Copper plate assembling device

A technology for assembling devices and copper plates, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of error-prone placement, production equipment downtime and long waiting time, and high labor intensity, so as to avoid unstable surface quality, Avoid placement errors and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

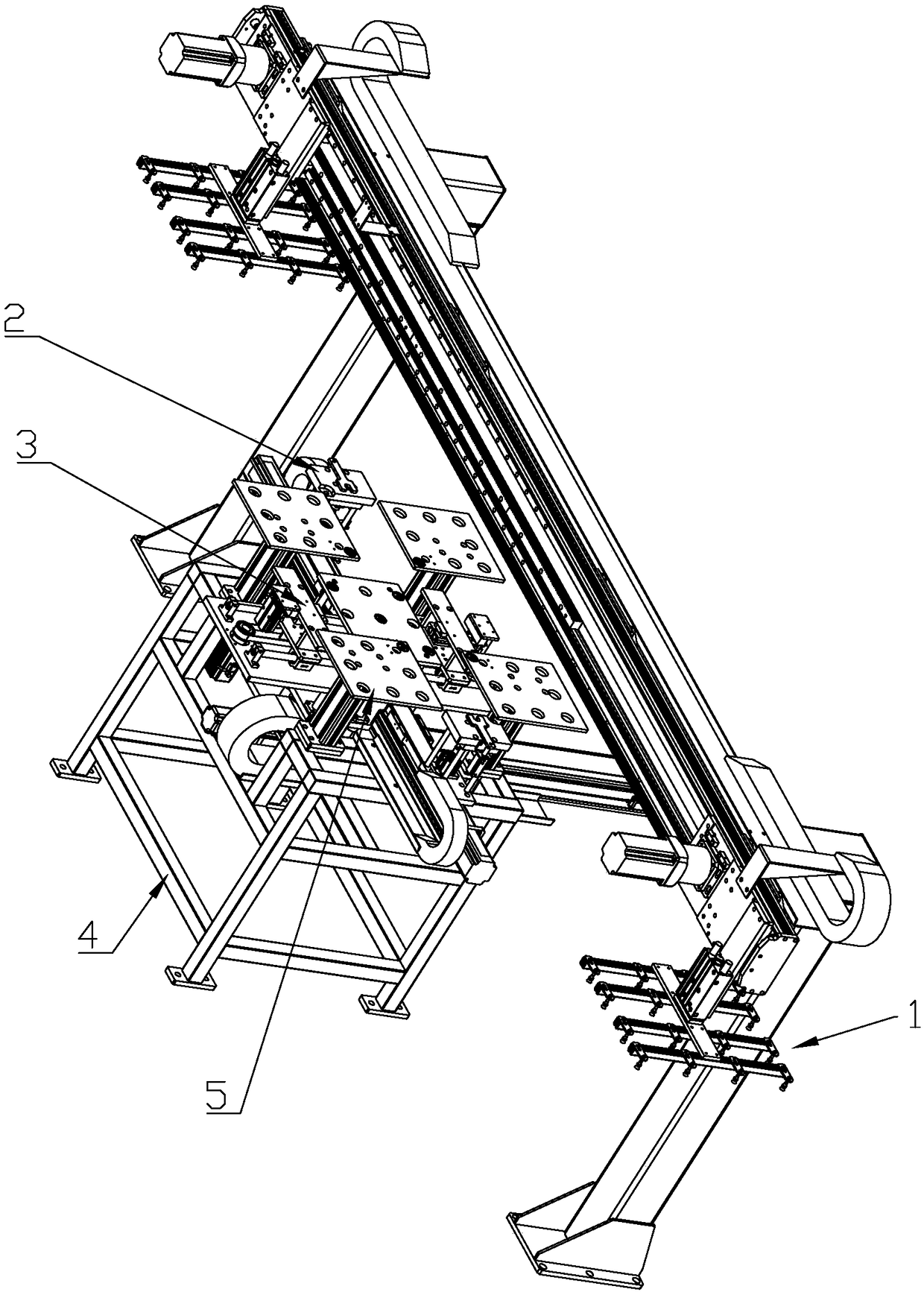

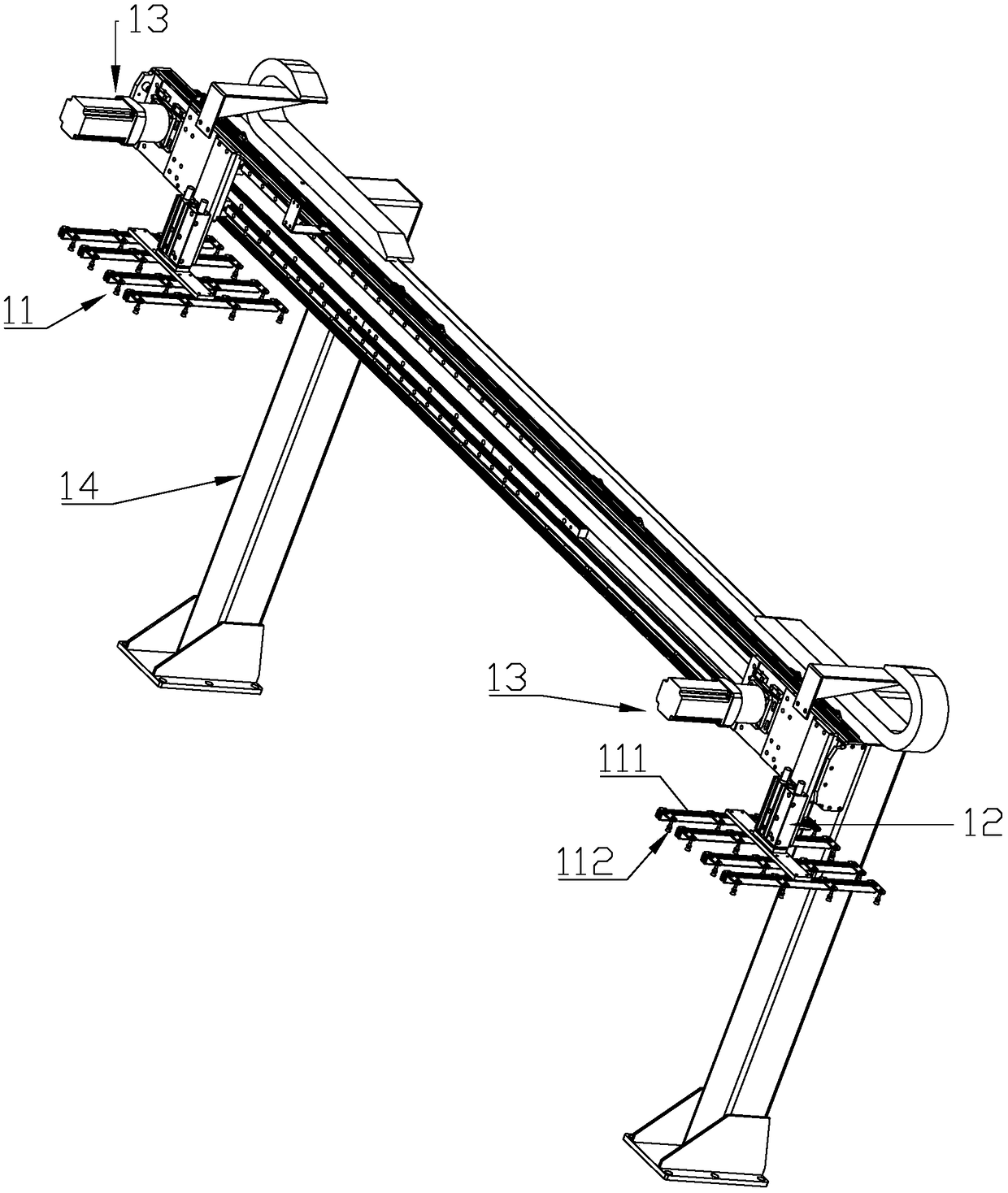

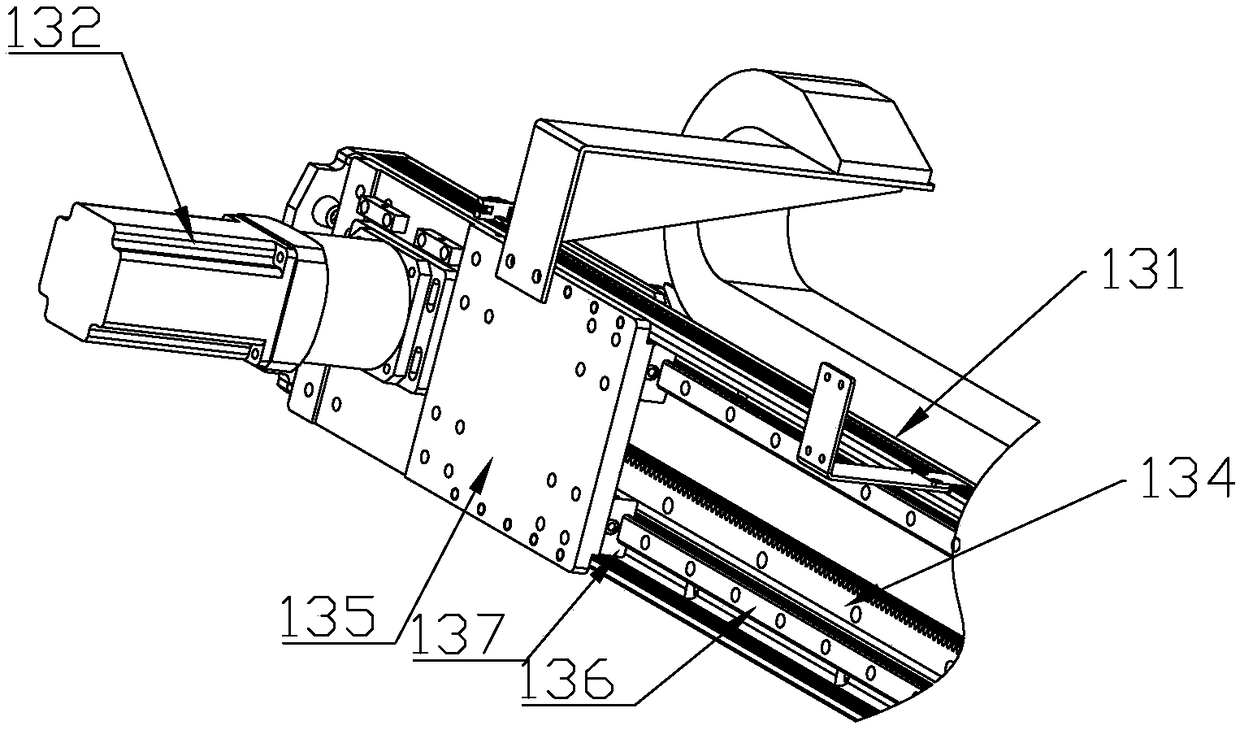

[0036] Refer to the attached figure 1 to attach Figure 9 The copper plate assembly device of the present invention will be described in detail below.

[0037] The copper plate assembling device of the present invention, its structure comprises assembling and transplanting manipulator 1, assembling and positioning mechanism 2, clamping and transplanting mechanism 3, assembling supporting frame 4 and assembling supporting plate 5, described assembling and positioning mechanism 2, clamping and transplanting The mechanism 3 and the assembly support plate 5 are respectively arranged on the assembly support frame 4 , and the assembly transplanting manipulator 1 is arranged on the upper part of the assembly positioning mechanism 2 .

[0038] The described assembling and transplanting manipulator 1 comprises copper plate assembling and transplanting vacuum suction cup group 11, assembling and transplanting lifting cylinder 12, assembling and transplanting horizontal moving drive mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com