Manufacturing method for composite tailplane of small and medium size unmanned aerial vehicles

A technology of composite materials and horizontal fins, which is applied in the direction of household components, household appliances, and other household appliances, to achieve the effects of simplifying the molding process, reducing quality risks, and reliable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

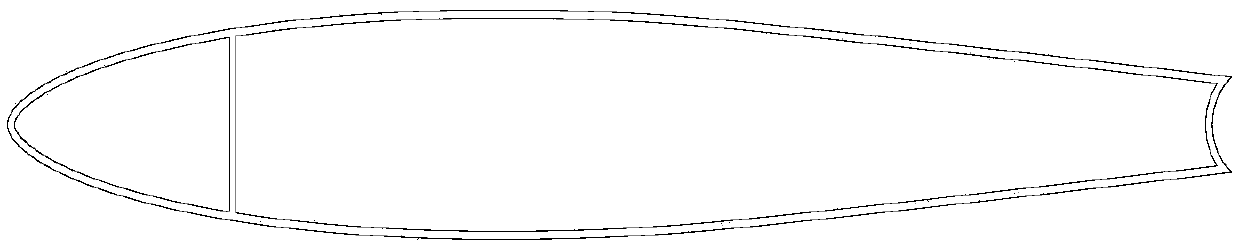

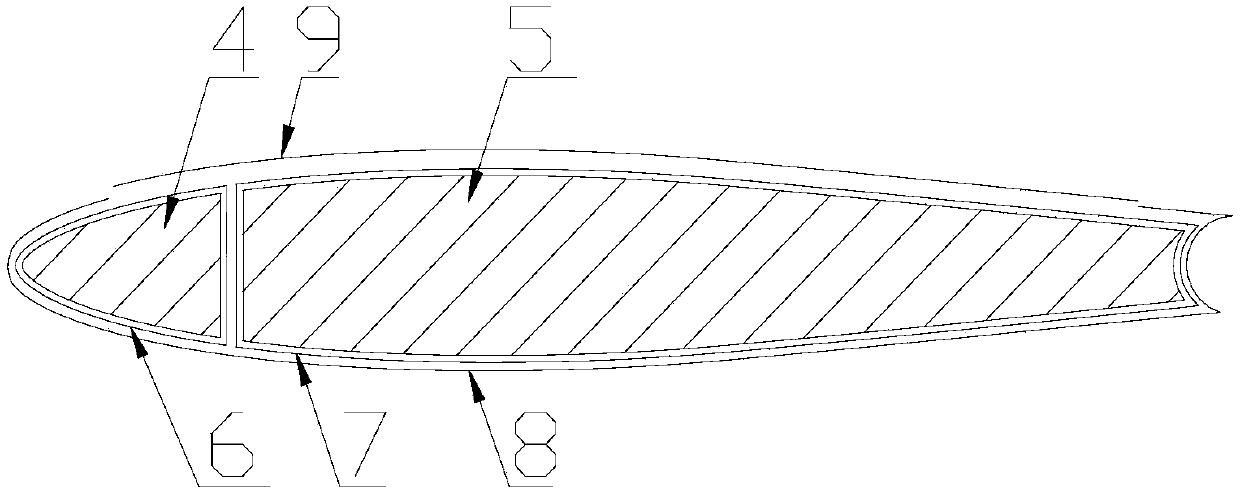

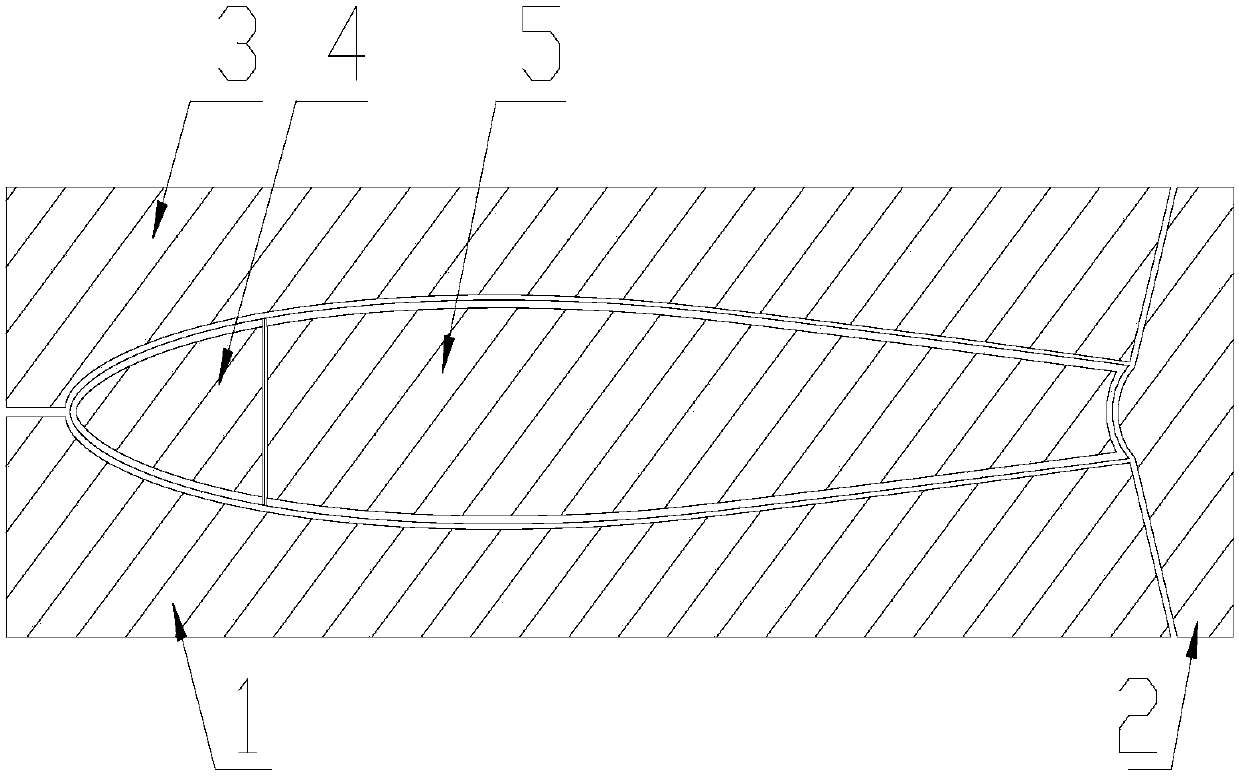

[0032] see Figure 1-Figure 3 , the technical solution of the present invention is: a kind of manufacturing method of composite material horizontal tail of small and medium-sized unmanned aerial vehicles, and this process comprises the following steps:

[0033] Step 1, tooling design: According to the structural characteristics of the product, use CATIA software for 3D modeling and tooling design, and process the tooling mold according to the digital model to obtain the overall forming mold. The tooling design adopts block design to ensure process molding and product demoulding.

[0034] The auxiliary tooling for manufacturing the silicone rubber core mold includes a metal plate and a false beam. The metal plate is located at the end of one end of the assembled integral molding mold, and has the same cross-section as the end face; Between the rubber molding mandrel 5, it is used to replace the beam structure in the product, and its external dimensions are determined by the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com