Radiation Refrigeration Particle and Vapor Condensation Recovery Unit

A technology of radiation refrigeration and recovery device, used in refrigeration and liquefaction, steam/vapor condensers, refrigerators, etc., can solve the problems of adsorbent harmful to human body and the environment, consume large electric energy, and high requirements for adsorbent efficiency, and achieve condensation efficiency. good effect, promoting vapor condensation and good heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

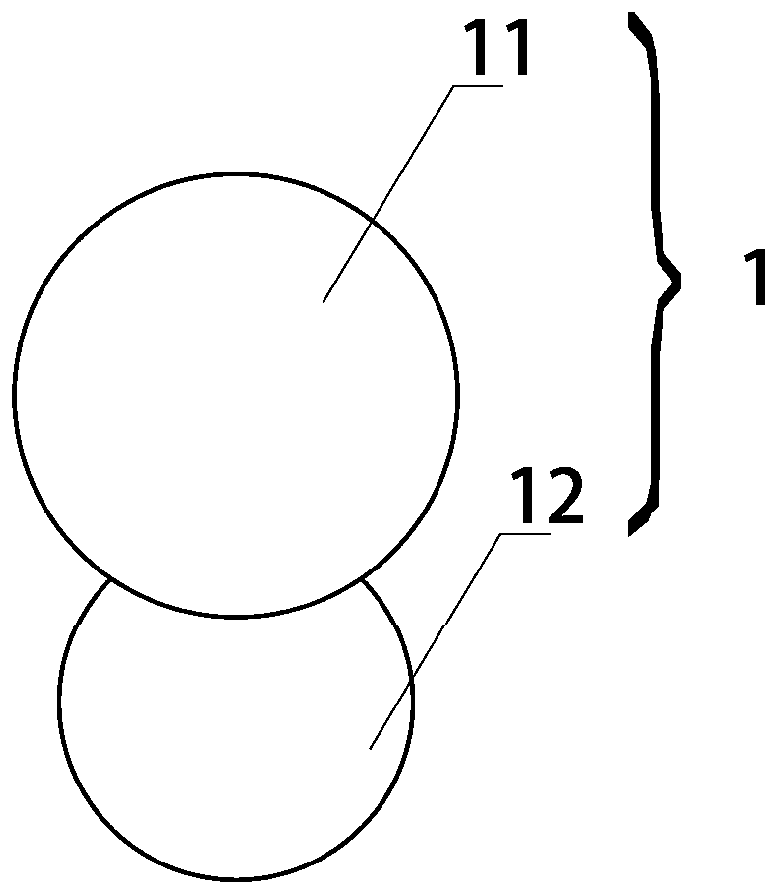

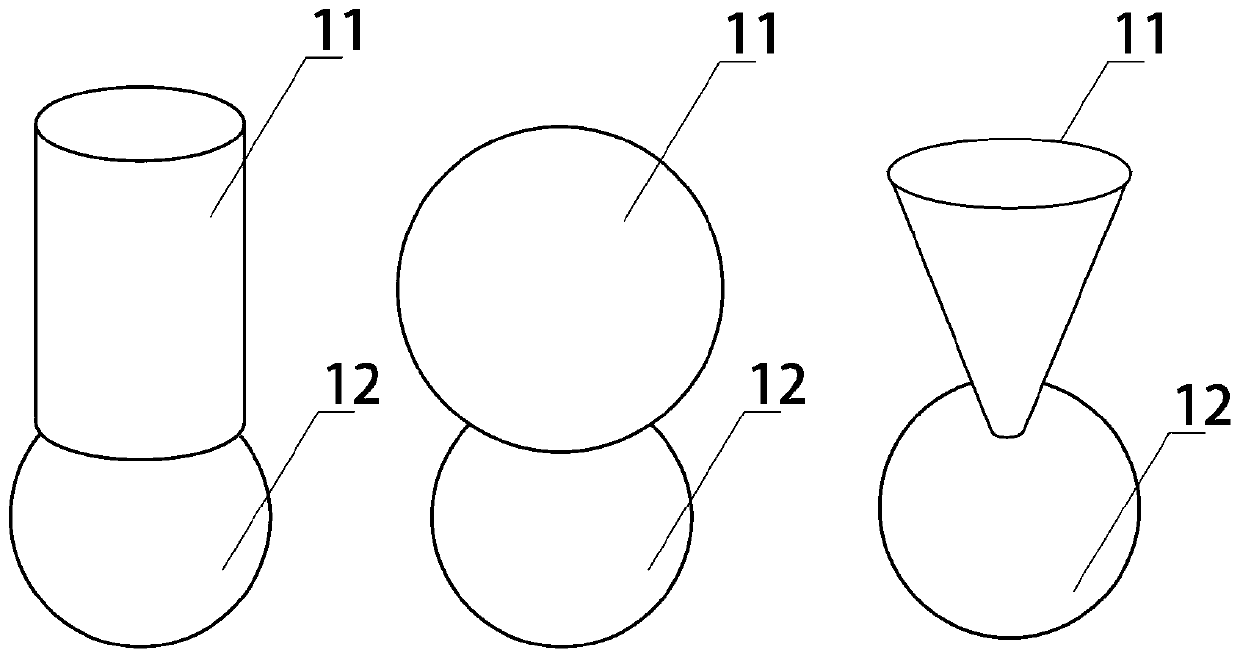

[0048] The first embodiment of the present invention provides a radiant cooling particle 1, see figure 1 As shown, it includes: condensate liquid 11, which is made of radiation refrigeration material;

[0049] The hydrophobic liquid 12 is connected with the condensate liquid 11 and is made of a liquid-repellent material;

[0050] When in use, the radiation cooling particles 1 are suspended in the medium under the blowing of the medium, and are used to condense the vapor in the medium.

