Reflective lens for ultrathin backlight module group

A backlight module and reflective technology, which is applied in the field of reflective lenses for ultra-thin backlight modules, can solve problems such as the inability to achieve mixed light heights, and achieve the effects of reduced thickness, large light output angle, and uniform light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The purpose of the present invention can be achieved through the following technical solutions:

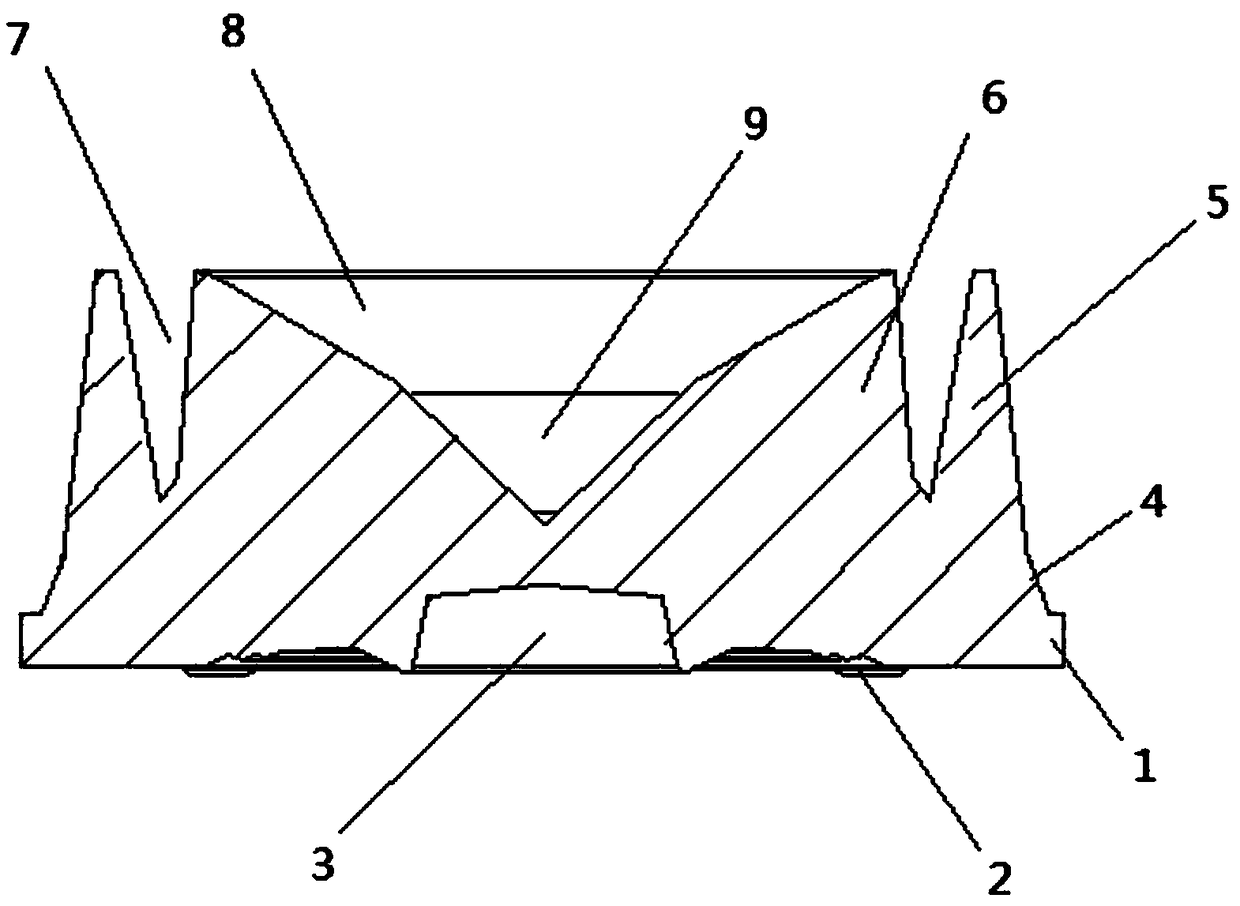

