A Safe Braking Protection Structure for Azimuth Axis of Large-aperture Telescope

A technology for safe braking and protecting structures, applied in telescopes, instruments, optics, etc., can solve the problems of increased weight, large moment of inertia of azimuth shafting, inability to absorb kinetic energy, etc., and achieve the effect of enhancing reliability and remotely controlling structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

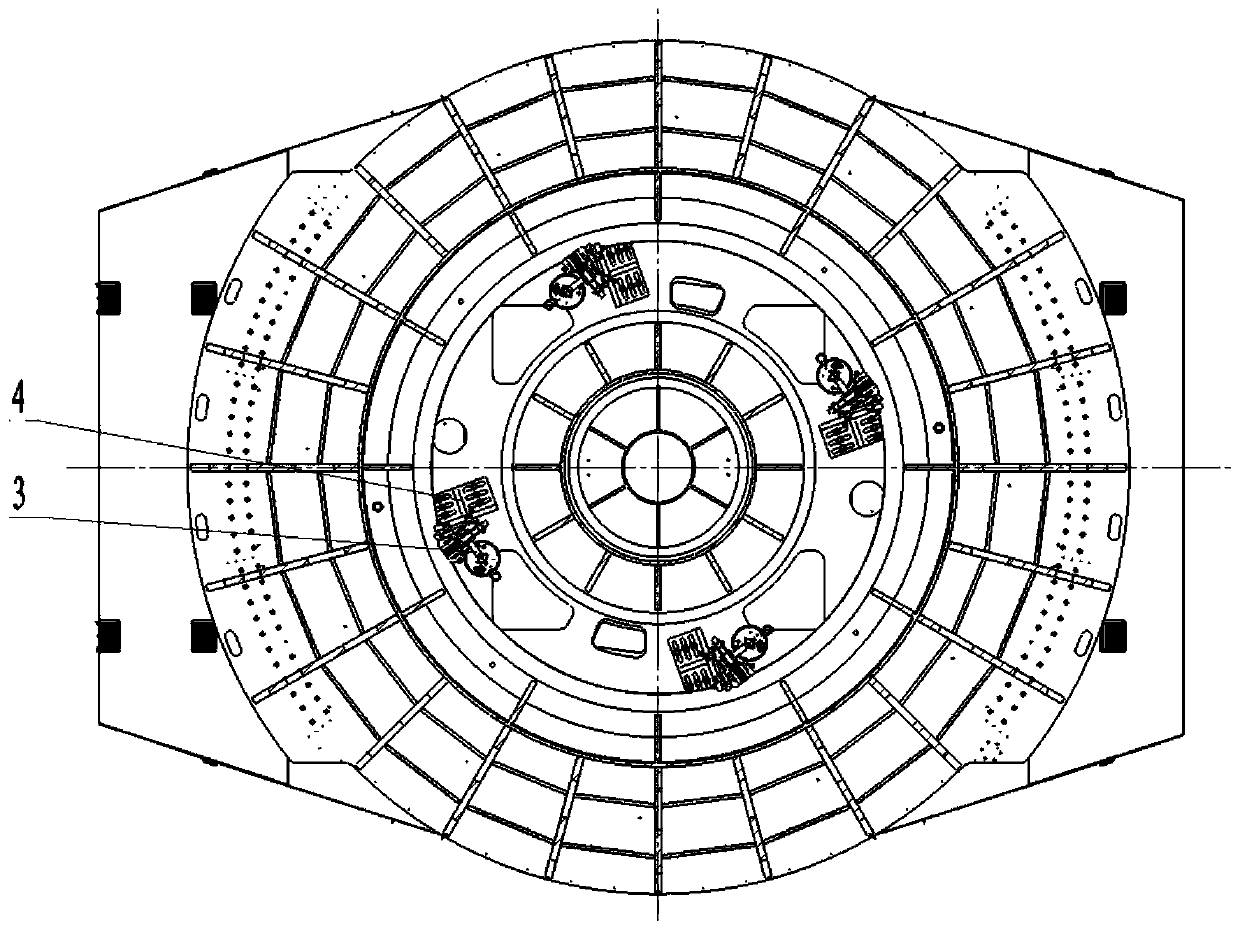

[0022] The invention discusses a safety braking protection structure for the azimuth axis of the large-diameter telescope. When the azimuth axis of the telescope needs to be braked, the disc brake is activated to clamp the brake ring on the base to complete the braking of the azimuth axis of the telescope.

