Automatic discharging and stacking device for PCBs

An automatic unloading and palletizing device technology, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve problems such as unstable quality, high labor costs, scratches on the surface of PCB boards, etc., to avoid Unstable surface quality, avoiding long waiting time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

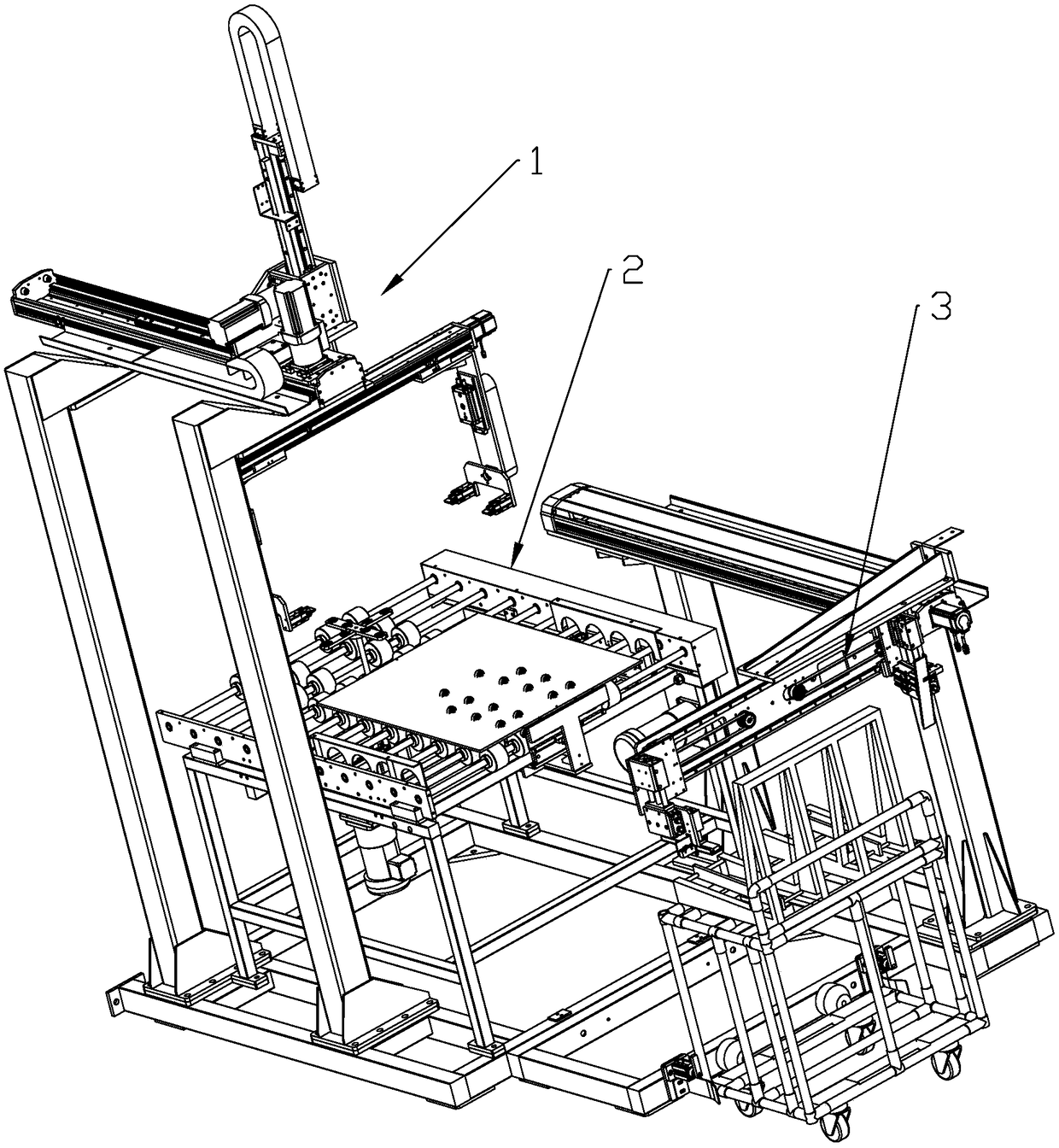

[0049] Refer to the attached figure 1 to attach Figure 14 The automatic unloading and palletizing device for PCB boards of the present invention will be described in detail below.

