Fault diagnosis method of catalytic cracking main draught fan group closed-loop control in petrochemical equipment

A catalytic cracking and closed-loop control technology, which is applied in the direction of program control, general control system, control/regulation system, etc., can solve the problems of weakened closed-loop effect of the external performance of faults, and the failure of the main fan unit of catalytic cracking cannot be effectively diagnosed, etc. To achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

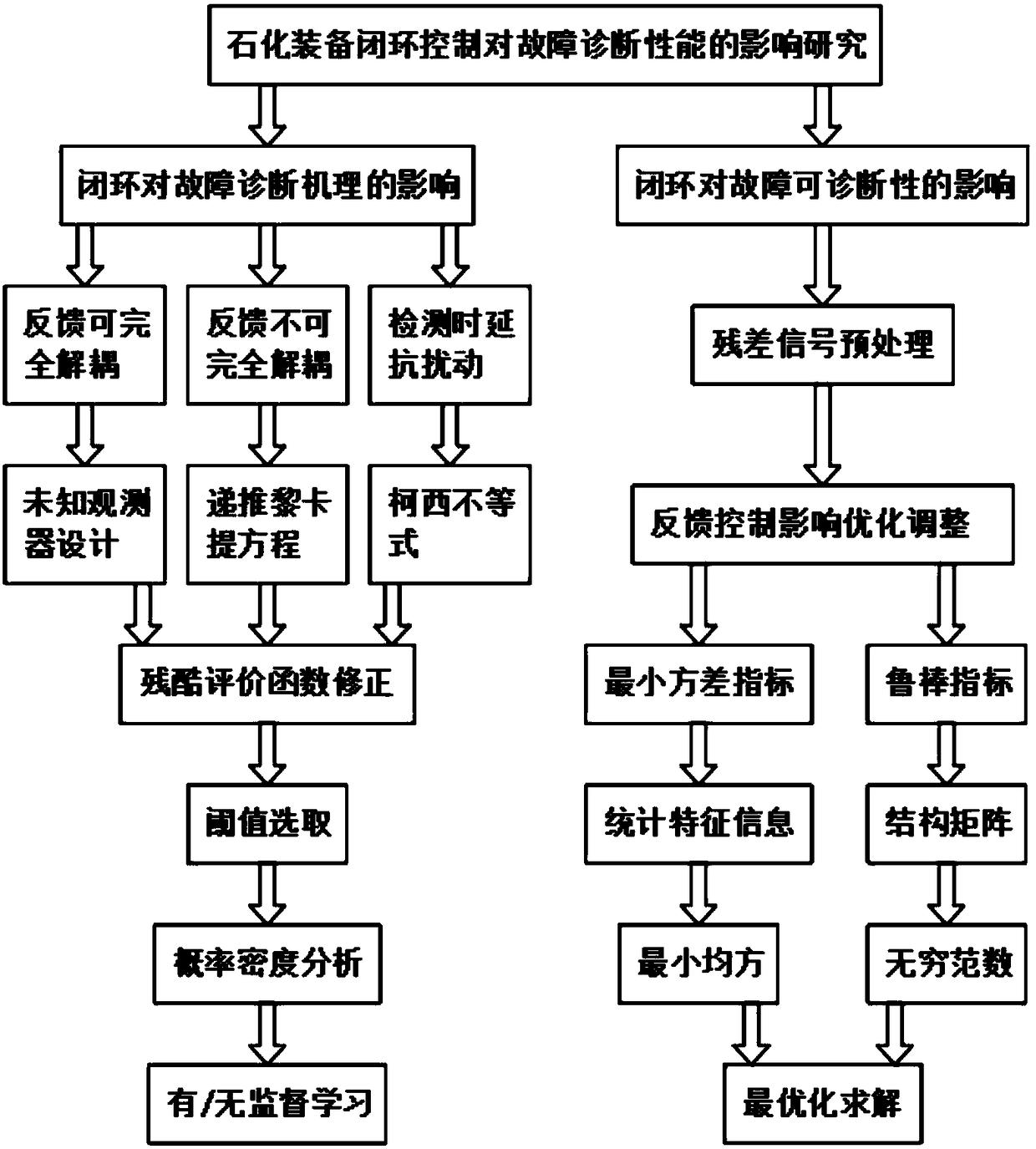

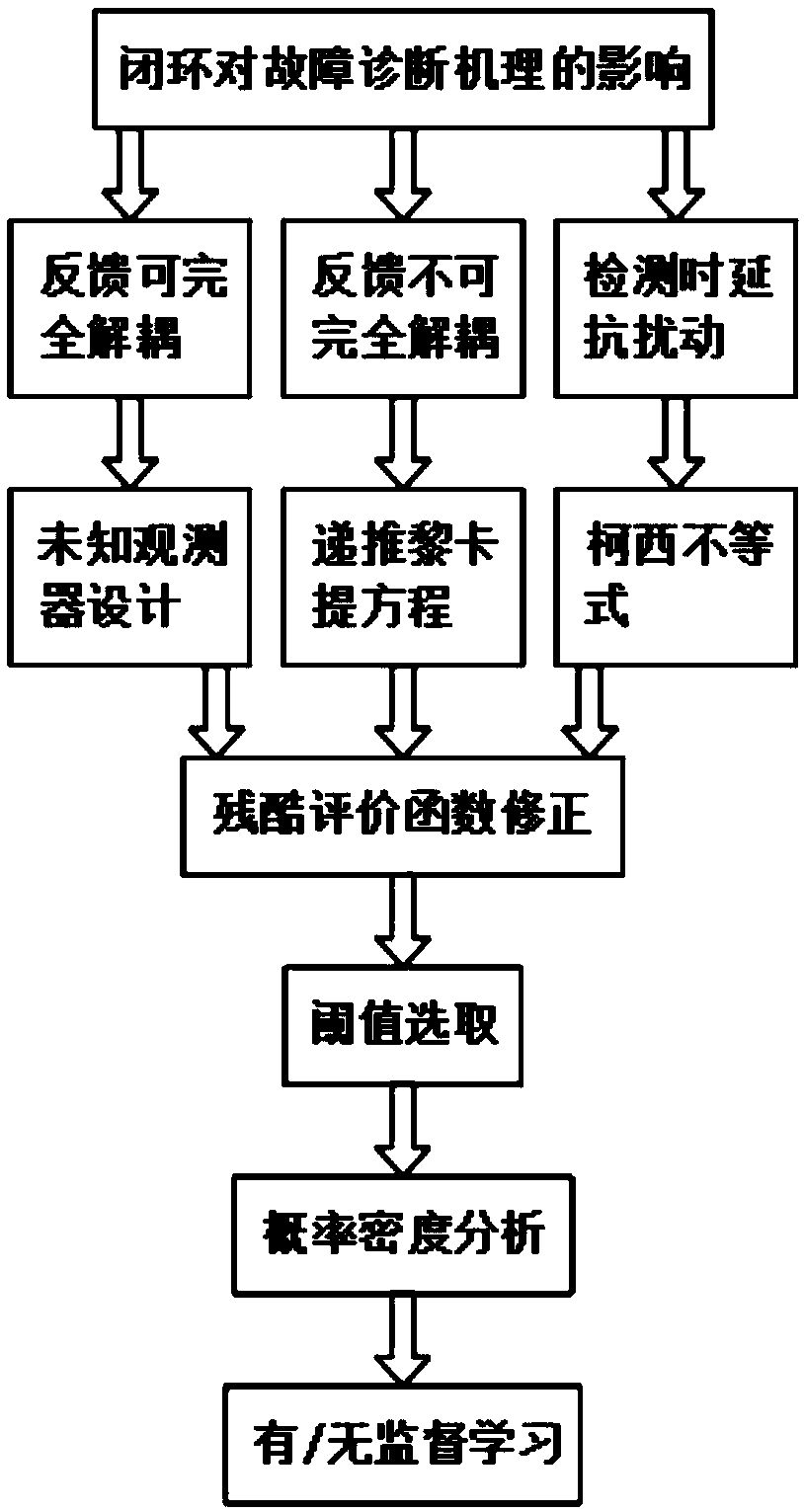

[0021] The present invention provides such Figure 1-3 A closed-loop control fault diagnosis method for the catalytic cracking main fan unit in petrochemical equipment is shown, which specifically includes the following steps:

[0022] Step 1: If the model uncertainty and nonlinear structural information are known, the method of unknown input observer can be adopted, so that the gain from the control signal to the residual signal is zero, that is, the residual signal is decoupled from the control signal;

[0023] Step 2: If the decoupling cannot be realized, the influence of the residual signal and uncontrollable factors can be made as small as possible in the sense of mathematical expectation or robust criterion, and the forward or reverse recursive Riccati equation can be used to solve it;

[0024] Step 3: Finally, the probability density function can be used to analyze the impact of this change on the fault false alarm rate and false negative rate in a statistical sense, an...

