Ultrasonic no-clean kitchen ventilator without pipe and cooking fume filtering and removal method

An ultrasonic and range hood technology, which is applied in the directions of removing oil fume, heating method, lighting and heating equipment, etc., can solve the problems of not being able to draw oil fume exhaust gas well, reducing the suction function of the range hood, and reducing the air quality of the kitchen, etc. Achieve the effect of eliminating manual cleaning and maintenance, achieving sustainable development and flexible installation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

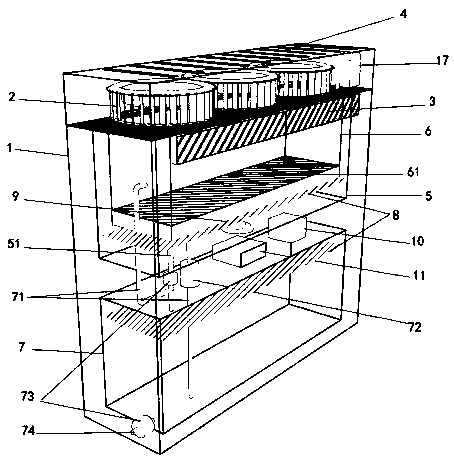

[0025] like figure 1 figure 2 As shown, a ductless ultrasonic no-cleaning range hood 1 provided in the embodiment of the present invention mainly includes: a casing (1), a fan (2), a suction port (3), an exhaust port (4), Oil fume filtering device (6), oil fume cleaning device (5), water tank (7).

[0026] The suction port (3) is located at the top of the front of the casing (1), and the overall shape is a long slot or multiple rows of holes distributed at equal intervals, and can also be set to other types according to specific design methods. shape. One side of the suction port (3) can be set as a concave structure with a gradient curved surface, so as to facilitate the concentration of the suction wind and ensure the effect of oil fume suction.

[0027] The housing (1) also includes an oil fume cleaning device (5) connected to the suction port (3) for cleaning oil fume, and the oil fume cleaning device (5) is connected to the filter by means of outer nesting. The fan (...

specific Embodiment 2

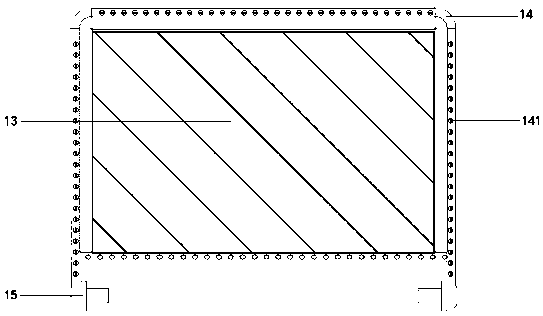

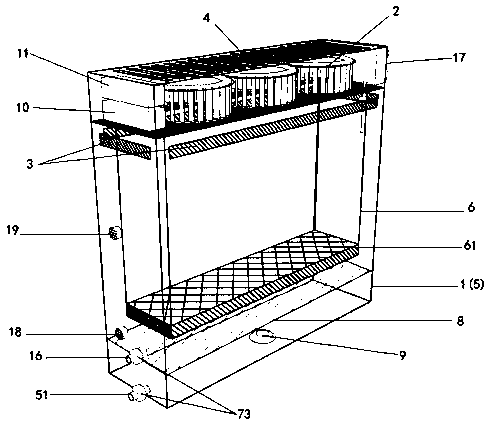

[0040] like image 3 Figure 4 As shown, the main features of a ductless ultrasonic free-cleaning range hood 2 provided in the embodiment of the present invention are the same as those of the specific embodiment 1, except that the two sides of the casing (1) further include two parallel arranged The air inlet (12) communicated with the oil fume cleaning device (5) further comprises a transparent cover plate (13), the bottom side edge of the transparent cover plate (13) is provided with a hollow suction duct (14) , the suction duct (14) is connected with the air inlets (12) on both sides of the casing (1) through a rotating shaft (15), and the transparent cover (13) can effectively prevent oil and gas from contacting the human respiratory tract and prevent heat The splash of oil can hurt the human body, protect the health of the cook, and prevent the fumes from escaping. In addition to the suction port (3) above the front of the housing (1), the suction duct (14) is also prov...

specific Embodiment 3

[0041] like Figure 5 Image 6 As shown in the figure, the main features of a ductless ultrasonic free-cleaning range hood 3 provided in the embodiment of the present invention are the same as those of the specific embodiment 1, except that the lampblack cleaning device (5) and the range hood described in the specific embodiment 1 are removed. The water tank (7) and the casing (1) are directly replaced as the oil fume cleaning device (5) in the specific embodiment 1, and the casing (1) includes a water inlet (16) and a water outlet (51) , the water pump (72), the water pipe (71) and the faucet valve (73) can automatically add tap water into the shell (1) by connecting an external faucet, and discharge the needs after cleaning through the drain port (51). Replacement fluid. A cleaning solution (8) storage box is further included above the housing (1), and the cleaning solution (8) storage box can automatically squeeze a suitable concentrated cleaning solution into the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com