Sopc multi-axis linkage motion controller and control system based on fpga

A motion controller, multi-axis linkage technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of low speed regulation efficiency of motion control systems, prolonged upgrade cycles, and increased upgrade costs. Realize the effect of hardwareization and customization, speeding up the development cycle and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

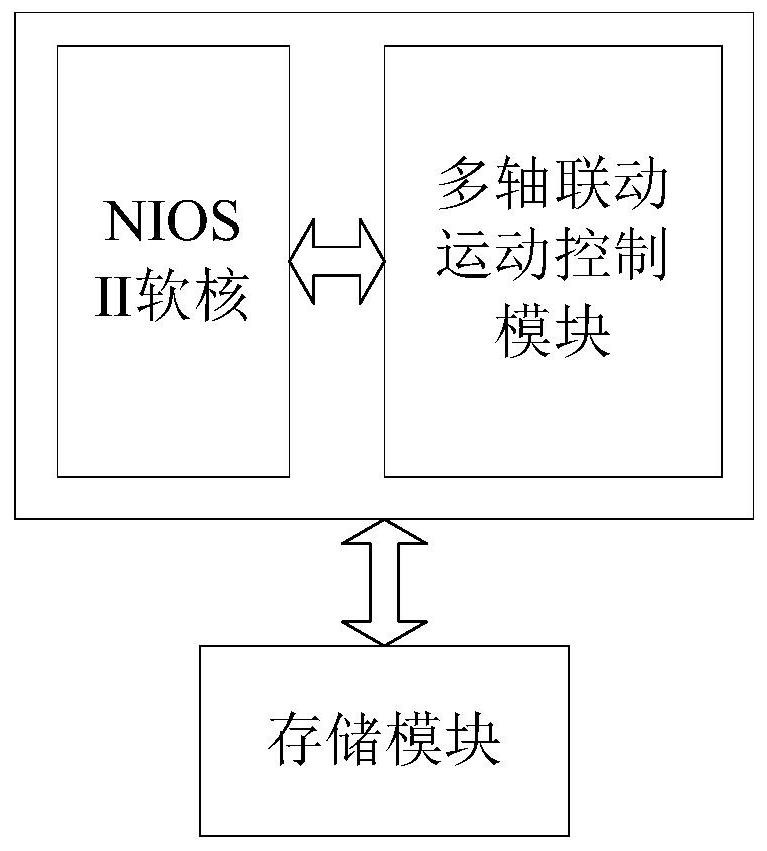

[0037] figure 1 It is a structural schematic diagram of Embodiment 1 of an FPGA-based SOPC multi-axis linkage motion controller of the present invention.

[0038] Such as figure 1 As shown, an FPGA-based SOPC multi-axis linkage motion controller of the present invention includes a storage module, a soft-core IP and a multi-axis linkage motion control module.

