CCD visual positioning apparatus

A visual positioning and visual technology, applied in the direction of the camera device, etc., can solve the problems of error-prone placement, production equipment downtime and long waiting time, and high labor intensity, so as to avoid unstable surface quality, avoid wrong placement position, and reduce labor. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

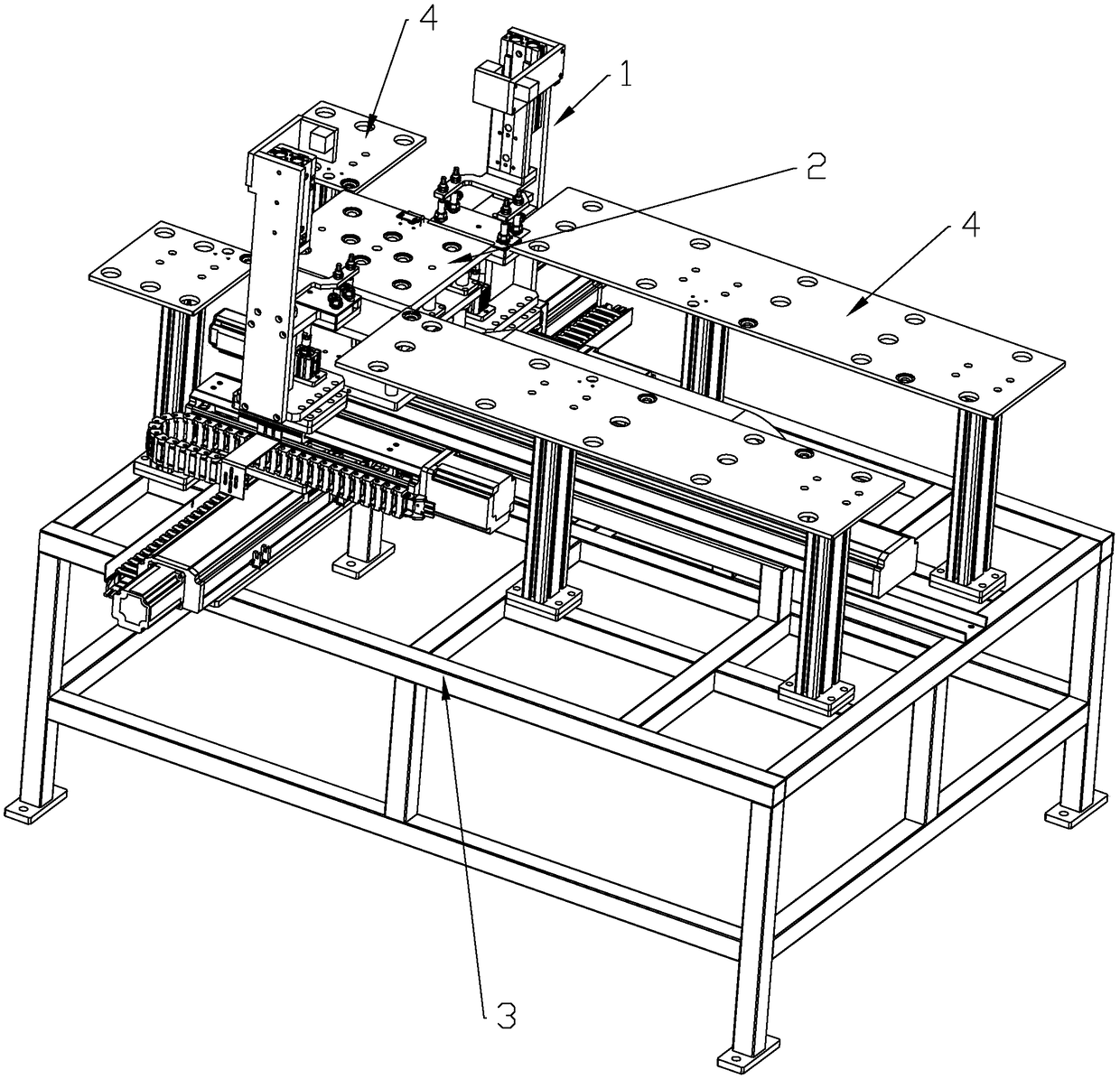

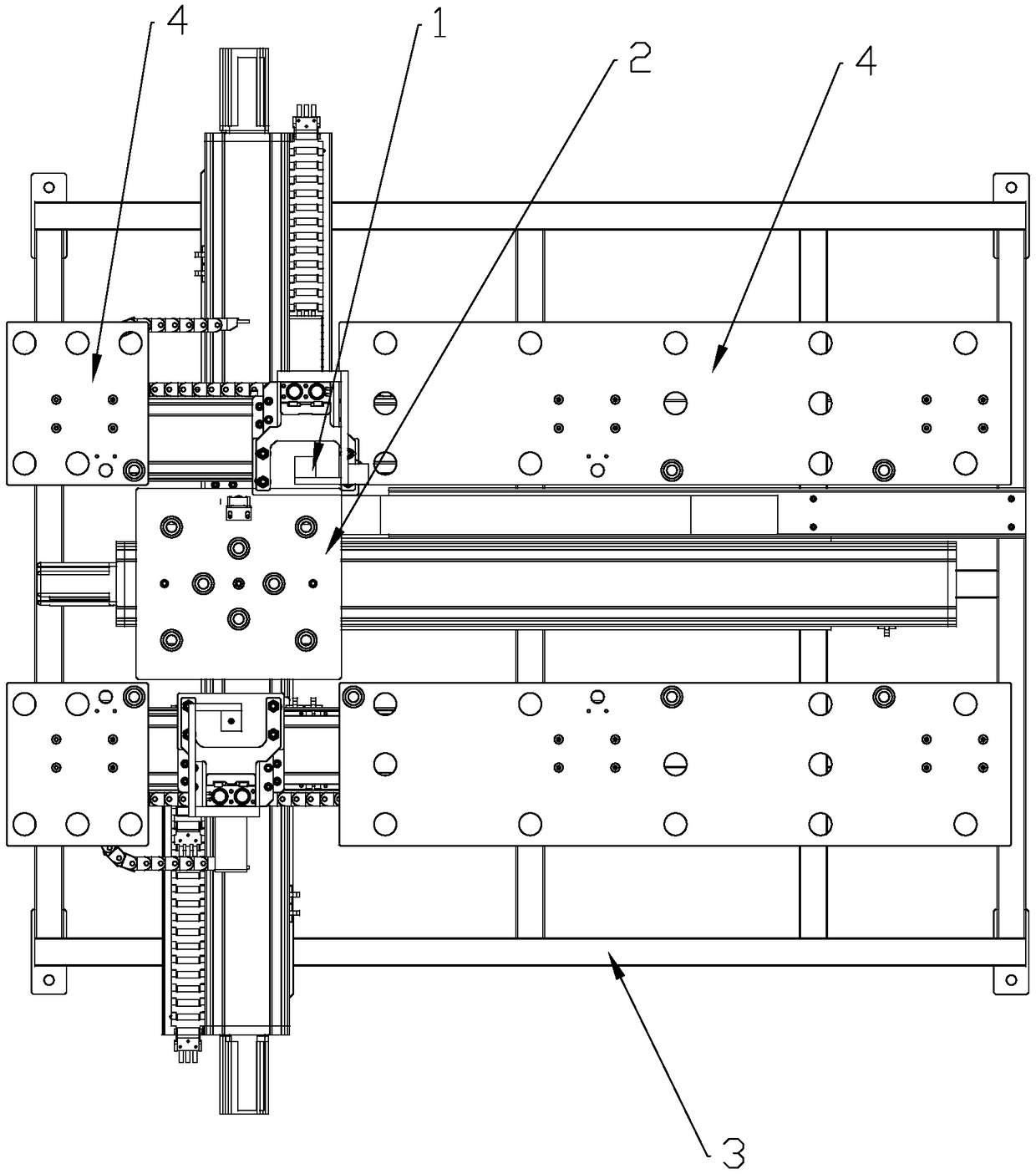

[0023] Refer to the attached figure 1 to attach Image 6 The CCD visual positioning device of the present invention will be described in detail below.

[0024] CCD visual positioning device of the present invention, its structure comprises copper plate vision system 1, copper plate transplanting mechanism 2, positioning support frame 3 and fixed support plate 4, described copper plate vision system 1, copper plate transplanting mechanism 2 and fixed support plate 4 They are arranged on the positioning support frame 3 respectively, and the copper plate vision system 1 and the fixed support plate 4 are respectively arranged on the outside of the copper plate transplanting mechanism 2 .

