Hard material automatic stringing machine

An automatic threading and stringing machine technology, applied in slaughtering, meat processing equipment, food science, etc., can solve the problems of low hardness and strength of bamboo sticks, inability to pierce hard materials, and inability to thread strings of hard materials, etc., to improve quality products High efficiency, guaranteed appearance, and the effect of avoiding falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

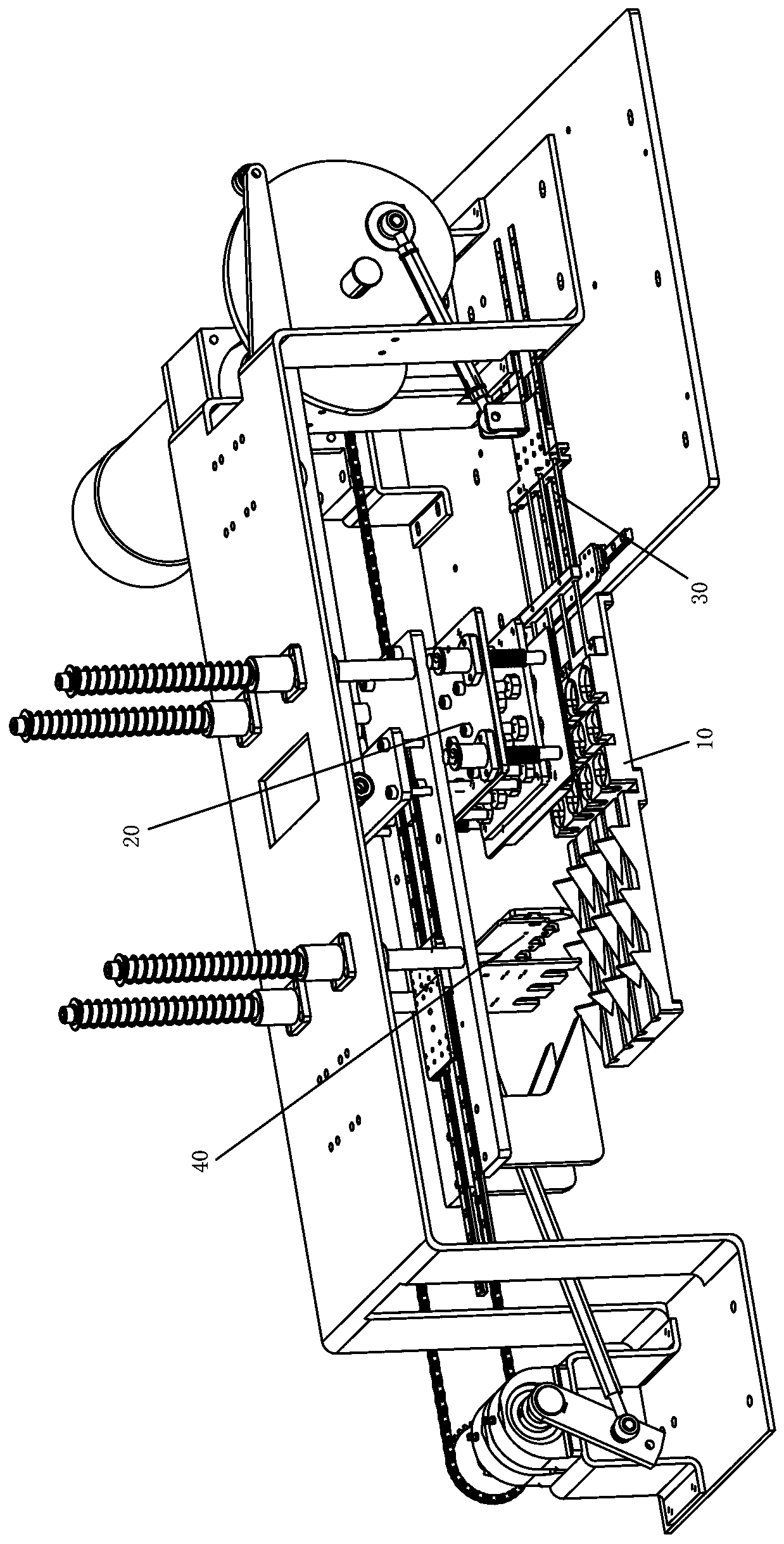

[0026] Such as figure 1 As shown, the embodiment provided by the present invention is a hard material automatic threading machine, including a loading mold 10, a pressing mechanism 20 is arranged above the loading mold 10, a piercing mechanism 30 is arranged on the right side, and a piercing mechanism 30 is arranged on the left side. A lottery pushing mechanism 40 is arranged.