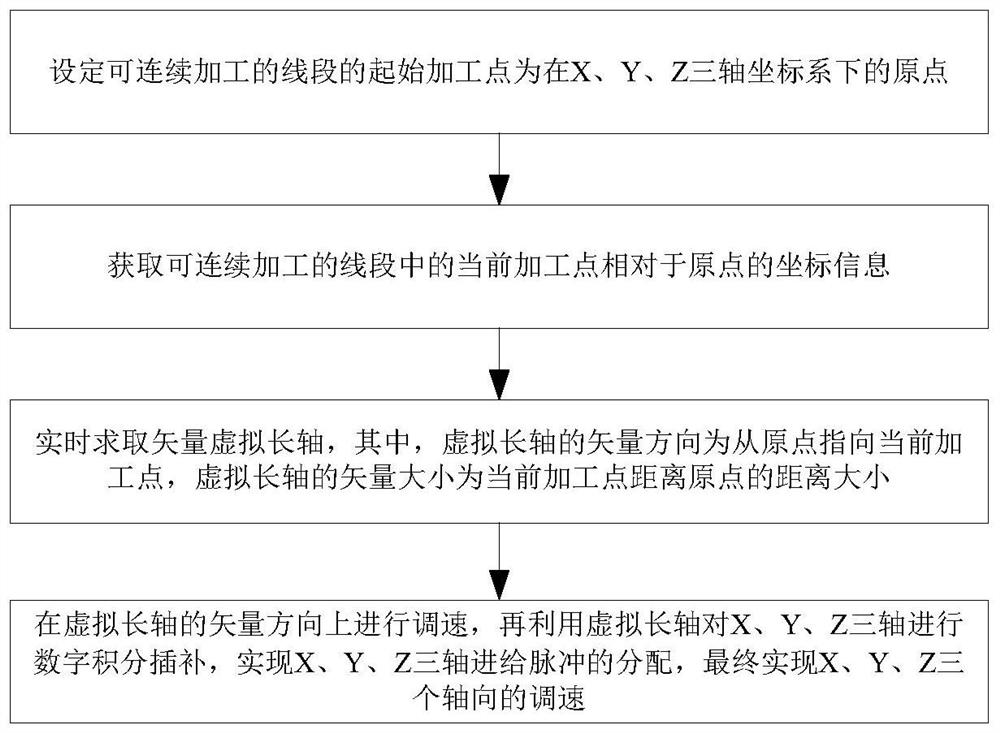

[0039] Such as figure 2 As shown, the multi-axis simultaneous motion control module is configured to execute the following procedures:

[0040] Set the starting processing point of the line segment that can be processed continuously as the origin in the X, Y, Z coordinate system;

[0041] Obtain the coordinate information of the current processing point relative to the origin in the line segment that can be processed continuously;

[0042] Calculate the virtual major axis of the vector in real time, wherein the vector direction of the virtual major axis is from the origin to the current processing point, and the vec...

Embodiment 2

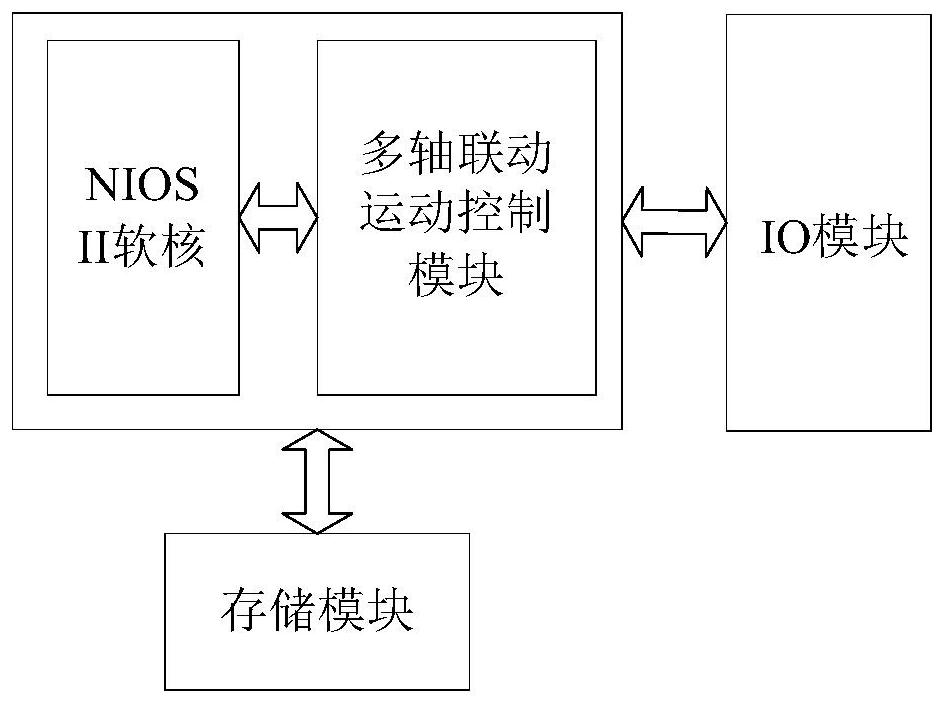

[0060] Such as image 3 As shown, an FPGA-based SOPC multi-axis linkage motion controller of the present invention includes a storage module, a soft core IP, a multi-axis linkage motion control module and an IO module.

[0061] Among them, the working principle of the multi-axis linkage motion control module is as follows: figure 2 shown.

[0062] In a specific implementation, the IO module includes a zero-return input module, and the zero-return input module is used to receive an external mechanical zero-return signal to realize the processing equipment to return to the mechanical origin.

[0063] In another embodiment, the IO module further includes a stepper motor control output module, which is connected to the multi-axis linkage motion control module, and directly drives the stepper motor through a stepper motor subdivision driver.

[0064] Specifically, the stepper motor control output module includes a plurality of output units with the same principle and controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com