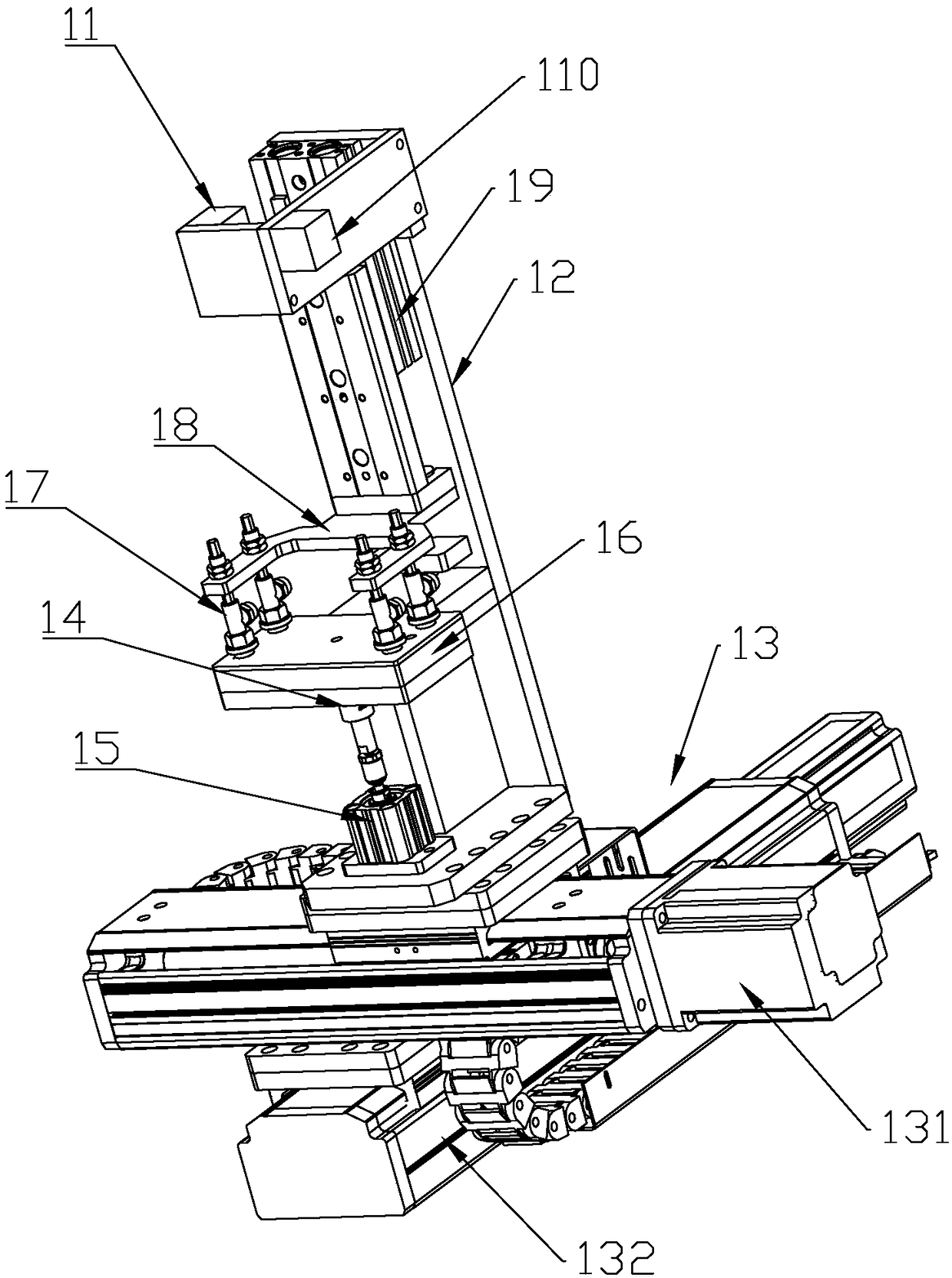

[0025] The copper plate vision system 1 is divided into left and right two, and each copper plate vision system 1 includes a pin hole positioning vision 11, a vision system fixing frame 12, a vision mobile drive module 13, a copper plate positioning pin 14, and a copper plate positioning pin dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com