Anti-dropping tackle for electric transmission lines

A transmission line, anti-off technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as deformation, spring replacement procedures, lock plate can not be locked, etc., to improve structural flexibility, prevent position deviation, and reliable The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

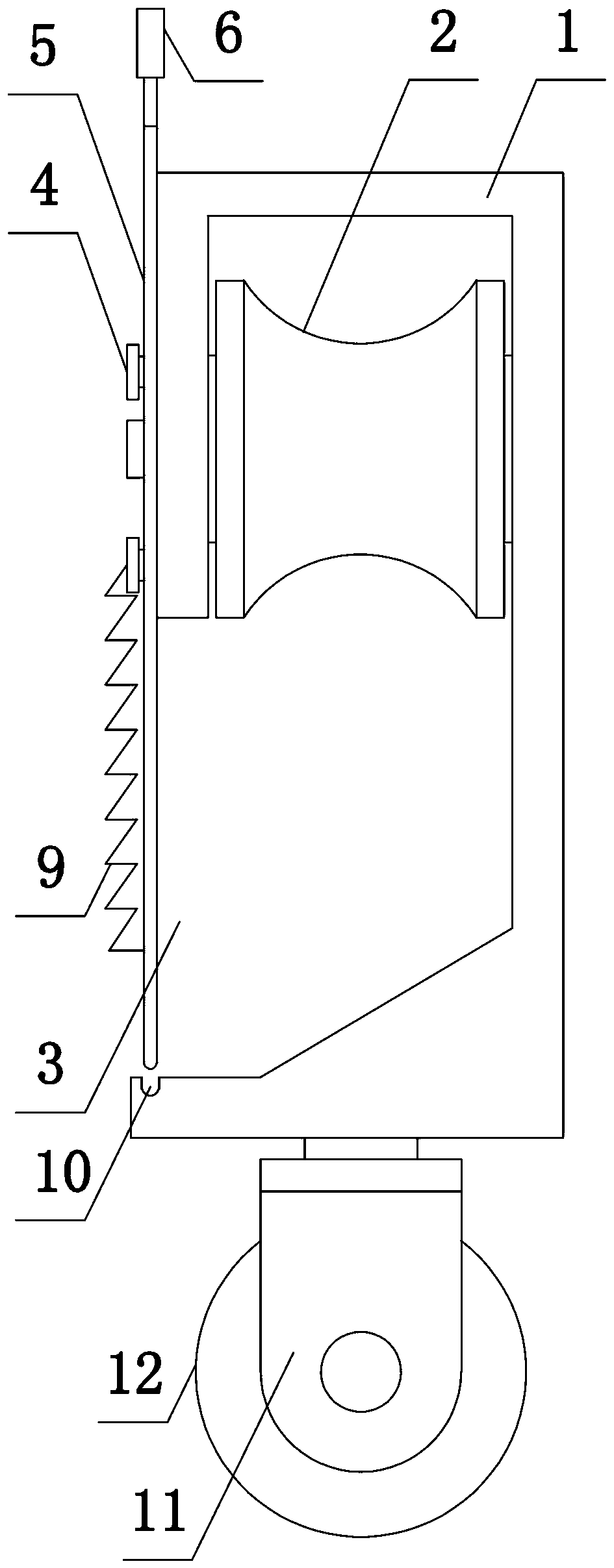

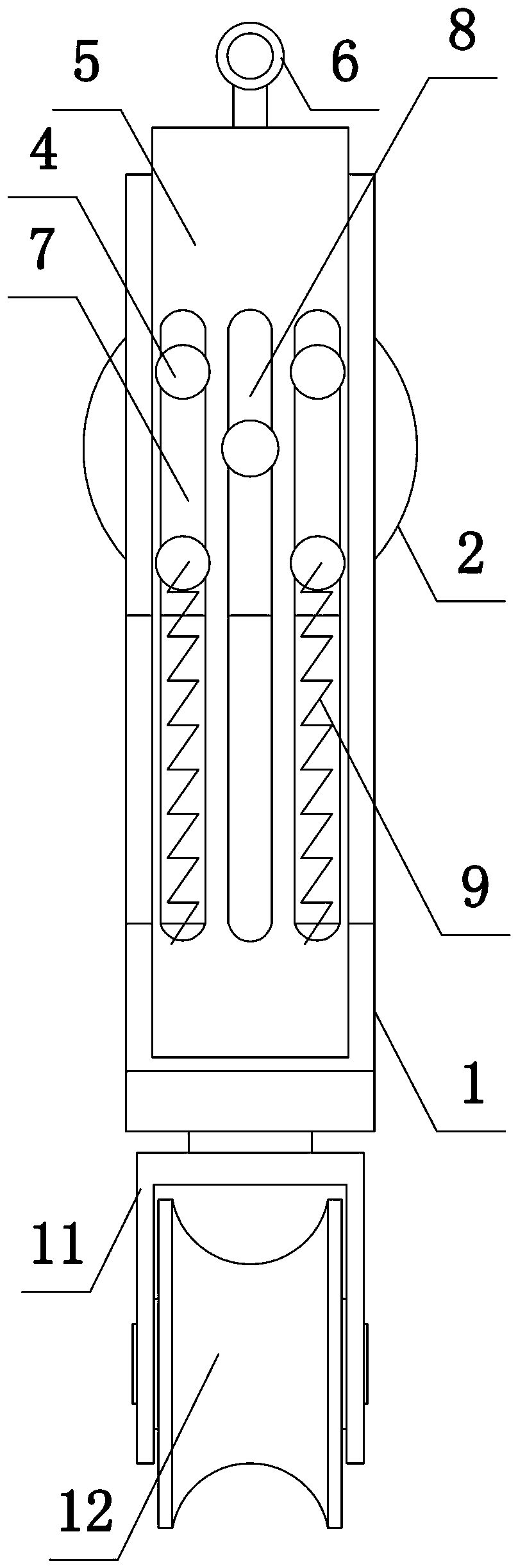

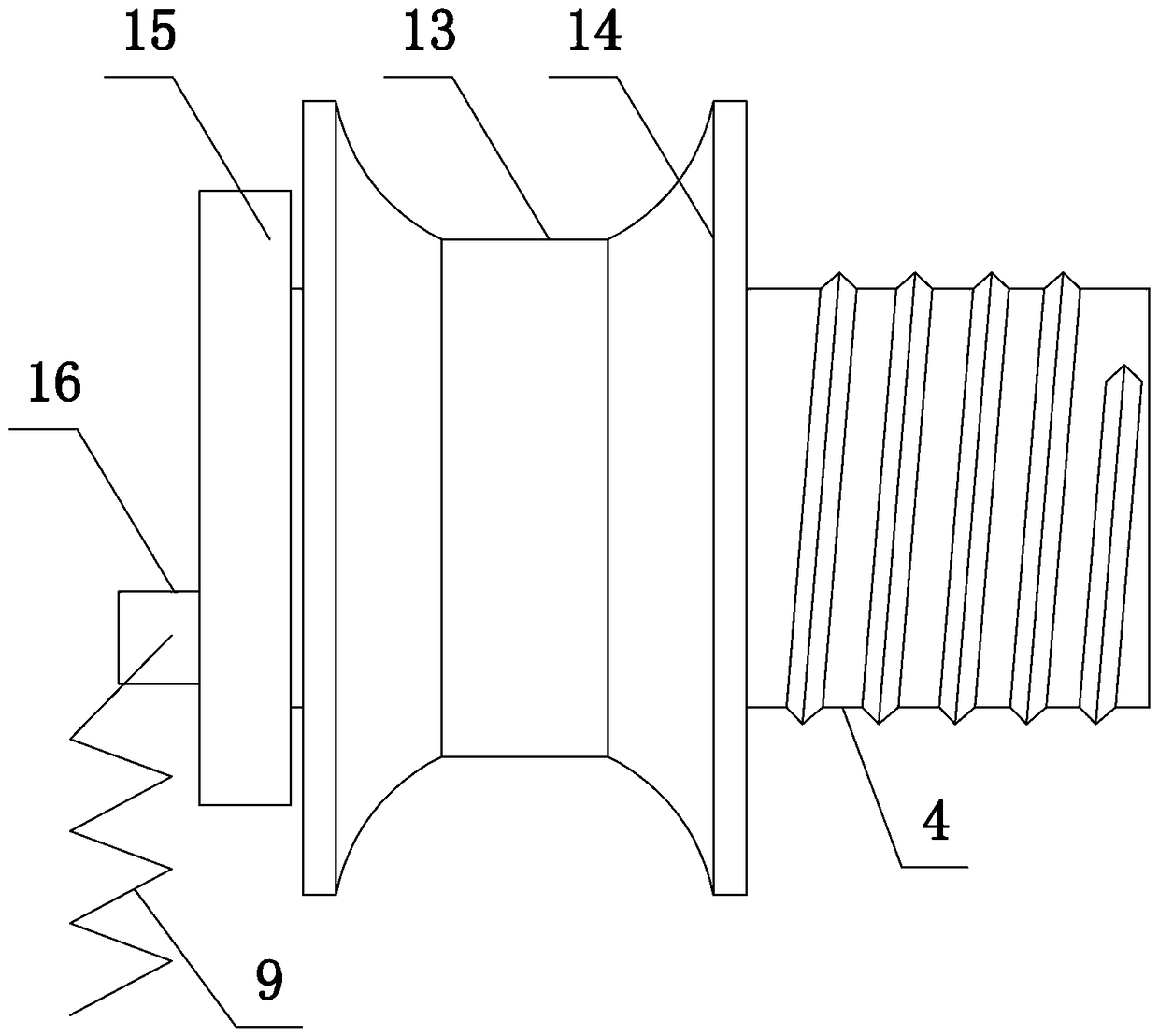

[0025] Such as figure 1 and figure 2 As shown, the present invention includes a hook 1, a suspension mechanism and a self-sealing mechanism. The first pulley 2 is installed in the hook 1, the hook 1 is provided with an opening 3, and the position of the hook 1 near the opening 3 is threaded to connect two sets of positioning columns 4, each group of