High-performance large span cable bridge

A cable tray and large-span technology, applied in the direction of electrical components, can solve problems such as confusion, difficult placement, and influence on cable maintenance and repair, and achieve the effects of neat placement, increased quantity, and easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

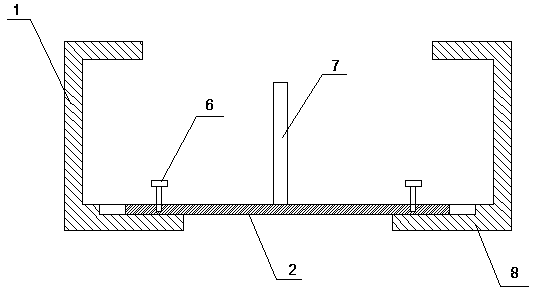

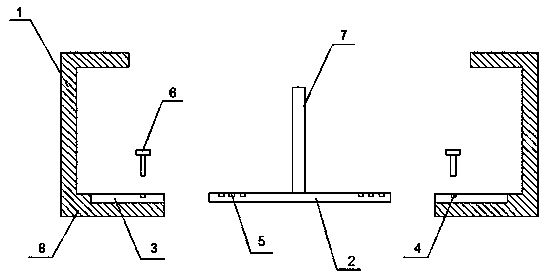

[0029] This embodiment provides a high-performance long-span cable bridge, including a bridge body, and the bridge body includes two opposite ladder sides 1 and a horizontal plate 2 installed between the two ladder sides 1, and the lower end of each ladder side 1 is There is a horizontal folded edge 8, and the end of the folded edge 8 close to the horizontal plate 2 is provided with a horizontal clamping groove 3, and the left and right sides of the horizontal plate 2 are slidingly arranged in the clamping grooves 3 of the two ladder sides 1 respectively. Adjusting the width of the horizontal plate 2 extending into the card slot 3 can adjust the distance between the two ladder sides 1 .

[0030] On the horizontal plate 2, the left side and the right side are respectively provided with three limiting holes one 4, and these limiting holes one 4 are evenly arranged along the width direction of the horizontal plate 2, and the clamping groove 3 is provided with two limiting holes 5,...

Embodiment 2

[0038] This embodiment provides a high-performance long-span cable bridge, including a bridge body, and the bridge body includes two opposite ladder sides 1 and a horizontal plate 2 installed between the two ladder sides 1, and the lower end of each ladder side 1 is There is a horizontal folded edge 8, and the end of the folded edge 8 close to the horizontal plate 2 is provided with a horizontal clamping groove 3, and the left and right sides of the horizontal plate 2 are slidingly arranged in the clamping grooves 3 of the two ladder sides 1 respectively. Adjusting the length of the horizontal plate 2 extending into the card slot 3 can adjust the distance between the two ladder sides 1 .

[0039]On the horizontal plate 2, the left side and the right side are respectively provided with three limiting holes one 4, and these limiting holes one 4 are evenly arranged along the width direction of the horizontal plate 2, and the clamping groove 3 is provided with two limiting holes 5,...

Embodiment 3

[0047] This embodiment provides a high-performance long-span cable bridge, including a bridge body, and the bridge body includes two opposite ladder sides 1 and a horizontal plate 2 installed between the two ladder sides 1, and the lower end of each ladder side 1 is There is a horizontal folded edge 8, and the end of the folded edge 8 close to the horizontal plate 2 is provided with a horizontal clamping groove 3, and the left and right sides of the horizontal plate 2 are slidingly arranged in the clamping grooves 3 of the two ladder sides 1 respectively. Adjusting the length of the horizontal plate 2 extending into the card slot 3 can adjust the distance between the two ladder sides 1 .

[0048] On the horizontal plate 2, the left side and the right side are respectively provided with three limiting holes one 4, and these limiting holes one 4 are evenly arranged along the width direction of the horizontal plate 2, and the clamping groove 3 is provided with two limiting holes 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com