A liquid crystal display panel

A liquid crystal display panel and display area technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of edge red lines, unable to completely block light leakage, yield decline, etc., to improve product yield and enhance ESD resistance. , the effect of eliminating the edge red line phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings. The direction term mentioned in the present invention, for example [upper], [next], [front], [after], [left], [right], [within], [outer], [side], etc., is only reference Additional pattern direction. Therefore, the direction term used is used to illustrate and understand the invention, not to limit the invention.

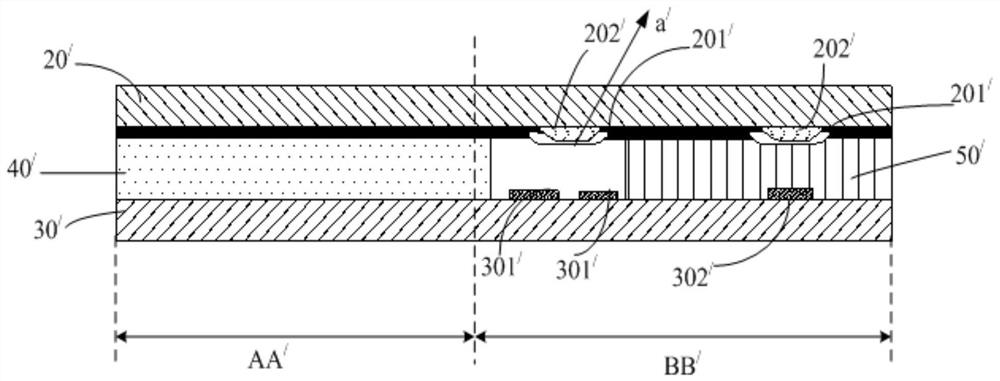

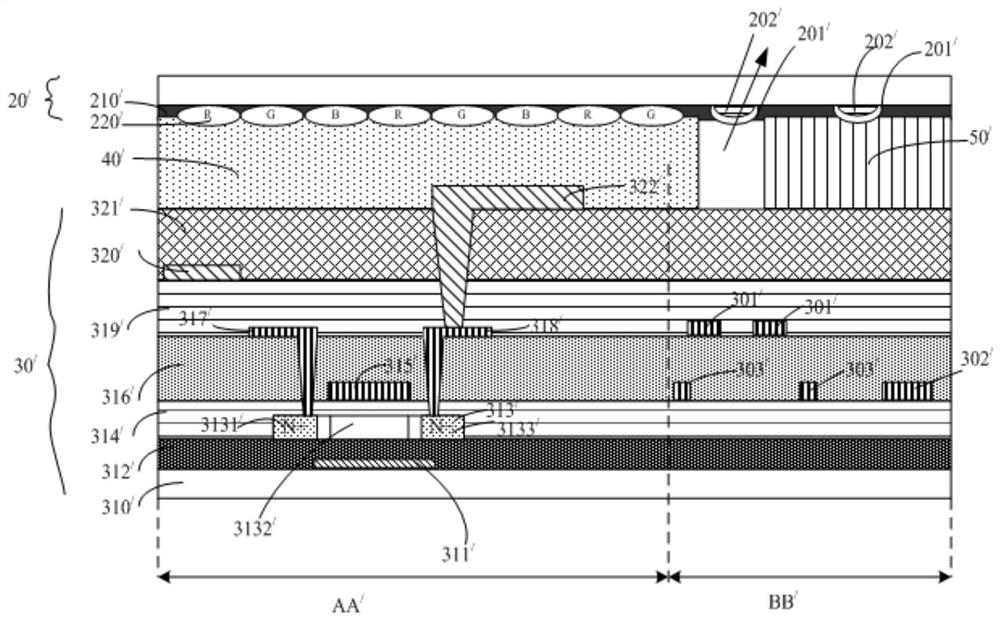

[0084] Such as Figure 4 As shown in the first embodiment of the present invention, a liquid crystal display panel provided, including an array substrate 30, a color film substrate 20, a liquid crystal layer 40, and a frame glue 50;

[0085] After the array substrate 30 is assembled from the color film substrate 20, the display area Aa formed on the array substrate 30 corresponds to the display area of the color film substrate 20, and the non-display area BB formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com