Novel press-wheel type grinding fixture device

A technology of grinding jigs and pressure wheels, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of low product qualification rate and increased processing costs of enterprises, and achieve the effects of good versatility, reduced processing costs, and reasonable positioning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

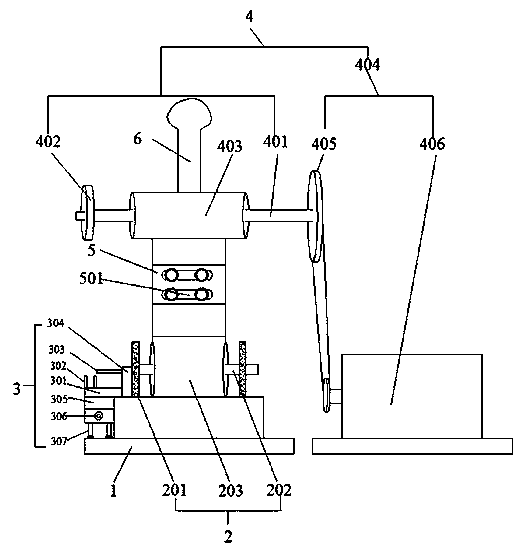

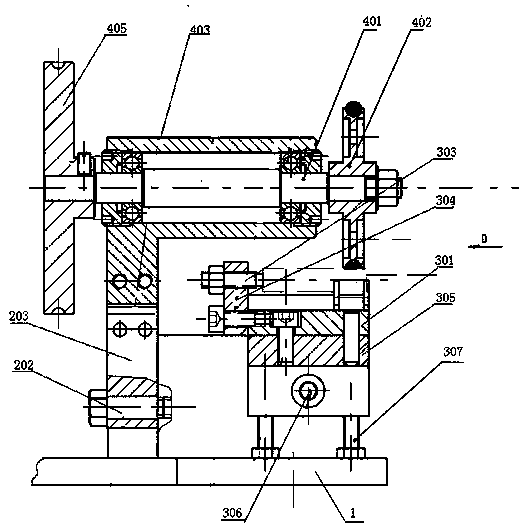

[0028] Such as Figure 1-2 As shown, a new press wheel type grinding fixture device includes a base plate 1 on which a support base 2, a workpiece placement device 3, and a workpiece pressing drive device 4 located above the support base 2 and the workpiece placement device 3 are provided. ;

[0029] The support base 2 includes support plates 201 arranged in parallel and a swing shaft 202 arranged between the support plates 201, the swing shaft 202 is rotatably connected in the swing block 203;

[0030] The workpiece placement device 3 includes a workpiece placement platform 301 fixedly connected to the base plate 1, a pair of vertical plates 302 arranged in parallel are fixed on one side of the upper end of the workpiece placement platform 301, and the vertical panels 302 arranged in parallel are symmetrically arranged with V-shaped The notch, the opposite side of the parallel vertical plate 302 and the workpiece placement platform 301 side are provided with a horizontal eje...

Embodiment 2

[0034] Such as figure 1 As shown, with respect to embodiment 1, the further improvement of embodiment 2 relative to embodiment 1 is that the bottom of the workpiece placement table 301 is fixed to the support seat 2 through the L-shaped plate 305, and the horizontal plate of the L-shaped plate 305 Fixed on the bottom of the workpiece placement table 301, the vertical plate of the L-shaped plate 305 is provided with a strip-shaped through hole, and the fixing bolt A306 passes through the strip-shaped through-hole and is fixed to the support seat 2; the vertical plate of the L-shaped plate 305 An adjusting rod 307 is arranged between the bottom of the straight plate and the top surface of the base plate 1. The adjusting rod 307 is an adjusting bolt, and the adjusting bolt passes through the threaded hole at the bottom of the L-shaped plate 305 to adjust. The top surface of the bottom plate 1 is in contact, and the adjustment rod (307) adjusts the height of the workpiece placemen...

Embodiment 3

[0037] Compared with Example 1, the further improvement of Example 3 relative to Example 1 is that the surface of the shaft sleeve 403 is fixed with a handle 6 for easy operation, and the base plate 1 is located on the workpiece placement table 301 facing away from the support seat 2 One side is fixed with a connecting rod, the handle 6 is arranged on the side of the shaft sleeve 403 facing the workpiece placement table 301, an elastic member is connected between the connecting rod and the handle 6, and the elastic member is provided with a pre-tension force, so The elastic member is an elastic rubber belt, so that the pressure roller 402 and the surface of the workpiece to be processed are kept in a good compression state;

[0038] All the other implementations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com