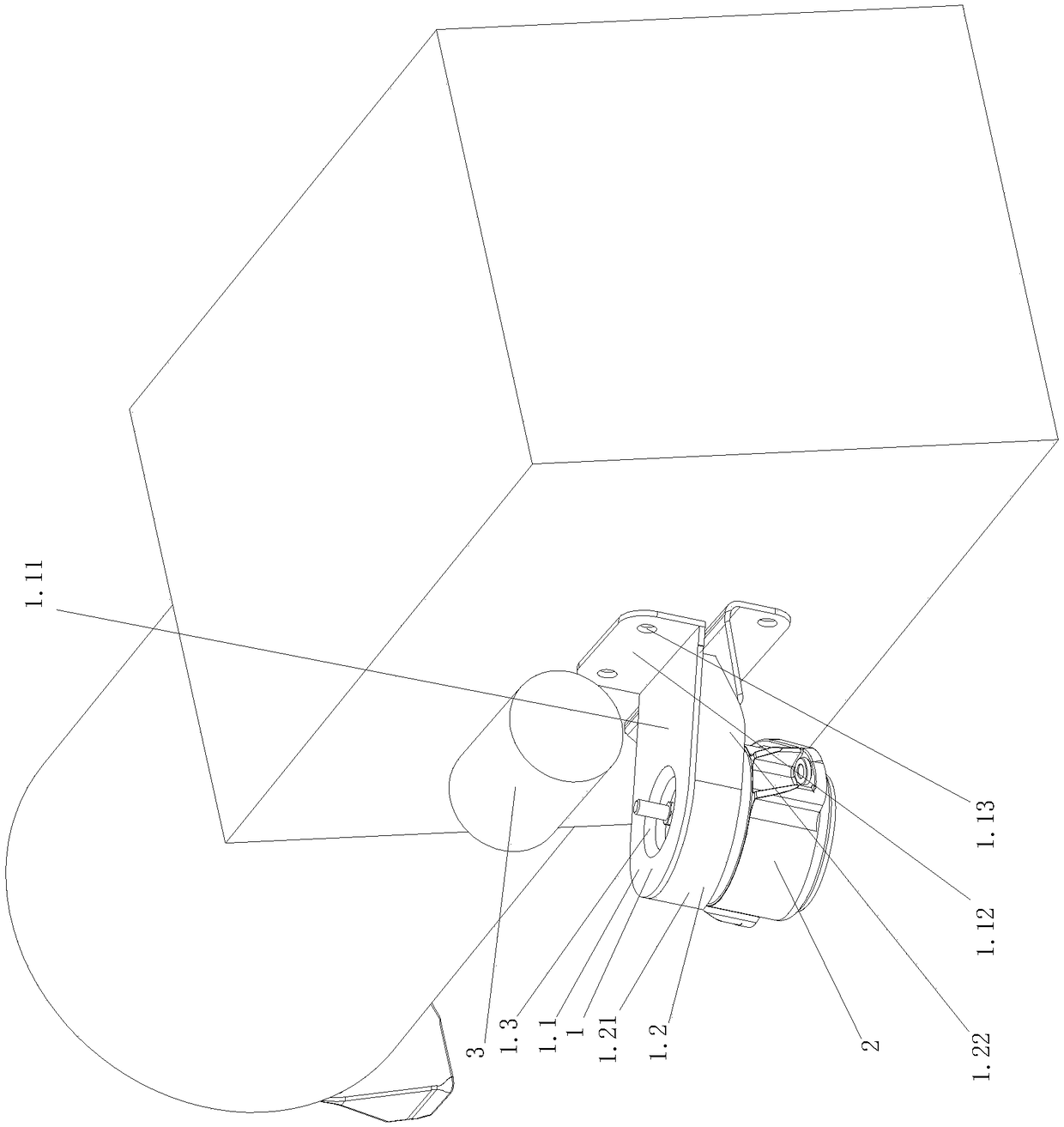

[0014] Such as figure 1 As shown, the heat shield 1 is arranged between the vertical power assembly 2 and the exhaust pipe 3 . The heat shield 1 is an antirust aluminum plate heat shield, comprising a heat shield main body 1.1, a heat shield outer cover 1.2 and a heat shield inner cover 1.3. The main body 1.1 of the heat shield includes the connecting part 1.11 of the outer and inner cover and the fixing part 1.12 of the heat shield. One end of the fixing part 1.12 is a semicircle, and the middle part of the connecting part 1.11 of the outer and inner cover is provided with a circular hole adapted to the inner cover 1.3 of the heat shield. The heat shield outer cover 1.2 includes an outer cover semi-cylinder 1.21 and two parallel outer cover side walls 1.22, the outer cover semi-cylinder 1.21 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com