Cold-rolled steel plate polishing equipment applied to manufacturing of high-end equipment

A technology of cold-rolled steel plate and equipment, applied in the field of cold-rolled steel plate polishing equipment, can solve the problems of inability to polish the cold-rolled steel plate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

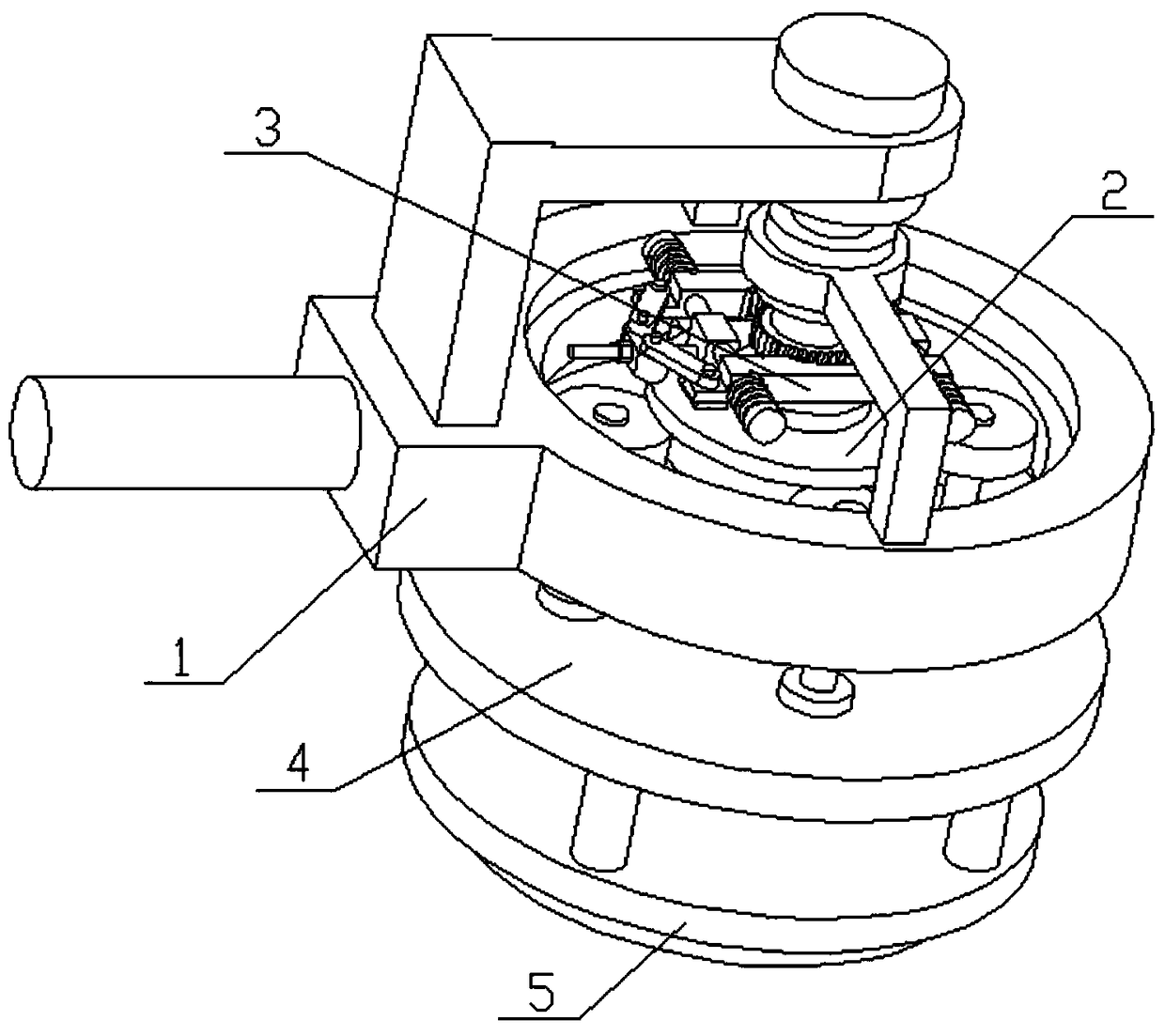

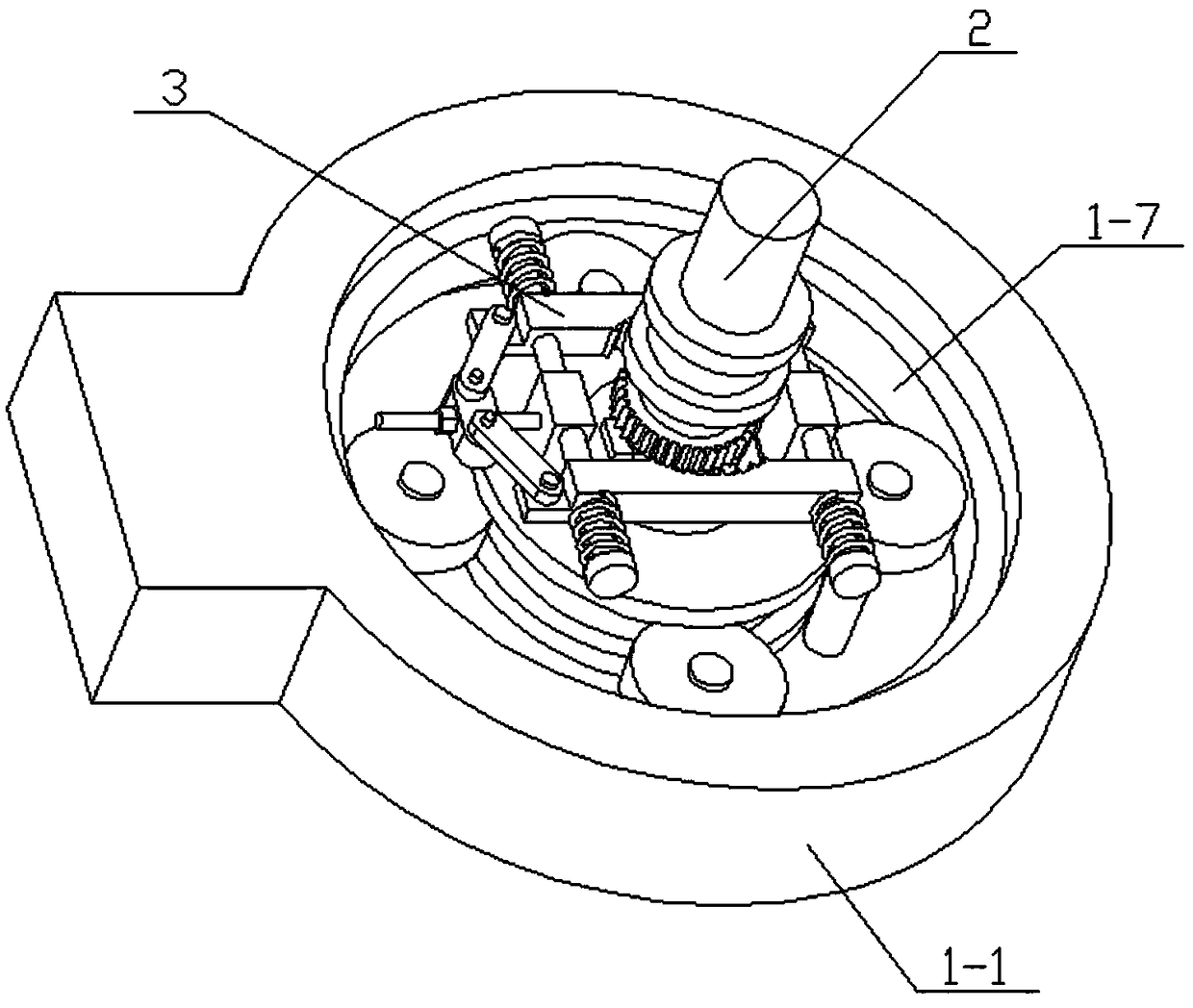

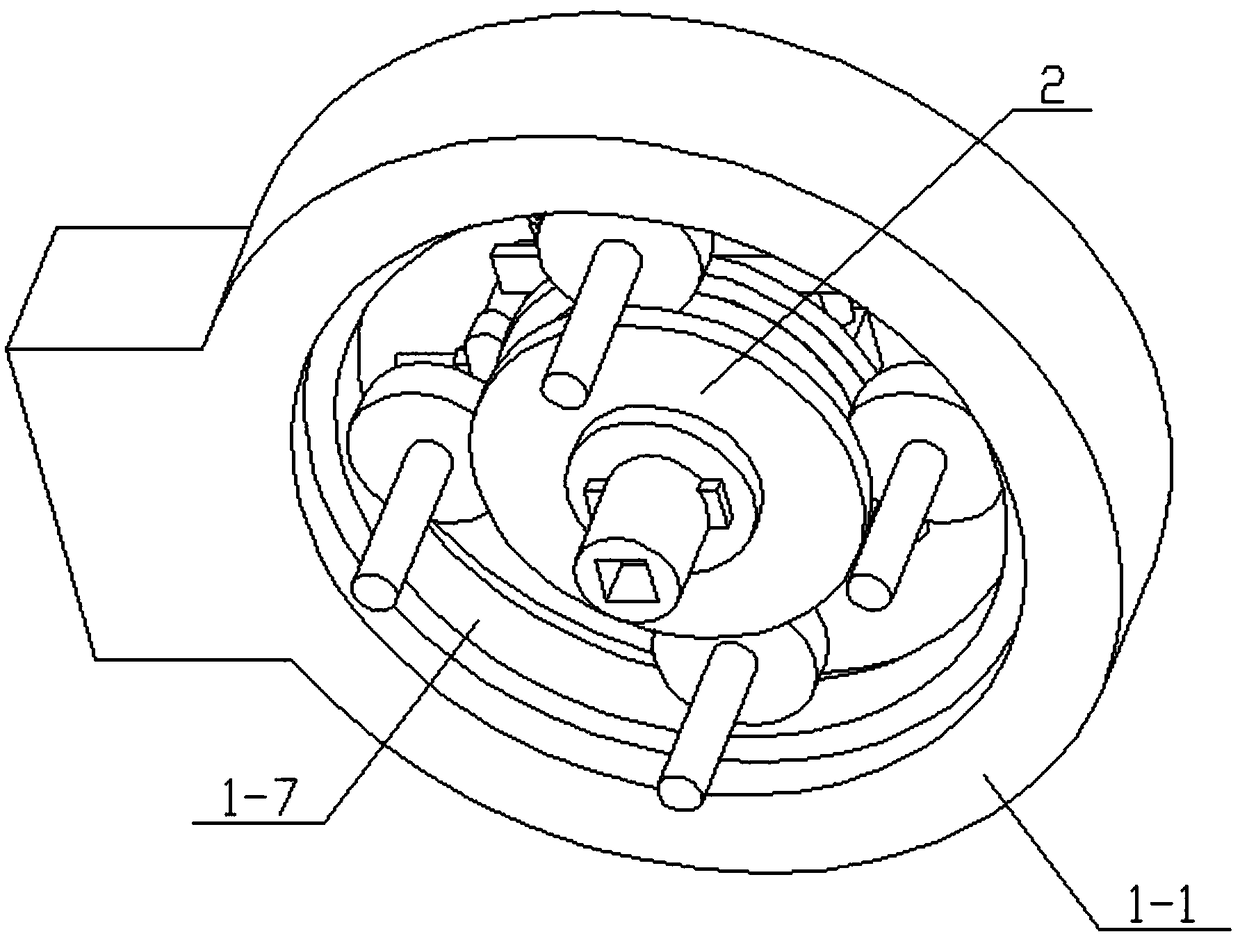

[0030] Combine below Figure 1-13 To illustrate this embodiment, the present invention relates to the field of high-end equipment manufacturing, more specifically, a cold-rolled steel plate polishing equipment for high-end equipment manufacturing, including a handheld frame 1, a main shaft 2, a clutch frame 3, a planetary rotating member 4 and The polishing disc 5 can be selected to drive the fixed gear 2-2 to rotate through the shaft rod 2-1 in the present invention, and the fixed gear 2-2 drives the four planetary gears 4-4 to rotate to realize the circular tray 4-1 and the rotating disc 5-1 deceleration rotation; can also directly drive the rotation mode of the circular tray 4-1 and the rotating disk 5-1 through the shaft rod 2-1, so as to realize the relatively high-speed rotation of the circular tray 4-1 and the rotating disk 5-1; the rotating disk can be 5-1 Adjust to low speed or high speed to adapt to different polishing needs.

[0031] The handheld frame 1 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com