Rubber and plastic product continuous production system and production method

A technology for rubber and plastic products and production systems, applied in the field of rubber and plastic products processing, can solve the problems of low intelligence of production lines and no intelligent continuous production line scheme, and achieve the effects of rich product types, saving labor costs and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

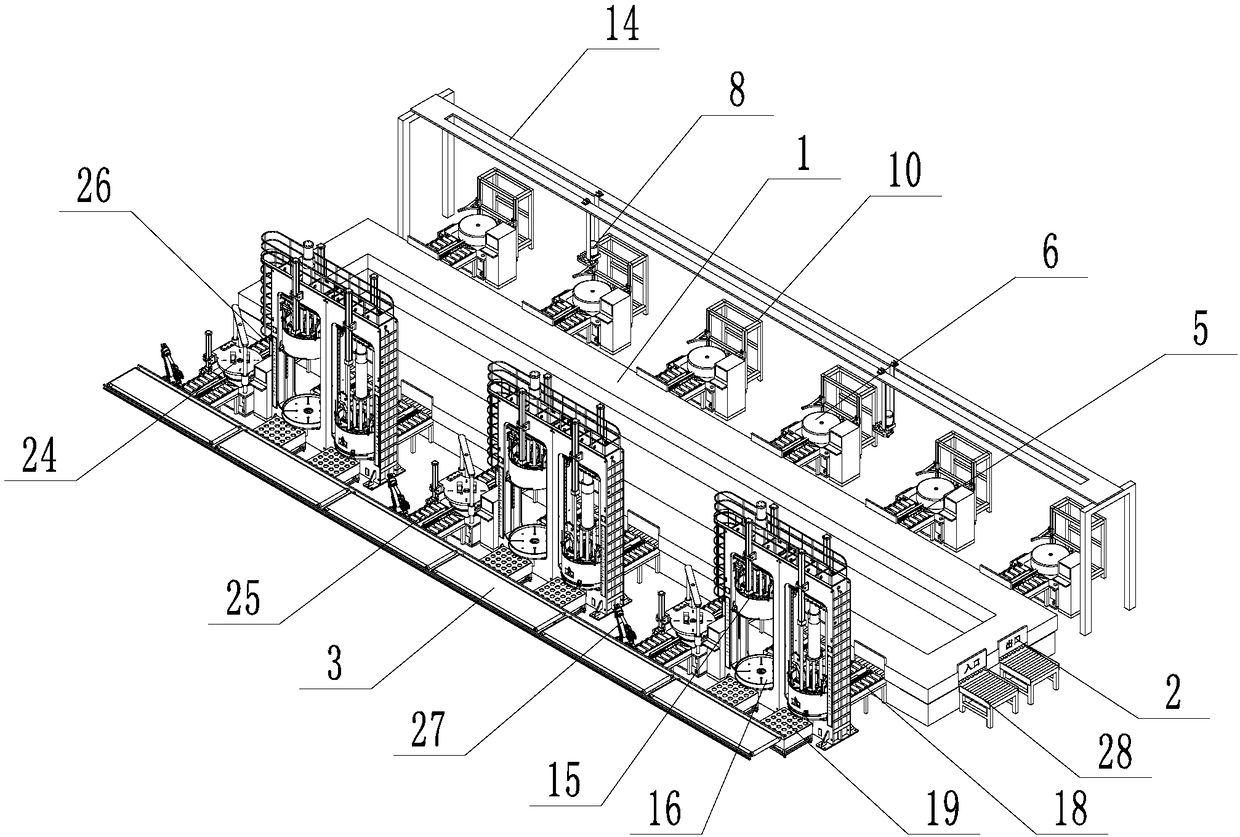

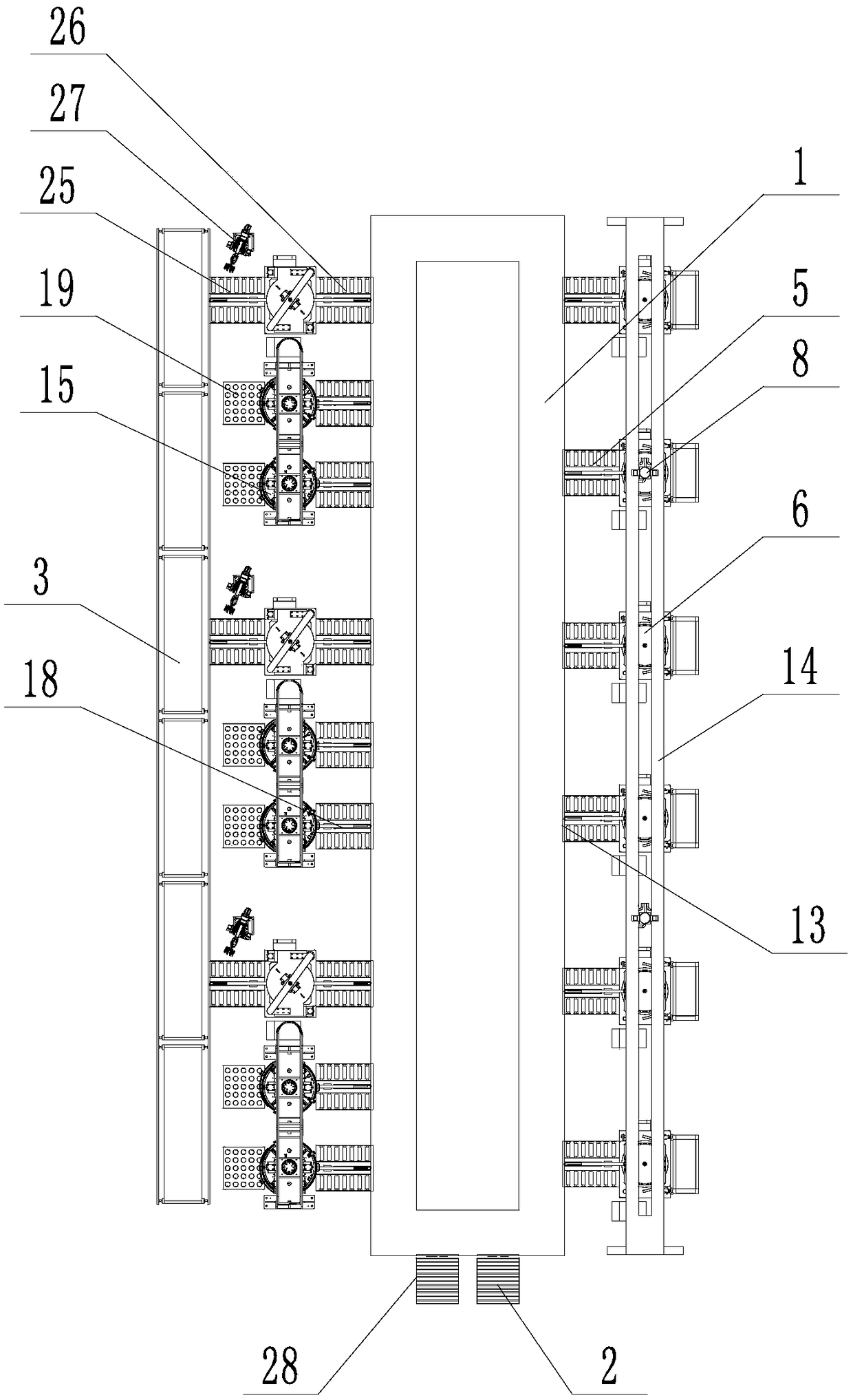