[0051] Among them, the radiation cooling material is a material that can use infrared radiation to transfer heat from a heat source to a cold source in outer space through an atmospheric window of infrared radiation. Its refrigeration principle is similar to the natural refrigeration principle of the earth.

[0052]Those of ordinary skill in the art know that the energy of 200 petawatts that the earth absorbs from the sun every day is finally sent to the space near absolute zero in the form o...

Embodiment approach 2

[0062] The second embodiment of the present invention provides a radiation cooling particle 1 . The second embodiment is a further improvement of the first embodiment, the main improvement is that, in the second embodiment of the present invention, see image 3 As shown, the condensate 11 is in the shape of a film, a thin shell or a flat plate.

[0063] Among them, see Figure 3a As shown, the film shape refers to the shape of a flexible film formed with a curved surface, its thickness is thin, and its length and width are relatively large relative to the thickness, which may deform due to force.

[0064] see Figure 3b As shown, the shell shape refers to the shape of a rigid shell formed with a curved surface, which can be compared to the shape of a part of an egg shell.

[0065] see Figure 3c As shown, the flat plate shape refers to a shape in which both sides are flat, the thickness is smaller than the length and width, and the material is rigid.

[0066] Those of ord...

Embodiment approach 3

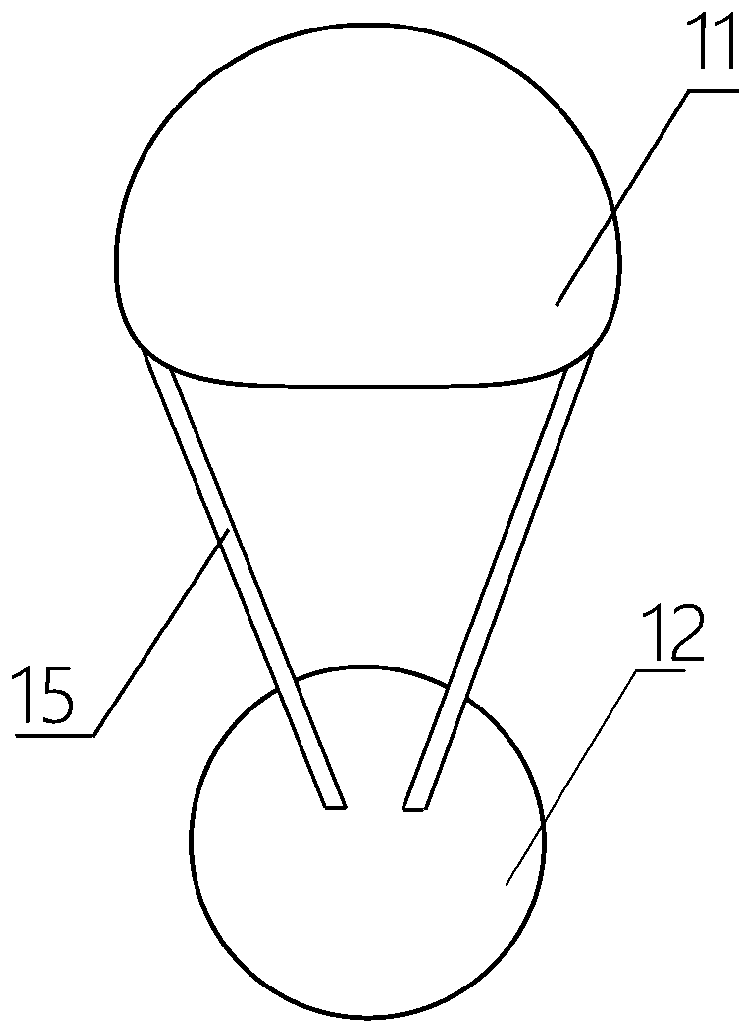

[0070] The third embodiment of the present invention provides a radiation cooling particle 1 . The third embodiment is a further improvement of the second embodiment, the main improvement is that, in the third embodiment of the present invention, see Figure 4 As shown, the hydrophobic liquid 12 is connected with the condensate liquid 11 through a thread 13 .

[0071] The condensate liquid 11 and the repellent liquid 12 are connected by wires 13 . Compared with the connection of the two by connecting rods 15 , the wires 13 are lighter and have almost no influence on the overall buoyancy of the radiative cooling particles 1 . Furthermore, under the action of gravity, the condensed liquid may carry the radiant cooling particles 1 and fall to the bottom of the vapor condensation chamber 2, and the liquid is detached from the surface of the radiative cooling particles 1 under the impact, and the wires 13 are less likely to be impacted. And detach from the radiation cooling partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com