Electronic product automatic rail conveying mechanism

A technology of electronic products and conveying mechanisms, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of increasing labor costs, low efficiency, and investing a lot of human resources, so as to reduce labor intensity and production costs. The effect of liberating labor force and high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

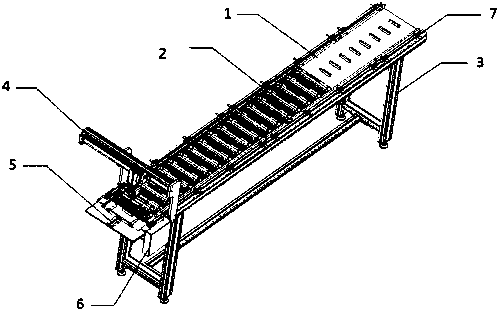

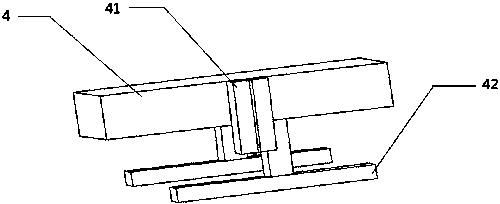

[0016] Example: such as Figure 1-2 As shown, the present invention provides an electronic product automatic track conveying mechanism, comprising a frame body 3, a rail conveyor belt 1 installed on the frame body 3, and an electronic product 2 conveyed by the rail conveyor belt 1; A motor unit that drives the track conveyor belt 1 to work is installed at the end; a pick-up part 4 is installed on the top of the start end of the track conveyor belt 1, and the pick-up part 4 includes a main frame and a mechanical clip 42 installed at the bottom of the main frame And drive the retrieving motor 41 of mechanical clip 42; This conveying mechanism also comprises the material-shifting photoelectric sensor 6 that is installed on the rail conveyor belt 1 starting end side and the material shortage sensor 7 at the rail conveyor belt 1 tail end; Two photoelectric sensors are positive For the electronic product 2. The mechanical clip 42 includes two opposing rods and a transmission device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com