Mercury removal method for flue gas

A technology of flue gas and mercury removal agent, which is applied in the field of flue gas mercury removal, and can solve the problems such as the adverse effect of hydrogen sulfide on the conversion process of sulfuric acid system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

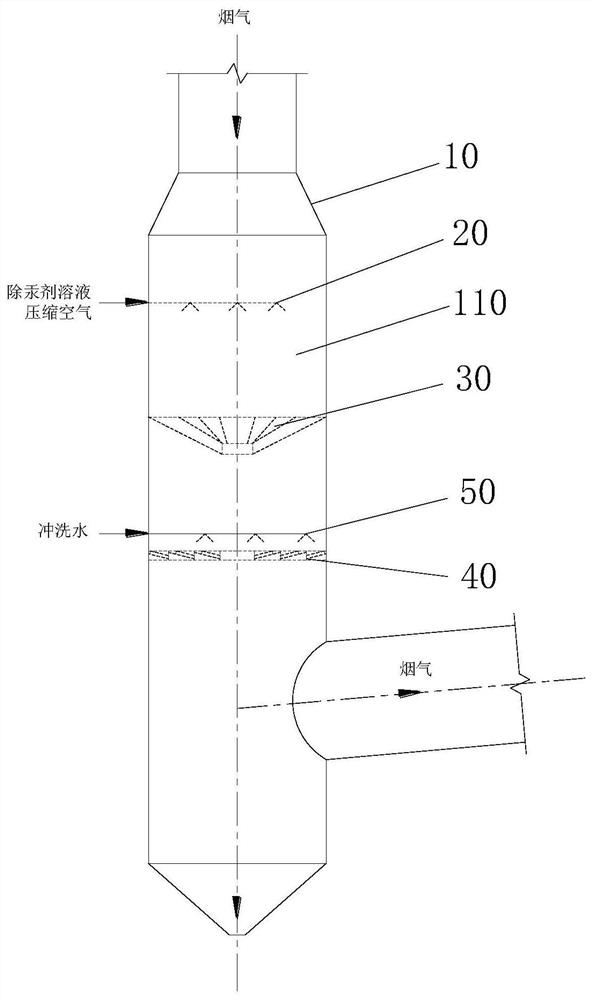

[0071]The mercaler mercaler of this embodiment includes the following steps:

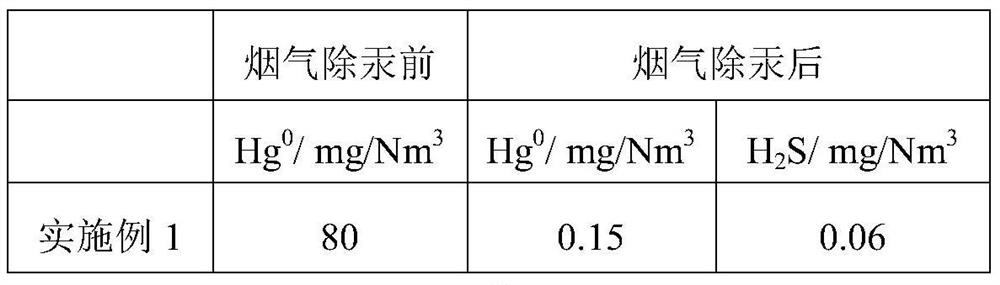

[0072]Single tabular mercury in flue gas 80mg / nm3, Moisture in the flue gas is close to saturation, composite amarant adopts Na2S and NA2S2O3And the mixed solution is configured with water, the mass concentration of the compound divided by the mercury in the solution is 4%, and a high pressure injector is provided in the mercury reactor, and the flue gas is transferred into the reactor, and the flow rate is 1.5 m / s. The composite ammurne is inserted into the high pressure injector and is in contact with the flue gas. The injection pressure is 0.2 MPa, and the reaction temperature of the smoke ammiacal is 23 ° C.

Embodiment 2

[0074]The difference between the mercury mercury and the first embodiment provided in this example is:

[0075]The mass concentration of the compound divided by the mercury containing the compound divider is 5%.

Embodiment 3

[0077]The difference between the mercury mercury and the first embodiment provided in this example is:

[0078]The mass concentration of the compound divided by the mercury in a mixed solution containing a composite amarant agent is 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com