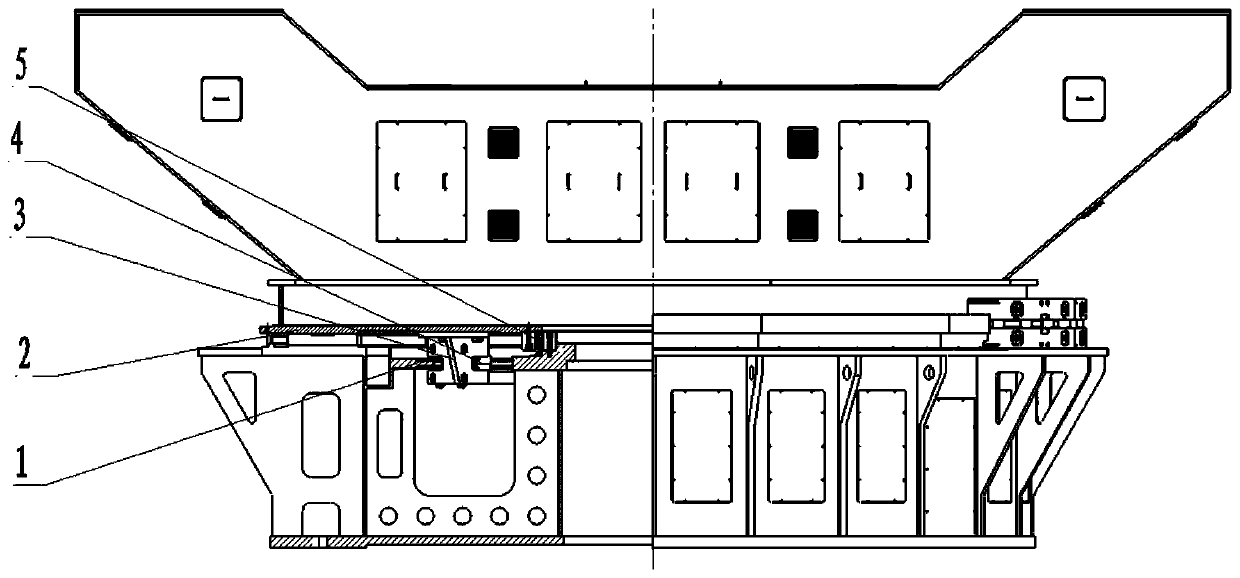

[0023] Such as figure 1 Shown is an assembly diagram illustration of the azimuth axis safety braking protection structure of the large-aperture telescope.

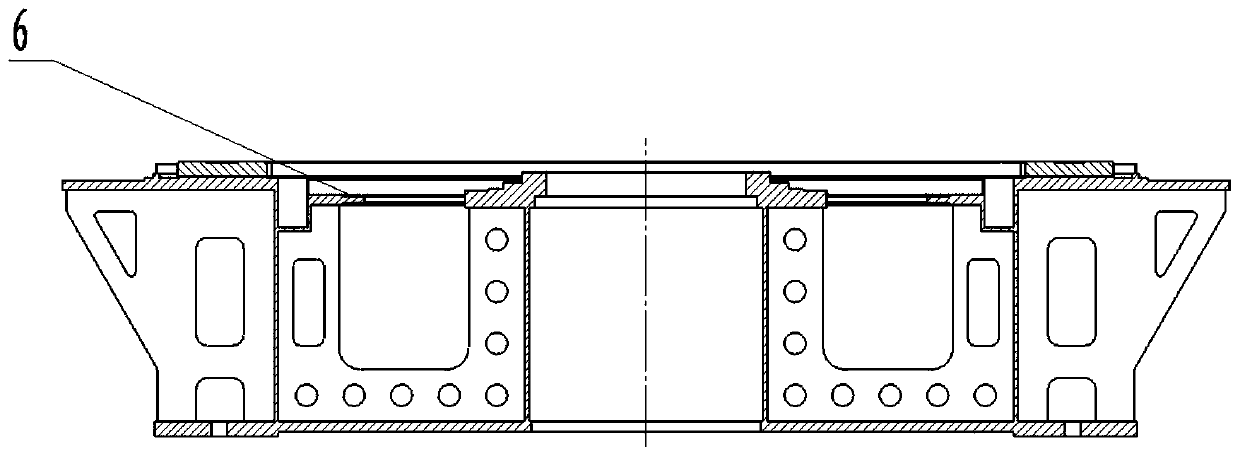

[0024] First of all, the interior space of the azimuth axis system of the telescope is relatively large, which can provide the installation position of the azimuth axis safety brake protection structure, and the staff can enter the interior of the azimuth axis system through the base 1, which is convenient for installation and maintenance. dynamic protection structure;

[0025] Second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com