Clamping method used in metal material mechanical property test

A technology of metal materials and mechanics, which is applied in the clamping field of metal material mechanical performance testing, can solve problems such as time-consuming and labor-intensive, lower clamping reliability, and lower detection efficiency, so as to avoid direct contact, improve efficiency, and improve clamping efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

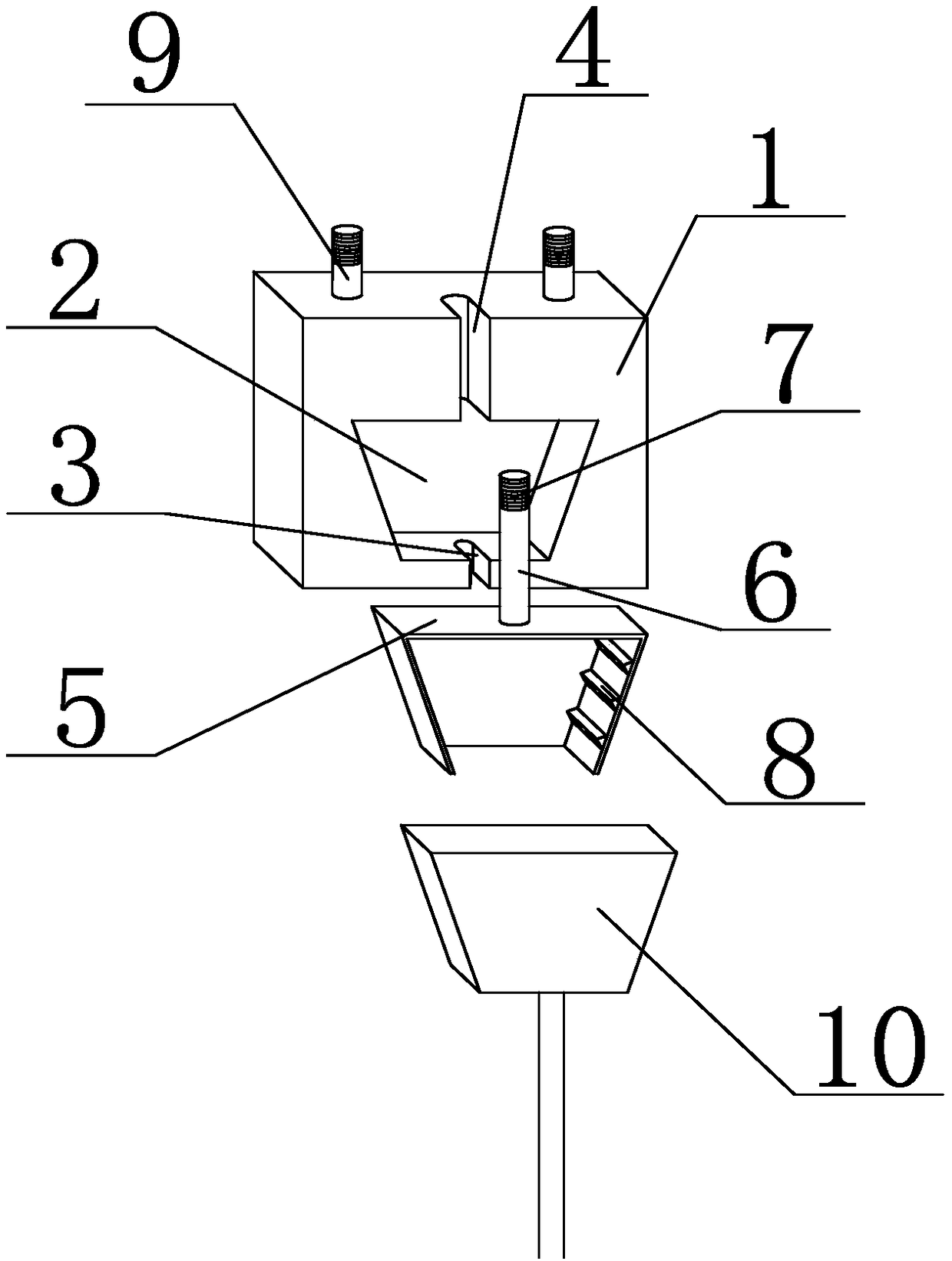

[0021] Such as figure 1 As shown, the present invention is used for the clamping method of metal material mechanical performance test, comprises the following steps: 1) material is processed into the bar-shaped sample to be tested that two ends have trapezoidal assembly segment; 2) sample to be tested is clamped in In the clamping device of the tensile testing machine; the clamping device comprises two clamping parts with the same structure and arranged symmetrically up and down, and the clamping parts include a fixed block 1, and an isosceles trapezoid The long side of the isosceles trapezoidal placement slot 2 is located above the short side, and the front side of the fixed block 1 on the short side of the placement slot 2 is provided with a vertical sample gap 3, the test The sample gap 3 runs through the bottom surface of the fixed block 1 and communicates with the placement groove 2. The front side of the fixed block 1 on the long side of the placement groove 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com