Embodiment 2

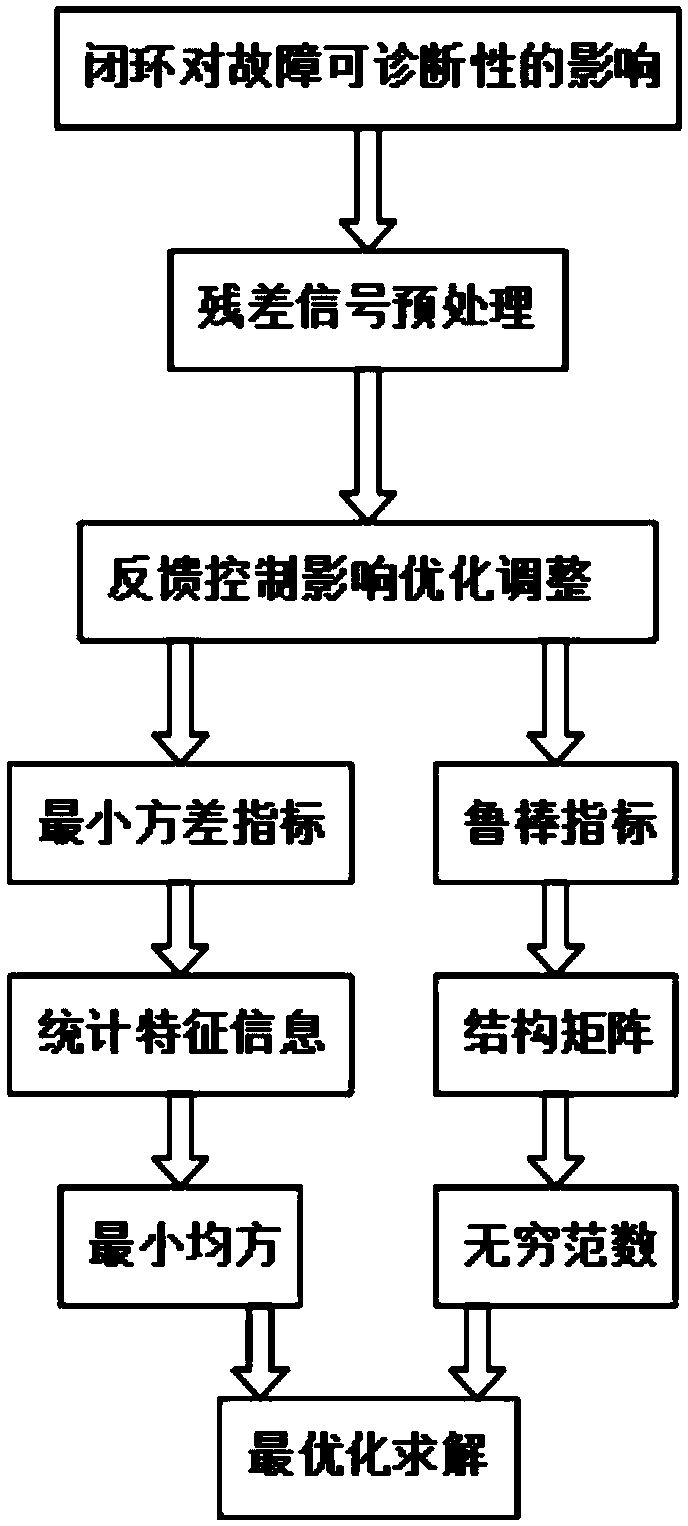

[0029] The present invention provides such Figure 1-3 A closed-loop control fault diagnosis method for the catalytic cracking main fan unit in petrochemical equipment is shown, which specifically includes the following steps:

[0030] Step 1: If the residual generator needs to consider other performance indicators such as detection delay and anti-disturbance, instead of simply considering reducing the impact of closed-loop feedback, it needs to use residual recursion to analyze historical feedback control through triangle inequality and Cauchy inequality For the worst possible impact of the residual magnitude and some eigenvalues, adjust the form of the residual evaluation function and the corresponding threshold;

[0031] Step 2: Finally, the probability density function can be used to analyze the impact of this change on the fault false alarm rate and false negative rate in a statistical sense, and the correlation analysis is carried out by using / unsupervised learning metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com