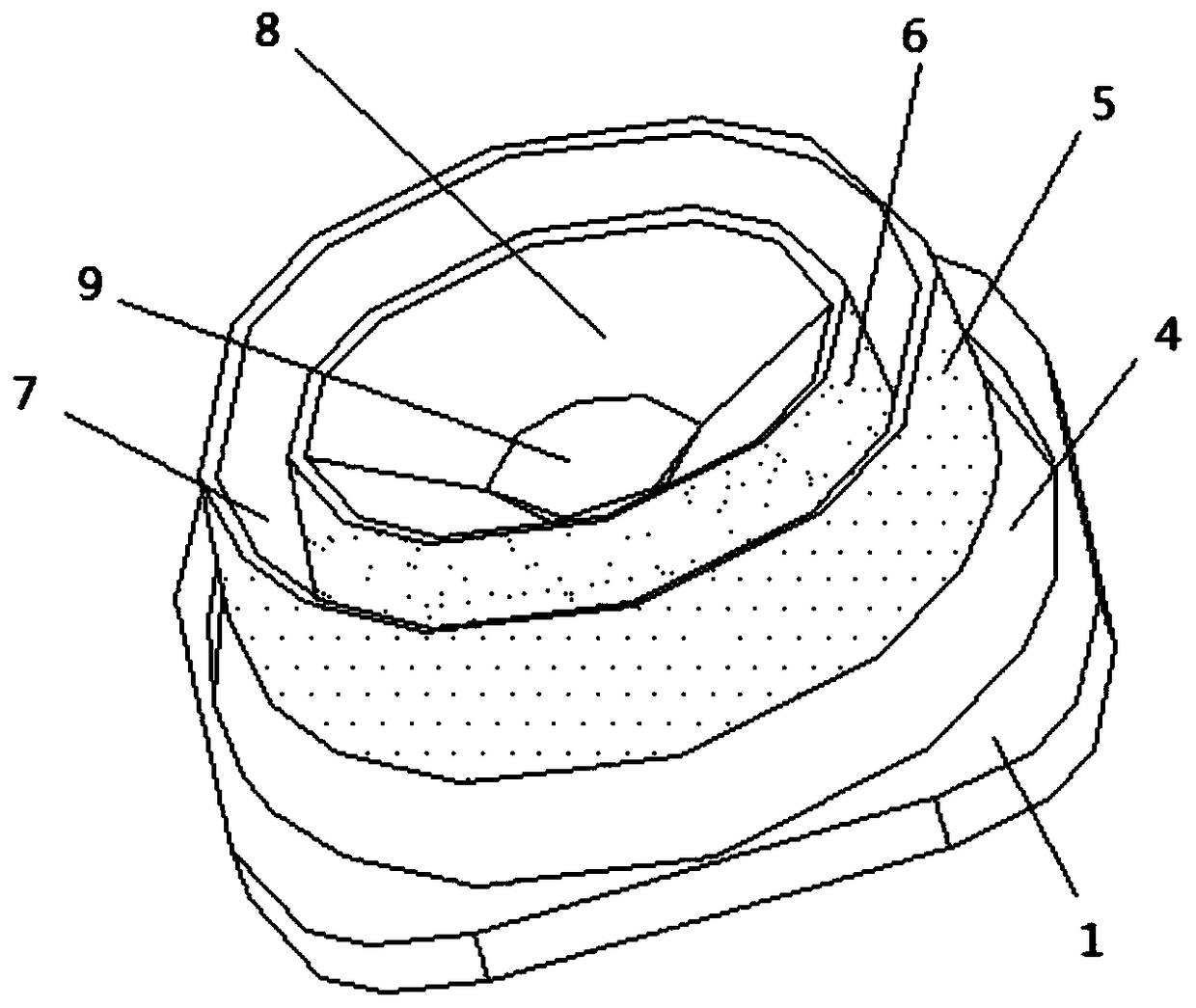

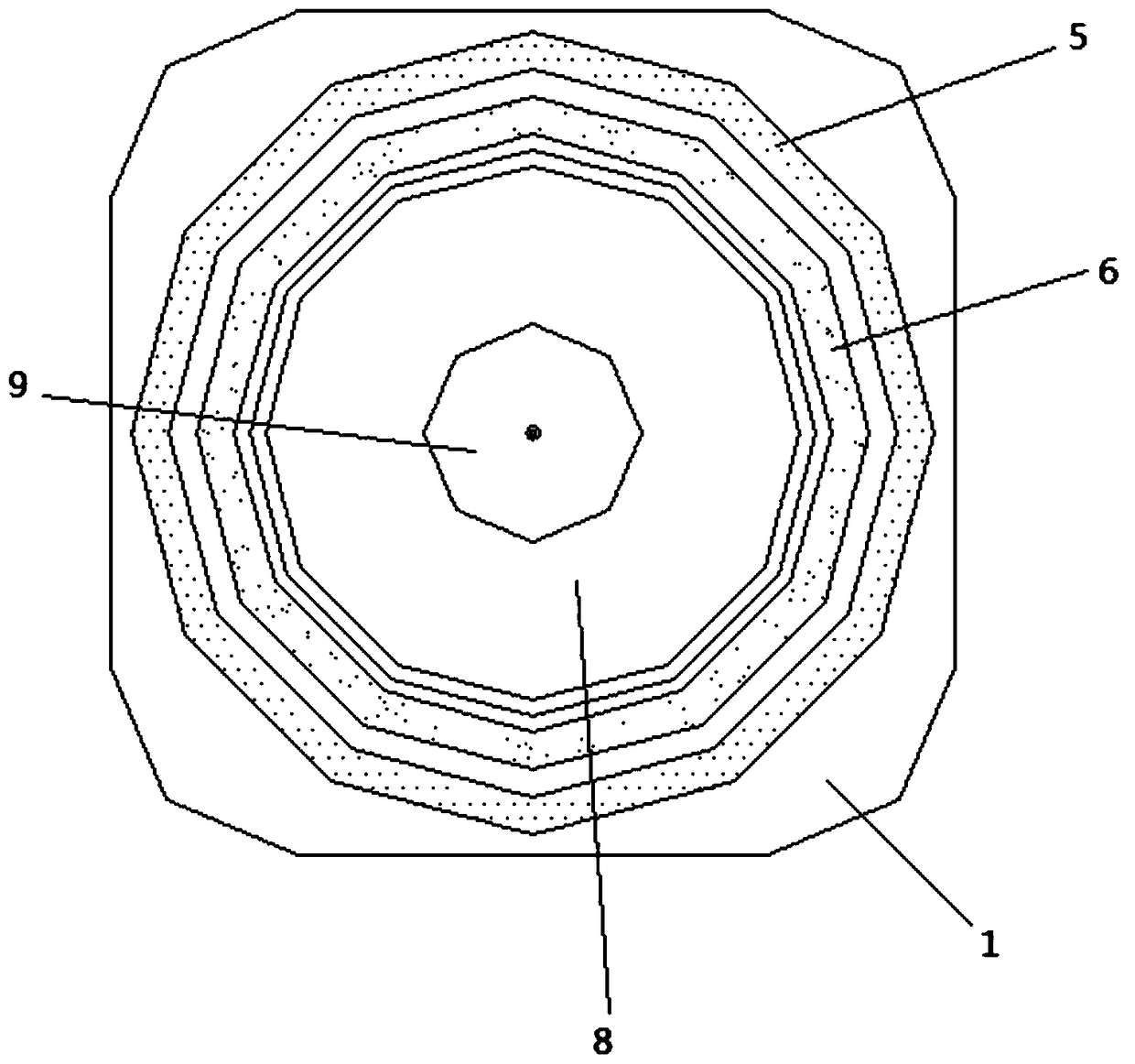

[0023] A reflective lens for an ultra-thin backlight module, see Figure 1-5 , including a carrier edge 1, a support column 2, a transmission cylinder 5, a central cylinder 6, a first astigmatism groove 8, and a second astigmatism groove 9;

[0024] The shape of the lens is a double-layer cylindrical structure; the lower surface of the lens is provided with a light source cavity 3, and the lower surface of the lens around the light source cavity 3 is provided with a support column 2; An astigmatism groove 8, a second astigmatism groove 9 is arranged below the first astigmatism groove 8; an astigmatism diffusion groove 7 is arranged on the upper surface of the lens outside the first astigmatism groove 8;

[0025] The first astigmatism groove 8, the second astigmatism groove 9, and the astigmatism diffusion groove 7 divide the upper surface of the lens into a central cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com