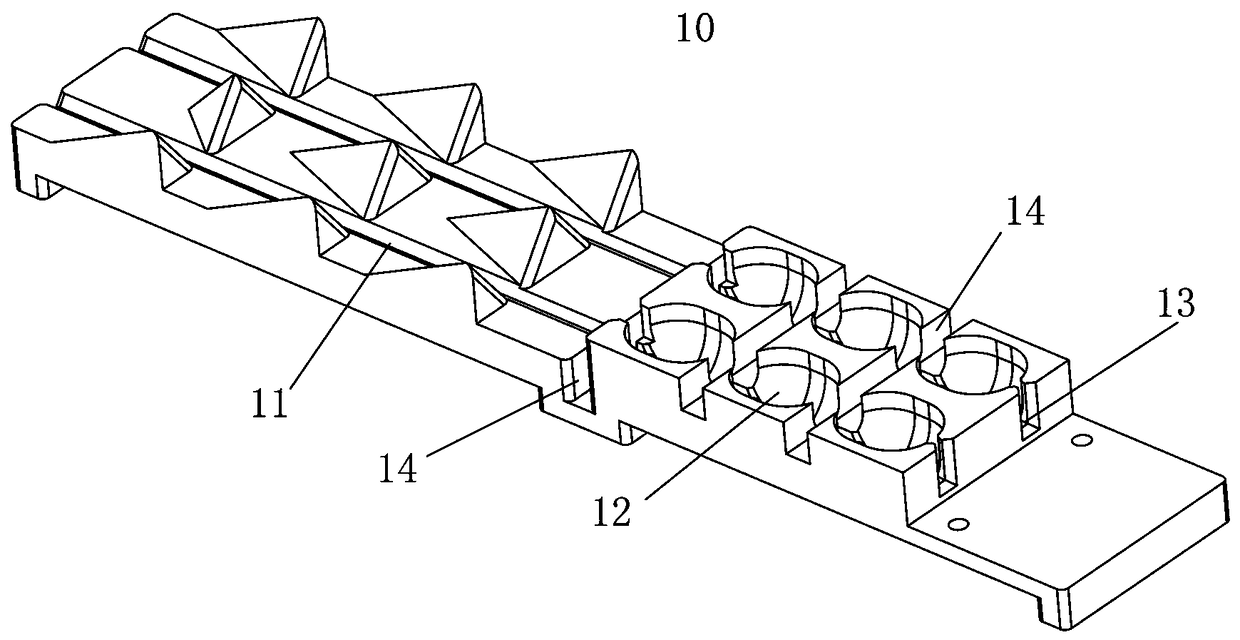

[0027] Such as figure 2 As shown, the upper surface of the loading mold 10 is provided with a signing groove 11 and at least one material groove 12 on the left and right. The material groove 12 is provided with a stabbing groove 13, and the stabbing groove 13 and the signing groove 11 are on the same axis. In this embodiment, there are three troughs 12 .

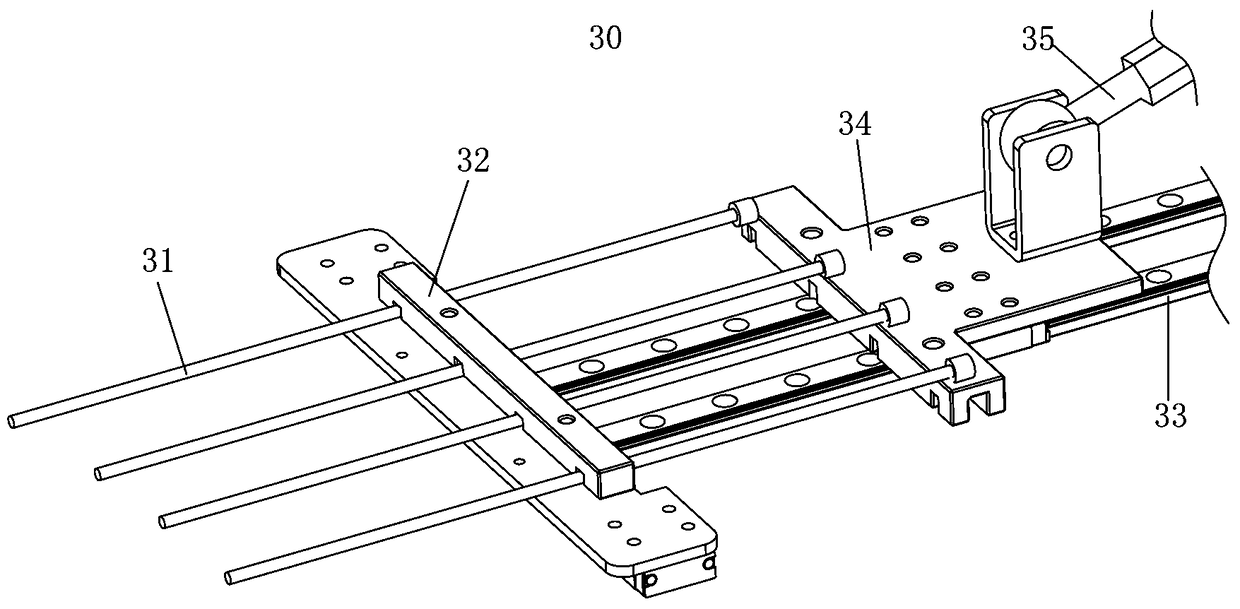

[0028] Such as image 3 As s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap