a motor

A magnetic pole and rotor technology, applied in the field of motor equipment, can solve the problems of weakening the electromagnetic pull of the motor rotor, reducing the heating loss of the winding, reducing the motor, etc., achieving a stable and quiet working state, reducing noise, and reducing the winding space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above objectives, technical solutions and beneficial effects clearer, the present invention will be described in detail below in conjunction with the accompanying drawings.

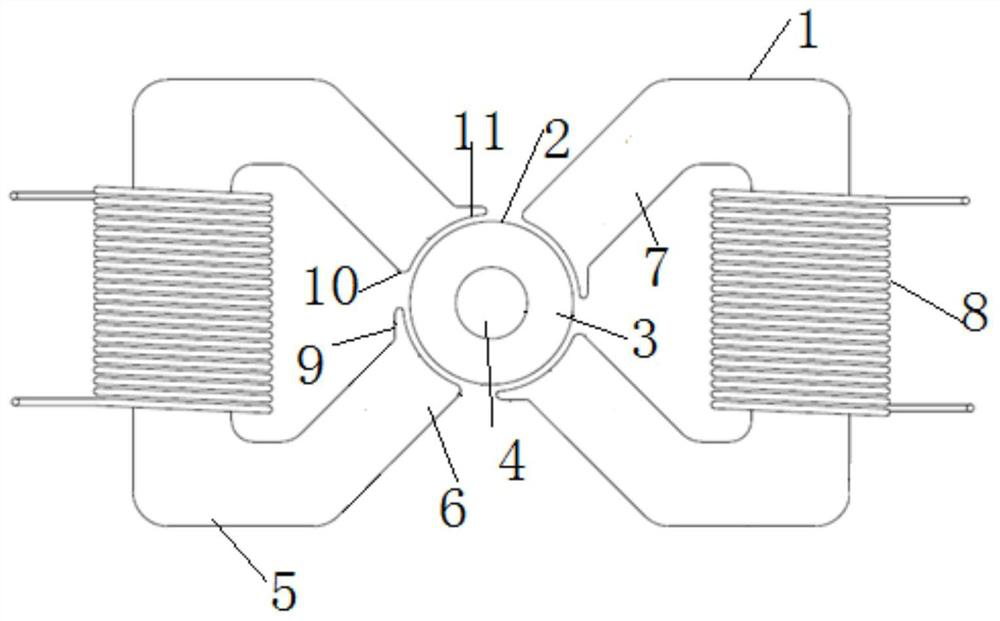

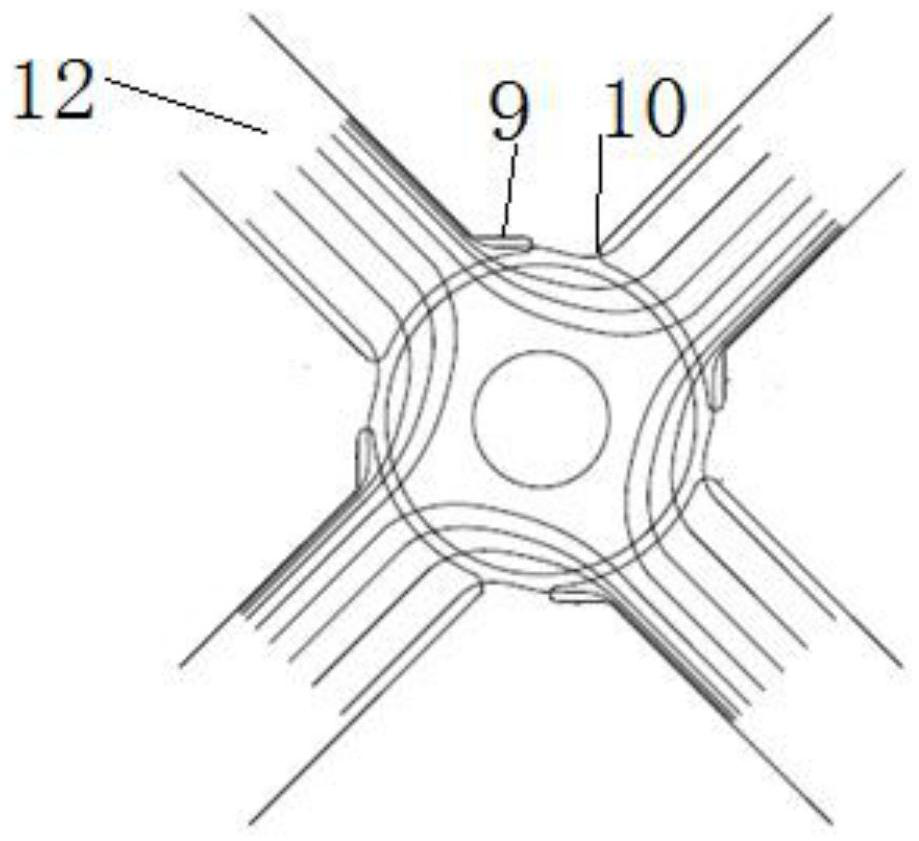

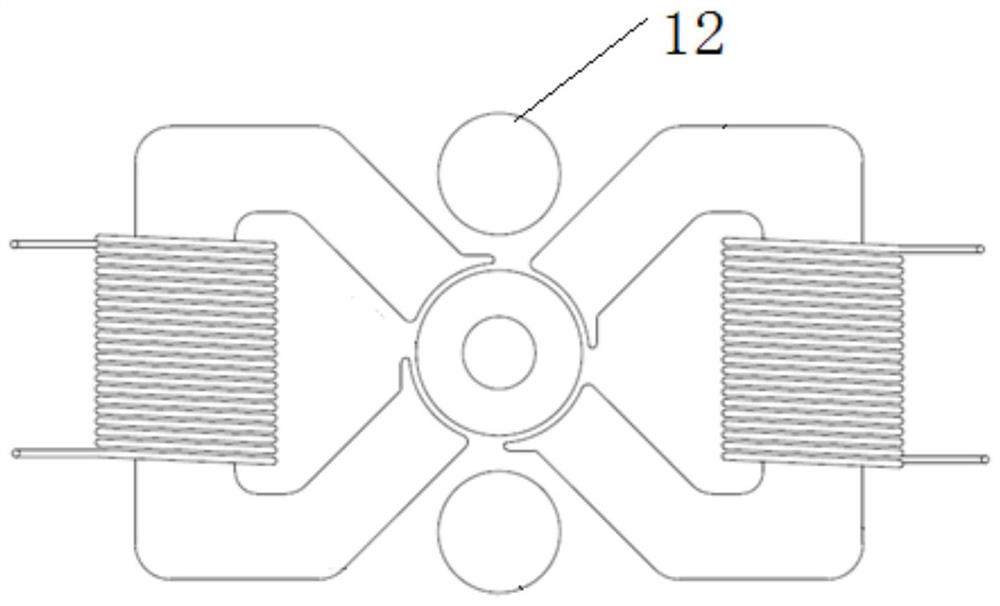

[0020] Such as figure 1 As shown, the motor includes a rotor 2 and a stator 5, the rotor 2 includes a four-pole annular permanent magnet 3 supported on a central shaft 4, the stator 5 includes a stator core 6 and a winding 8 wound on the stator core , the stator core 6 is a triangular shape with a slot opening, including the back and the adjacent magnetic poles 7 separated by the slot opening, the angle between the central axes of two adjacent magnetic poles 7 is 90 degrees, and the four magnetic poles 7 are perpendicular to each other, which can be greatly improved. Weaken the lateral electromagnetic pull of the rotor 2, so that the motor runs smoothly and with low noise. The windings 8 are respectively wound on the back of the stator core 6. Each magnetic pole 7 has a magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com