Bag-introducing groove for inn and outer package

A technology for introducing grooves and packaging bags, which is applied in the field of introducing grooves for inner and outer packaging bags, which can solve the problems of affecting packaging efficiency and high labor intensity of workers, and achieve the effect of improving efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

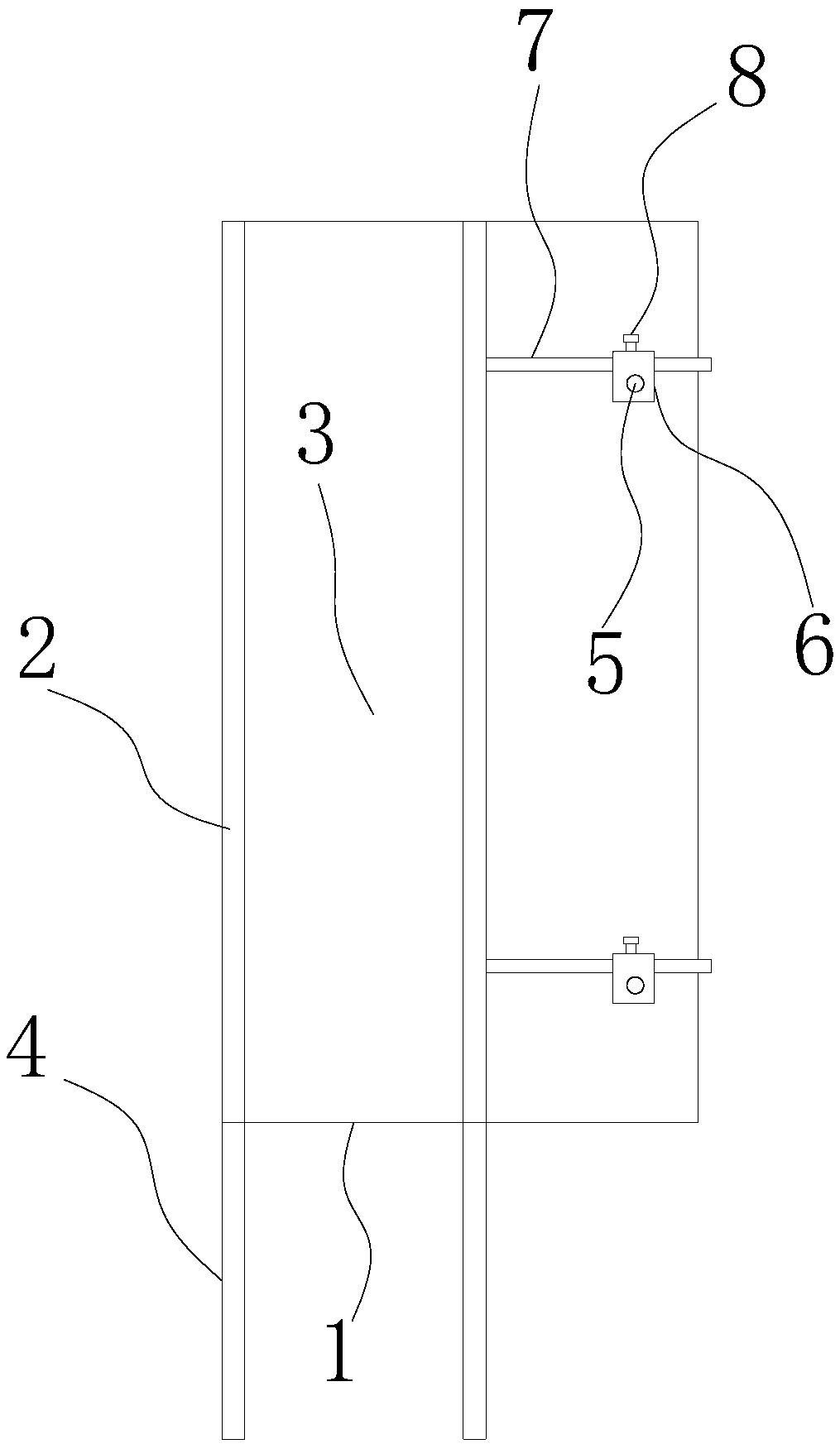

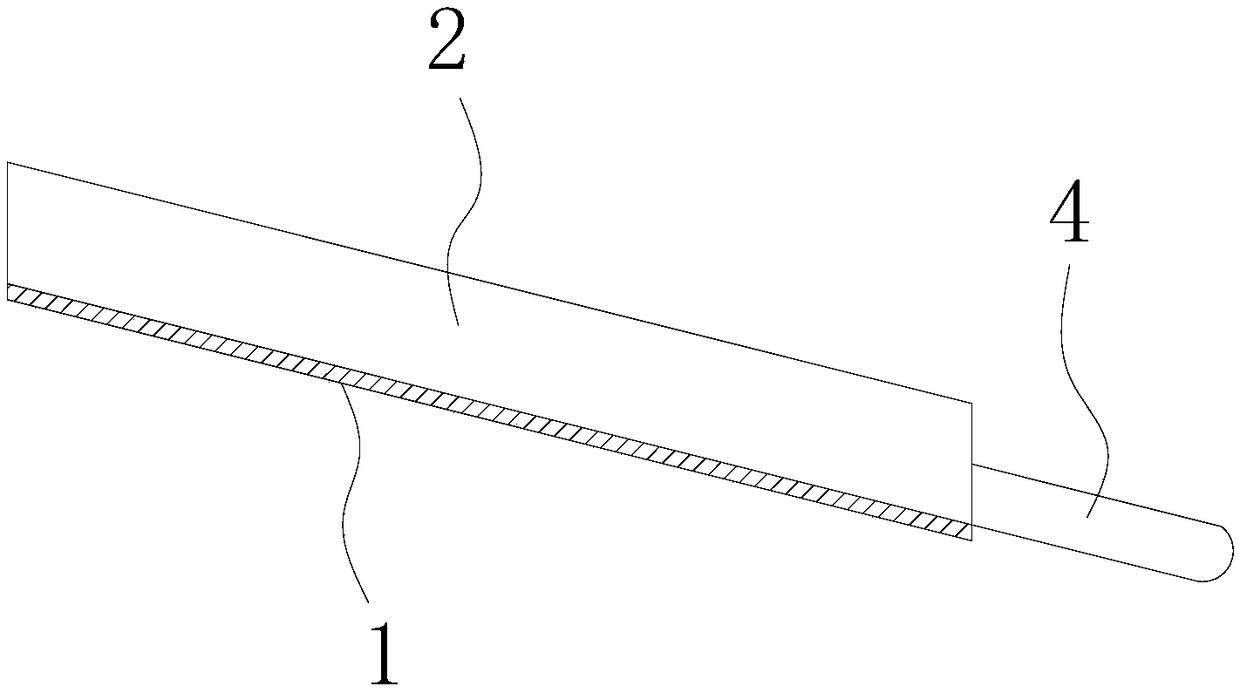

[0020] The inner and outer packaging bag import groove of the present embodiment, such as figure 1 and figure 2 As shown, it includes an inclined guide plate 1 including an upper feed end and a lower outlet end. The guide plate 1 is provided with baffles 2 in pairs on both lateral sides. The blanking channel 3 at the end; the both sides of the outlet end of the blanking channel 3 are respectively provided with an elastic support plate 4, and the bottom of the elastic support plate 4 stretches out from the guide plate 1; the distance between the elastic support plates 4 on both sides of the outlet end and The width of the inner packaging bag is adapted, and the height of the elastic support plate 4 is adapted to the height of the inner packaging bag.

[0021] The guide plate 1 can be made of a metal plate with a smooth surface, which is used to convey the inner packaging bag for packing grain, and can be installed on the frame. The inclination angle is determined according to...

