A gas water seal rapid water replenishment and drainage cylinder on-line unclogging device

A drainage cylinder, gas water technology, applied in cleaning hollow objects, cleaning methods and utensils, gas/liquid distribution and storage, etc., can solve the problems of not eliminating the impact hazard of water seal, not timely replenishing water function, and low degree of automation, etc. Achieve the effect of facilitating large-scale promotion and application, low cost, and ensuring dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

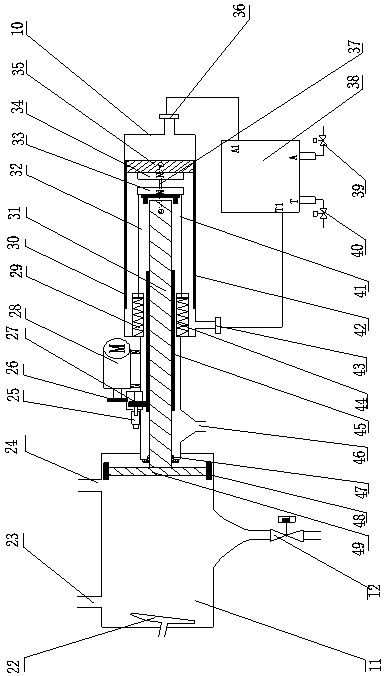

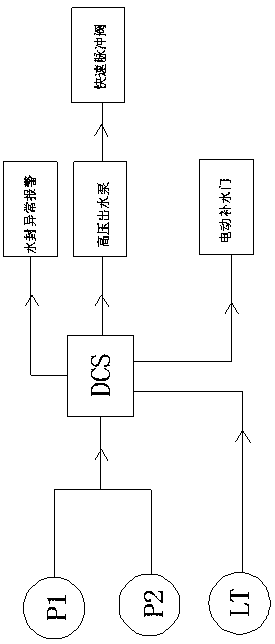

[0028] Embodiment 1: see Figure 1-Figure 2 , a gas water seal rapid replenishment and drainage cylinder online blockage removal device, the online blockage removal device includes a high-coal U-shaped water seal 1, a magnetic replica water level gauge 2, a remote liquid level transmitter 3, and a water replenishment water inlet 4 , water supply Unicom pipe 5, overflow pipe 6, overflow valve 7, overflow observation port 8, pneumatic cleaning device 10, water seal drainage cylinder 11, electric control sewage valve 12, water seal descending communication valve 14, water seal pressure measuring point 20 and gas pressure measuring point 21, the high-coal U-shaped water-sealed pipe 1 is installed between the high-coal pipeline flow direction pipes, a magnetic replica water level gauge 2 is installed on one side of the U-shaped pipe, and a magnetic replica water level gauge 2 is added to the bottom of the magnetic replica water level gauge 2. Install remote liquid level gauge 3, ad...

Embodiment 2

[0029] Example 2: see Figure 1-Figure 2 , as an improvement of the present invention, the pneumatic cleaning device 10 is fixedly installed on one side of the drain cylinder 11, the cavity of the pneumatic cleaning device 10 contains a piston 35, and the second permanent magnet N-pole push head 34 is fixedly connected to the piston 35, Slide grooves 30, 42 are installed on each side of the upper and lower walls of the cleaning device cavity, and the piston 35 can move freely between the slide grooves.

[0030] Example, 3: see Figure 1-Figure 2 , as an improvement of the present invention, the online blockage removal device also includes a push rod 31, a worm 45, a telescopic rod 32, a first permanent magnet N-pole push head 33, a cleaning disc 49, a fixed connecting rod 37, a telescopic Mechanism 29, a push rod 31 is embedded in the cavity of the pneumatic cleaning device 10, and a section of worm 45 is installed in the middle of the push rod 31, wherein the push rod 31 and...

Embodiment 4

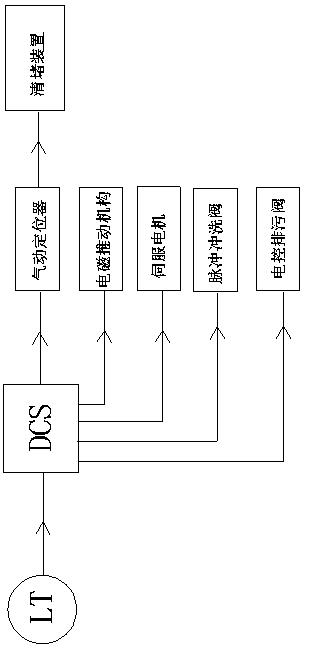

[0031] Embodiment 4: see Figure 1-Figure 2 , as an improvement of the present invention, the online blockage removal device also includes a servo motor 28, an intermediate gear 27, a servo motor gear 26, and an electromagnetic push mechanism 25, and a servo motor 28 is installed on the drain cylinder and the bracket of the pneumatic cleaning device. The motor 28 is fixedly installed on the bracket, wherein the intermediate gear 27 is installed between the servo motor gear 26 and the push rod and the worm 45, and the intermediate gear 27 engages tooth-to-teeth through the electromagnetic push mechanism 25, and the online block removal device also includes The pneumatic positioner 38 is installed on one side of the pneumatic cleaning device 10, the A1 output port of the pneumatic positioner is connected to the air source interface 36 of the cleaning device, and the T1 output port of the pneumatic positioner is connected to the air source interface 43 of the cleaning device Conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com