A kind of laying method of glass fiber reinforced flexible pipe

A laying method and flexible pipe technology, applied in the direction of pipe-laying ships, etc., can solve the problems of low safety and reliability of glass fiber reinforced flexible pipes, and achieve the effects of avoiding floating and instability, improving safety and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

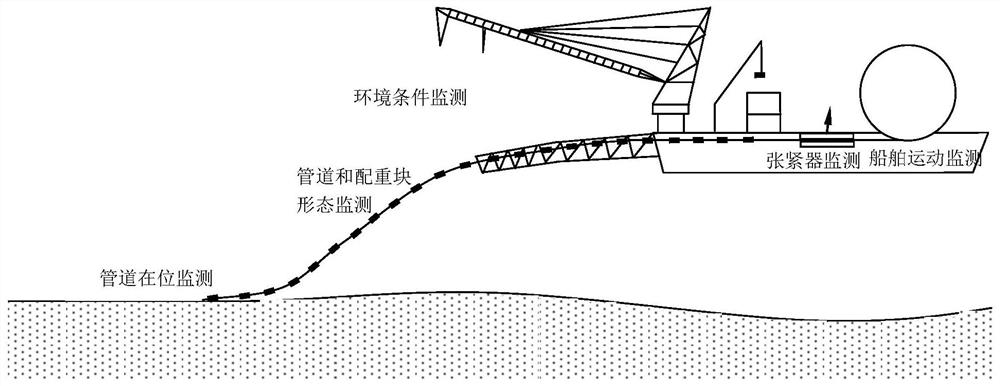

[0040] The embodiments of the present application provide a method for laying glass fiber reinforced flexible pipes, which solves the problem of low safety and reliability of laying glass fiber reinforced flexible pipes with counterweights in the prior art using the R-type pipe laying ship method , There are technical problems with greater risks.

[0041] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

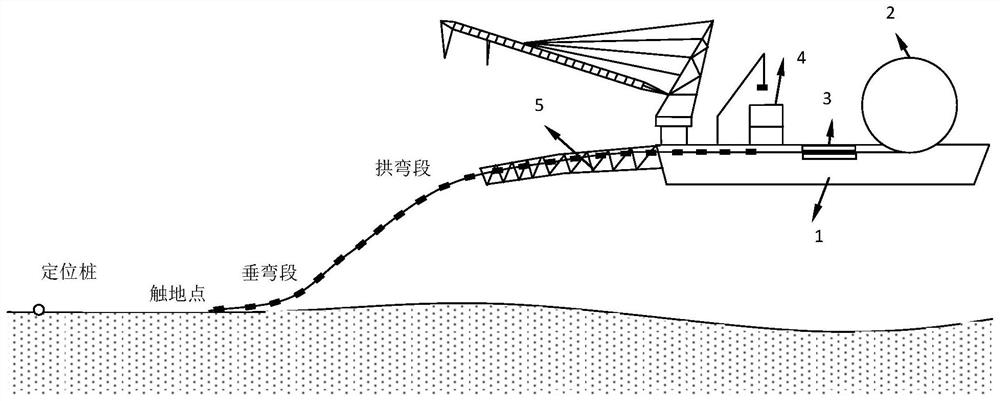

[0042] A method for laying glass fiber reinforced flexible pipes, which is applied on the pipe-laying ship, and the pipe-laying ship includes a drum, a tensioner, a counterweight installation device and a stinger; the tensioner is arranged horizontally and is located at Between the counterweight installation device and the drum, the stinger is arranged on the stern of the pipelaying vessel, and the method includes:

[0043] Transporting the glass fiber reinforced flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com