Embodiment 2

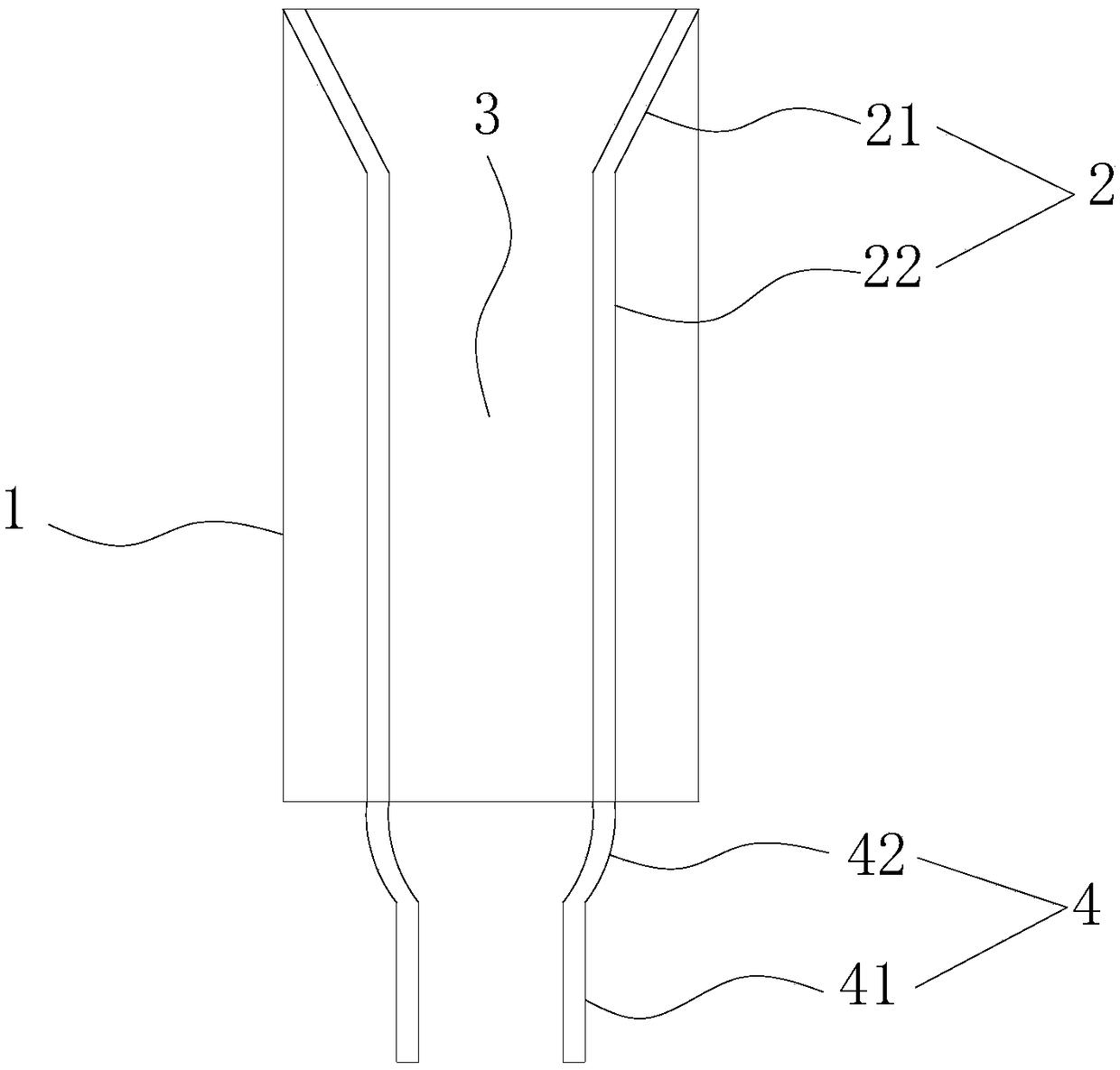

[0029] The inner and outer packaging bag import groove of the present embodiment, such as image 3 As shown, it includes an inclined guide plate 1 including an upper feed end and a lower outlet end. The guide plate 1 is provided with baffles 2 in pairs on both lateral sides. The blanking channel 3 at the end; the both sides of the outlet end of the blanking channel 3 are respectively provided with an elastic support plate 4, and the bottom of the elastic support plate 4 stretches out from the guide plate 1; the distance between the elastic support plates 4 on both sides of the outlet end and The width of the inner packaging bag is adapted, and the height of the elastic support plate 4 is adapted to the height of the inner packaging bag. The baffle plate 2 includes a guide section 21 and a limit section 22, the lower end of the guide section 21 is connected to the upper end of the limit section 22, the distance between the upper ends of the guide sections 21 of each pair of baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com