Printer negative pressure adsorption mechanism

A technology of adsorption mechanism and printer, applied in the direction of typewriter, printing, etc., can solve the problems of operator's physical impact, affecting printing effect, air pollution, etc., and achieve the effect of large adsorption space, improving printing efficiency, and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

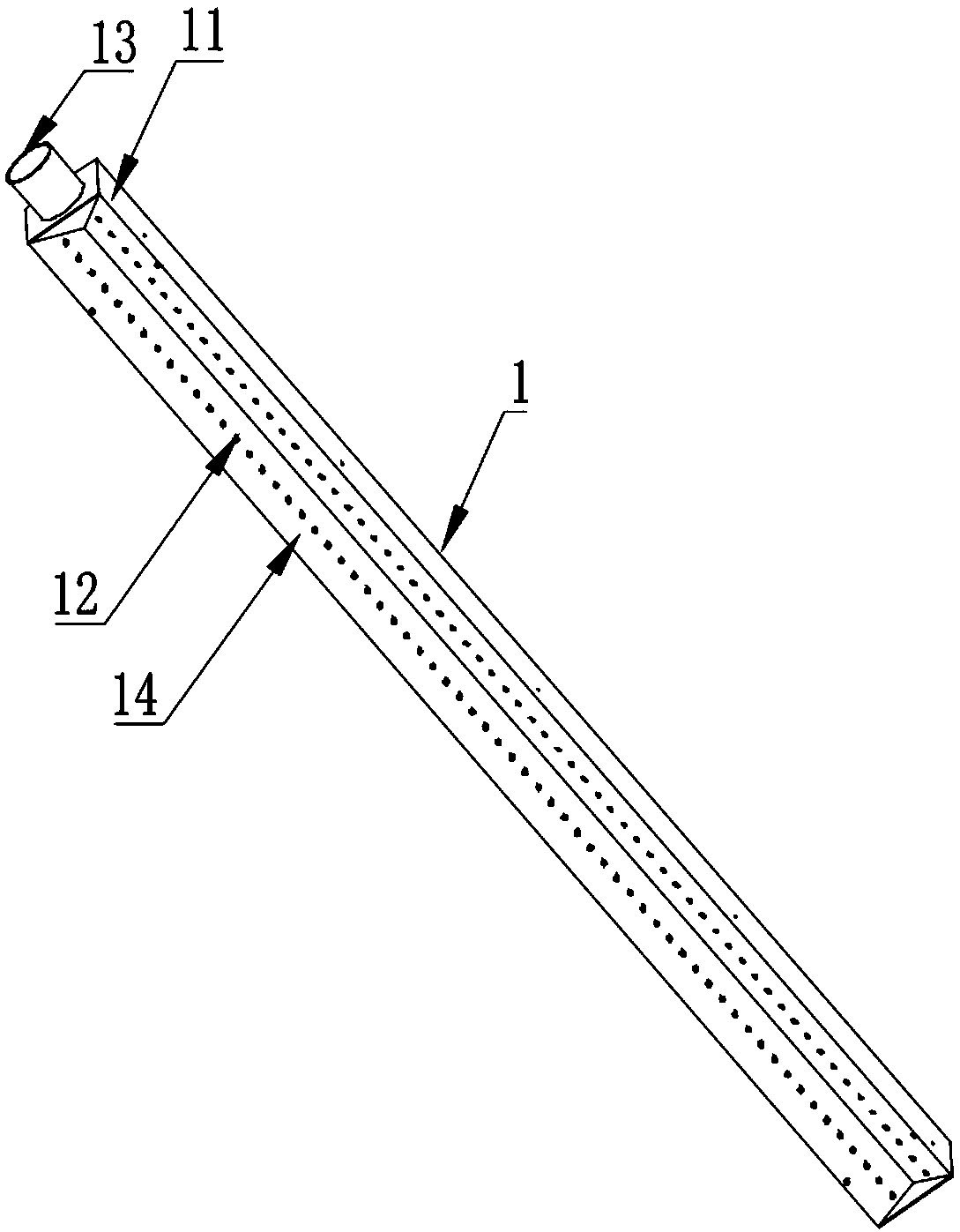

[0059] Such as figure 1 As shown, the present invention provides a printer negative pressure steam adsorption mechanism 1, which is installed on the printer and is used to absorb ink mist. The ink mist is the mist formed by water vapor and ink. The adsorption mechanism 1 has a tubular hollow structure. An adsorption channel 11 and an adsorption part 12 are provided. One end of the adsorption channel 11 is provided with an interface 13 connected to a negative pressure adsorption device. The adsorption part 12 is distributed on the lower side of the adsorption mechanism 1, and the middle part of the adsorption part 12 is concave. A plurality of adsorption holes 14 are distributed on the surface.