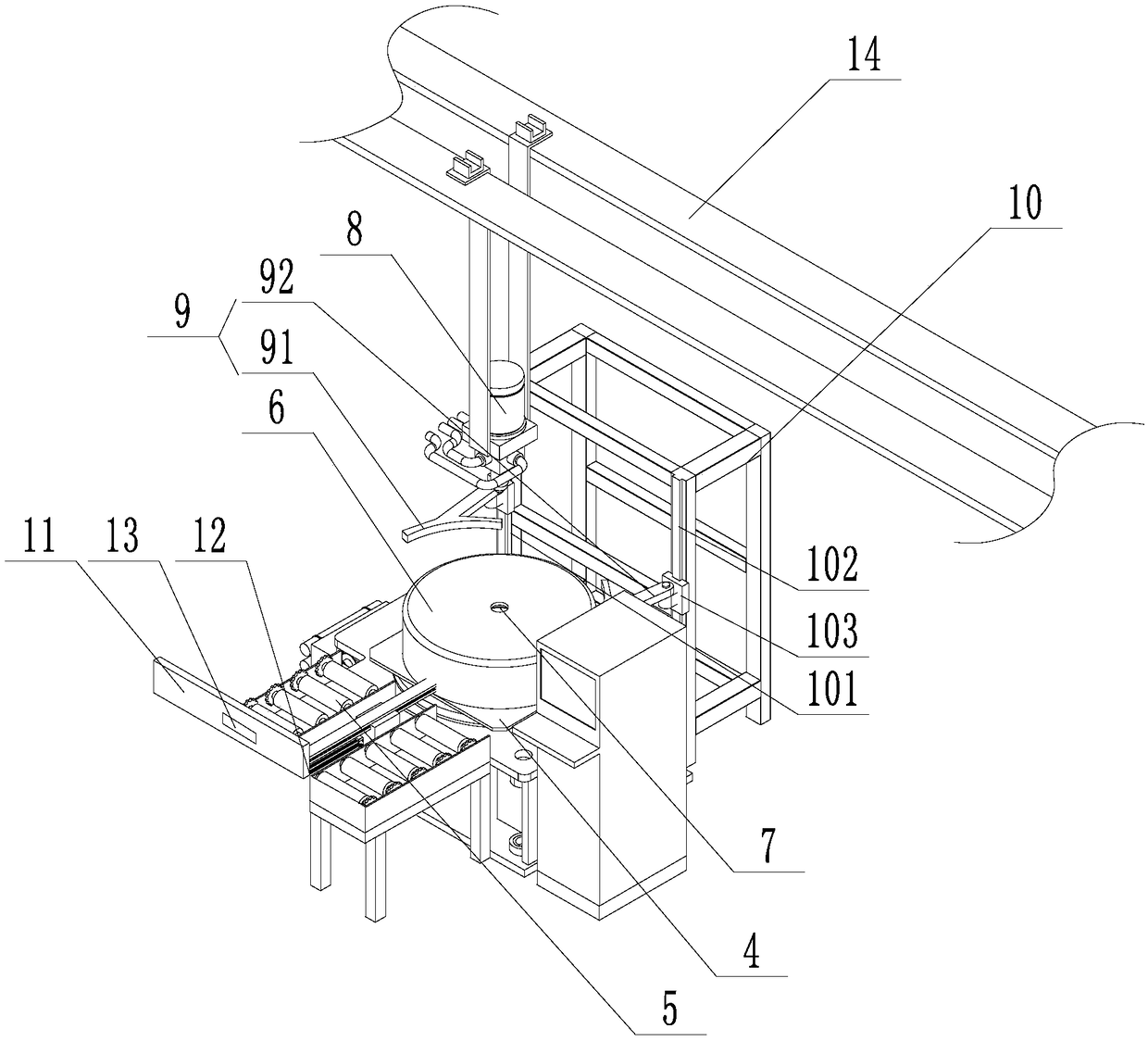

[0043] Example: such as figure 1 , figure 2 As shown, the embodiment of the present invention provides a continuous production system for rubber and plastic products, including a thermal insulation conveying loop 1 for conveying empty moulds, which is arranged on the thermal insulation conveying loop 1 for conveying empty molds to the thermal insulation conveying loop 1 The mold feeding conveying door 2, the vacuum pouring device arranged on one side of the heat preservation conveying loop line 1, and the mold opening and closing device and vulcanization device arranged on the other side of the heat preservation conveying circle line 1, the mold opening and closing device A product conveying line 3 for conveying vulcanized rubber and plastic products is arranged on the side away from the insulation conveying loop 1 of the vulcanizing device.

[0044] The present invention provides a continuous production system for rubber and plastic products, in which the structural layout ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com