[0050] The structure of the automatic unloading and stacking device for PCB boards of the present invention includes a blanking clamping flip truss manipulator 1, a blanking conveying mechanism 2 and a flipping stacking device 3, and the blanking clamping flip truss manipulator 1 is arranged on the blanking On the front side of the conveying mechanism 2, the turning and stacking device 3 is arranged on the rear side of the unloading conveying mechanism 2.

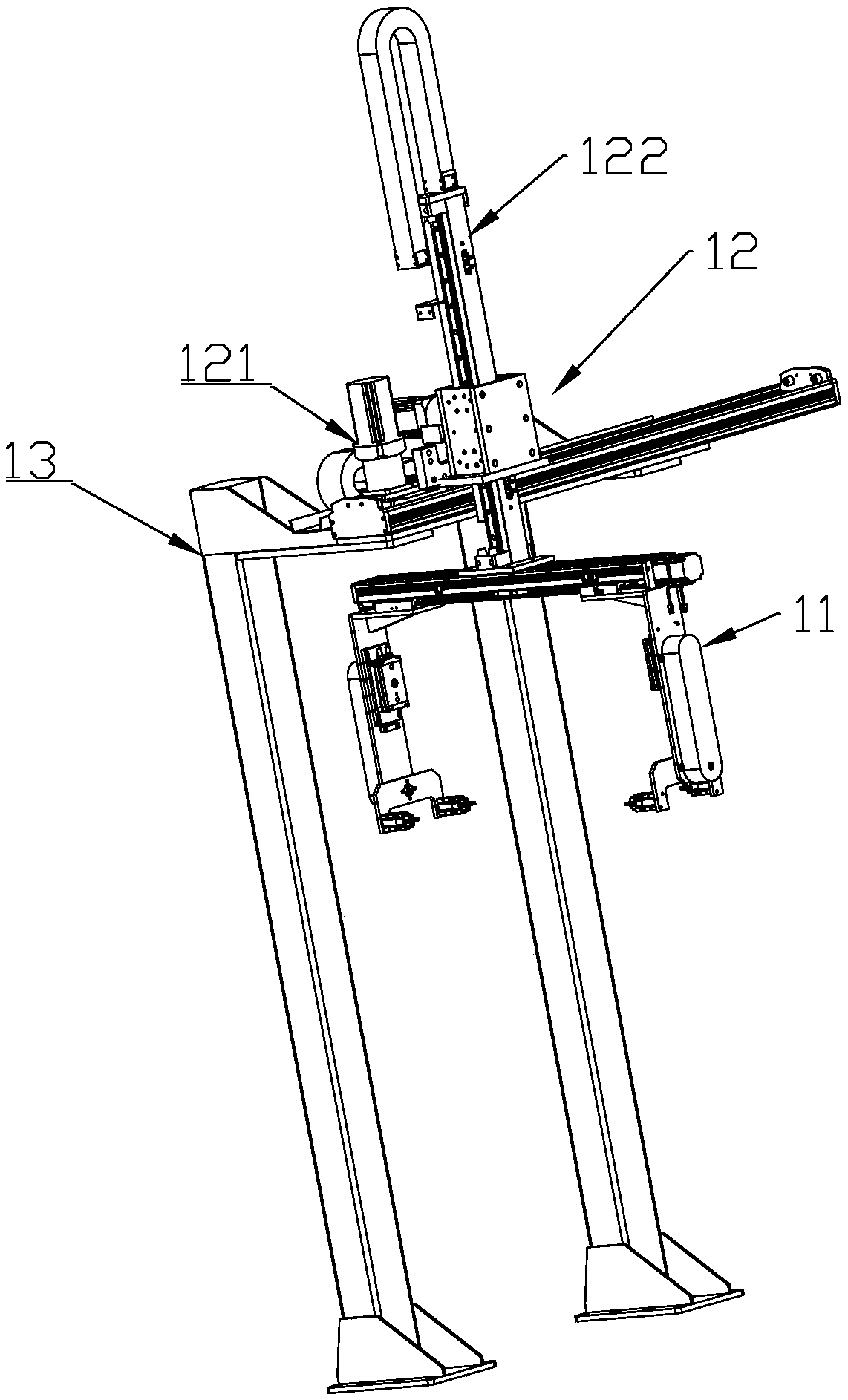

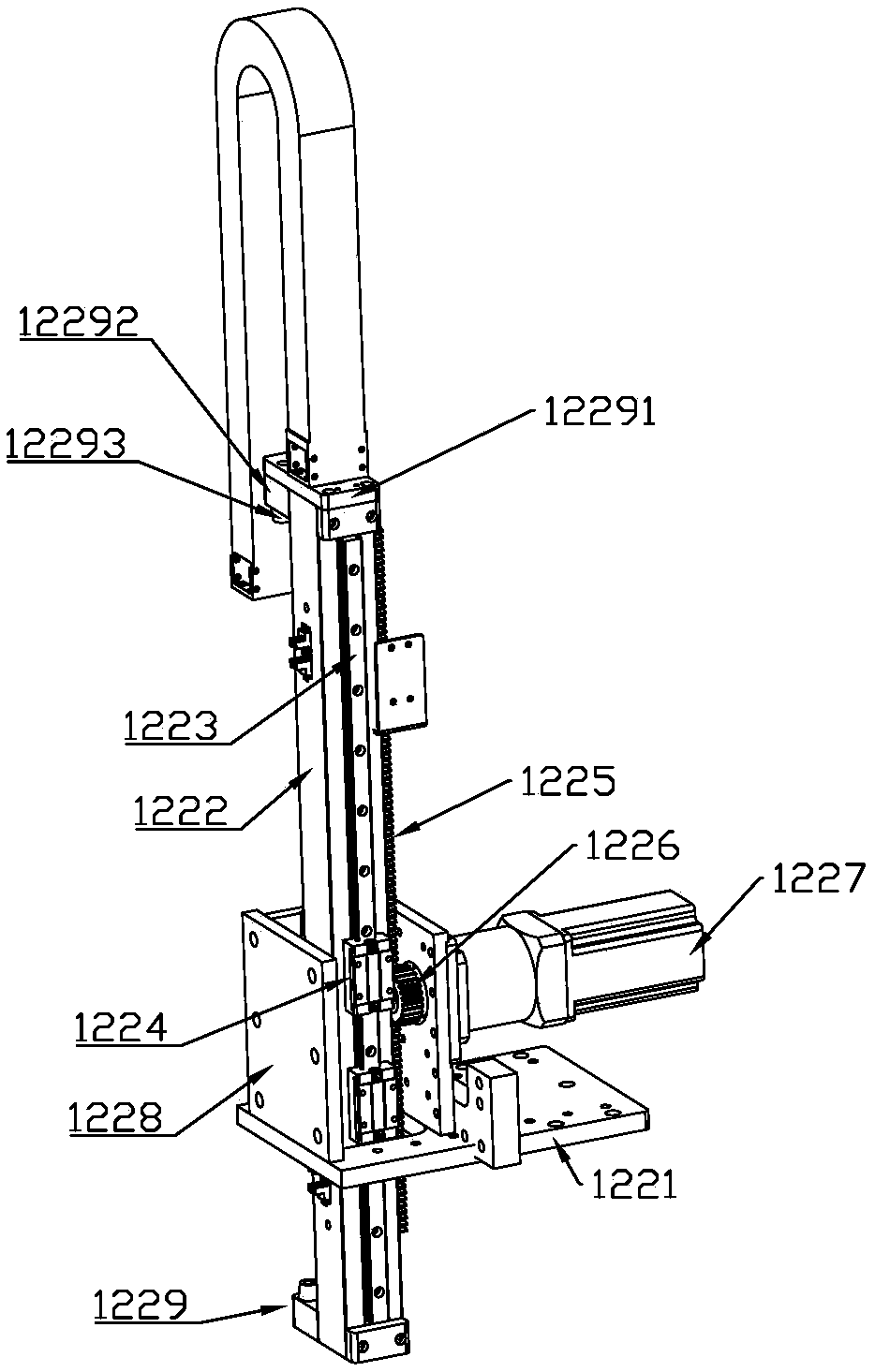

[0051] The described blanking and clamping flip truss manipulator 1 includes a blanking and clamping flipping manipulator 11, a blanking and clamping flipping manipulator moving drive mechanism 12 and a blanking and clamping flipping truss 13, and the blanking and clamping flipping manipulator 11 and The moving and driving mechanism 12 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com