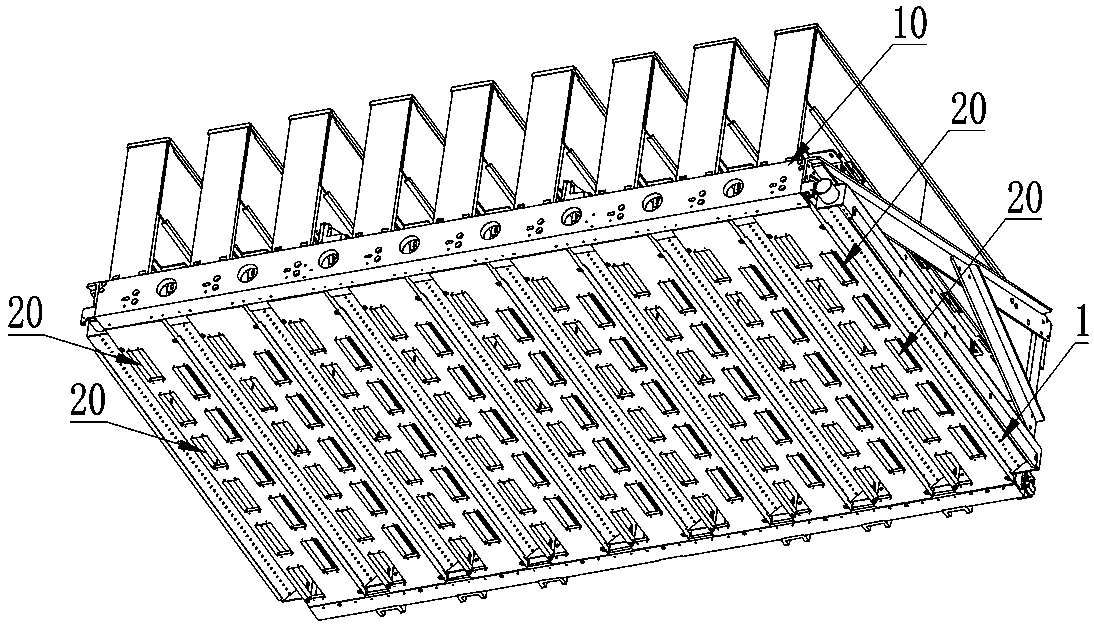

[0060] The printer of the present invention is mainly aimed at industrial printers, and can be used for printing on ceramic tiles, wood boards, glass, corrugated, PCB, textiles, metal plates and other media. Such as figure 2 As shown, the printer is provided with an inkjet bracket 1...

Embodiment 2

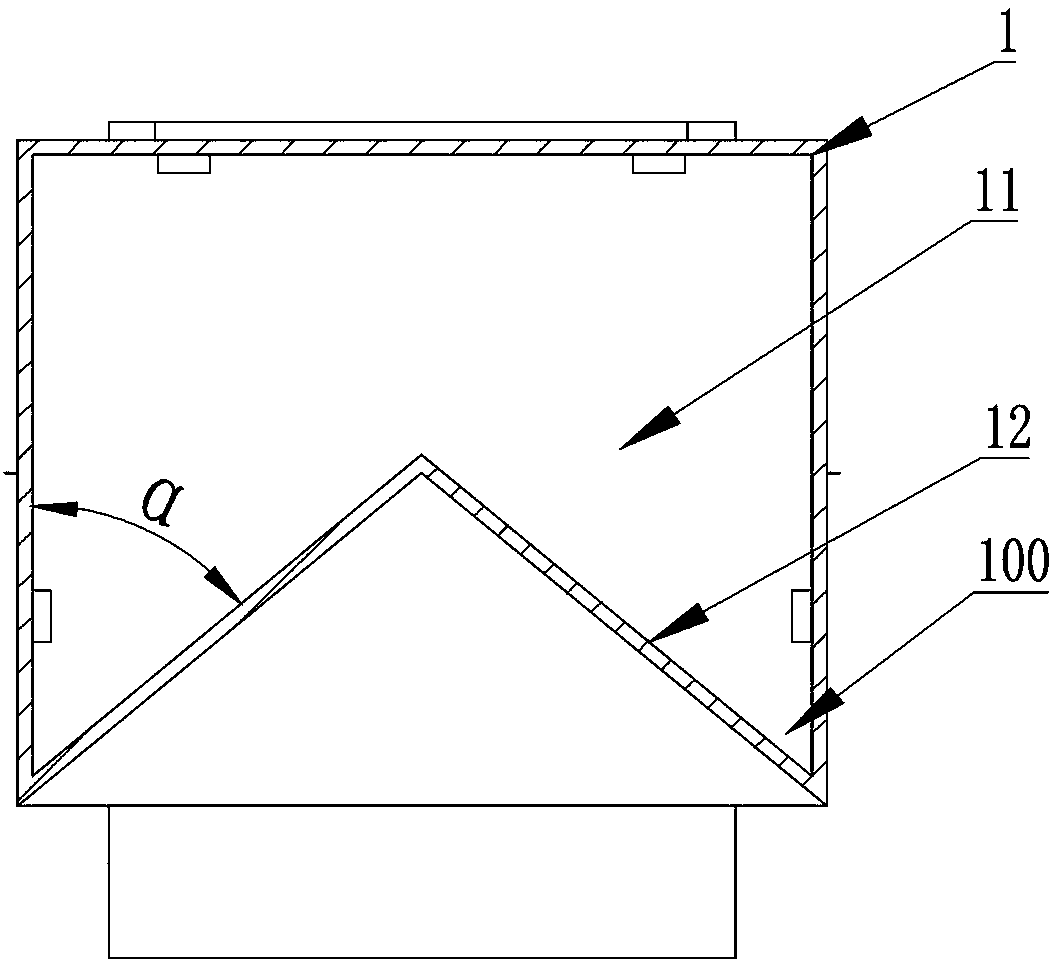

[0094] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the angle α formed by the inverted “V” shape formed by the adsorption portion 12 and the side wall of the adsorption channel 11 is 40°.

Embodiment 3

[0096] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the angle α formed by the inverted “V” shape formed by the adsorption portion 12 and the side wall of the adsorption channel 11 is 60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com