positioning columns 4 is arranged in two along the vertical direction, and the self-sealing mechanism includes a sealing plate 5 and a lifting ring 6 welded on the upper end of the sealing plate 5, and two first elongated holes 7 and one second elongated hole 8 are opened on the sealing plate 5, Sliding fit between the positioning column 4 and the first elongated hole 7, the second elongated hole 8 provides a sliding space for the central axis of the first pulley 2, two springs 9 are fixed on the outer end surface of the sealing plate 5, and the other end of the spring 9 Fixedly connected with the positioning column 4, the hook 1...

Embodiment 2

[0027] The present invention comprises a hook 1, a suspension mechanism and a self-closing mechanism. A first pulley 2 is installed in the hook 1. An opening 3 is arranged on the hook 1. The position of the hook 1 close to the opening 3 is threaded to connect two sets of positioning columns 4, and each group of positioning columns 4 is connected vertically. The vertical direction is set to two, and the self-sealing mechanism includes a sealing plate 5 and a suspension ring 6 welded on the upper end of the sealing plate 5. Two first elongated holes 7 and a second elongated hole 8 are provided on the sealing plate 5, and the positioning column 4 Sliding fit with the first elongated hole 7, the third pulley is set between the sealing plate 5 and the positioning column 4, the second elongated hole 8 provides a sliding space for the central axis of the first pulley 2, and the outer end surface of the sealing plate 5 Two springs 9 are fixed, the other end of the spring 9 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com