High-pressure manifold detection method

A detection method and technology of high-pressure manifolds, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of low fracturing construction efficiency, inability to quantitatively detect, puncture, etc., and reduce fracturing operations. The effect of high risk, high detection efficiency and high detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the embodiments of the present invention will be clearly and completely described below in combination with specific embodiments of the present invention.

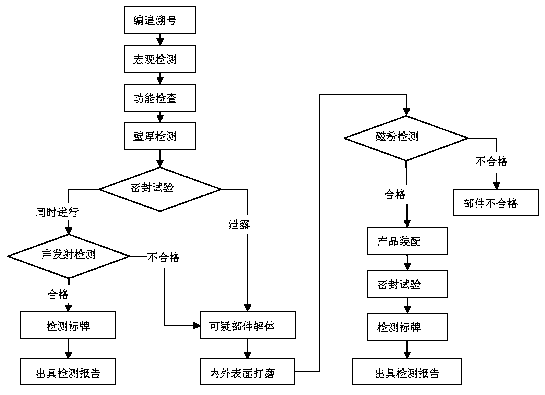

[0022] The high-pressure manifold detection and maintenance method of the present invention comprises the following process steps:

[0023] 1. Traceability number: compile a unique detection number for each piece of high-pressure manifold to be tested for traceability and management;

[0024] 2. Macroscopic inspection: inspect the appearance of high-pressure manifold components, check the inner and outer surfaces through visual inspection, endoscope or 5-10 times magnifying glass, and check whether there are defects such as deformation, cracks or obvious erosion and corrosion pits;

[0025] 3. Functional inspection: Check the function of high-pressure manifold components. Valve switches and swivel elbows should be flexible and light in rotation, and there must be no rust or rust.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com