Full-automatic welding wire layer winding machine

A layer winding machine, fully automatic technology, applied in the direction of conveying filament materials, thin material processing, transportation and packaging, etc., can solve the problems of high labor intensity, low work efficiency, low automation level of welding wire layer winding machine, etc., to achieve The effect of reducing production costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The method of the invention will be further described below in conjunction with the accompanying drawings and examples.

[0040] In order to describe the relative position of each part and the moving direction of each moving part more clearly, three directions X, Y, and Z are defined to construct a rectangular coordinate system, where the X direction indicates the direction along the axis of the main shaft to the tailstock, and the Y direction indicates Parallel to the plane of the workbench, perpendicular to the X direction and pointing to the side of the wire reel discharge slot, and the Z direction is perpendicular to the plane of the workbench and facing upwards.

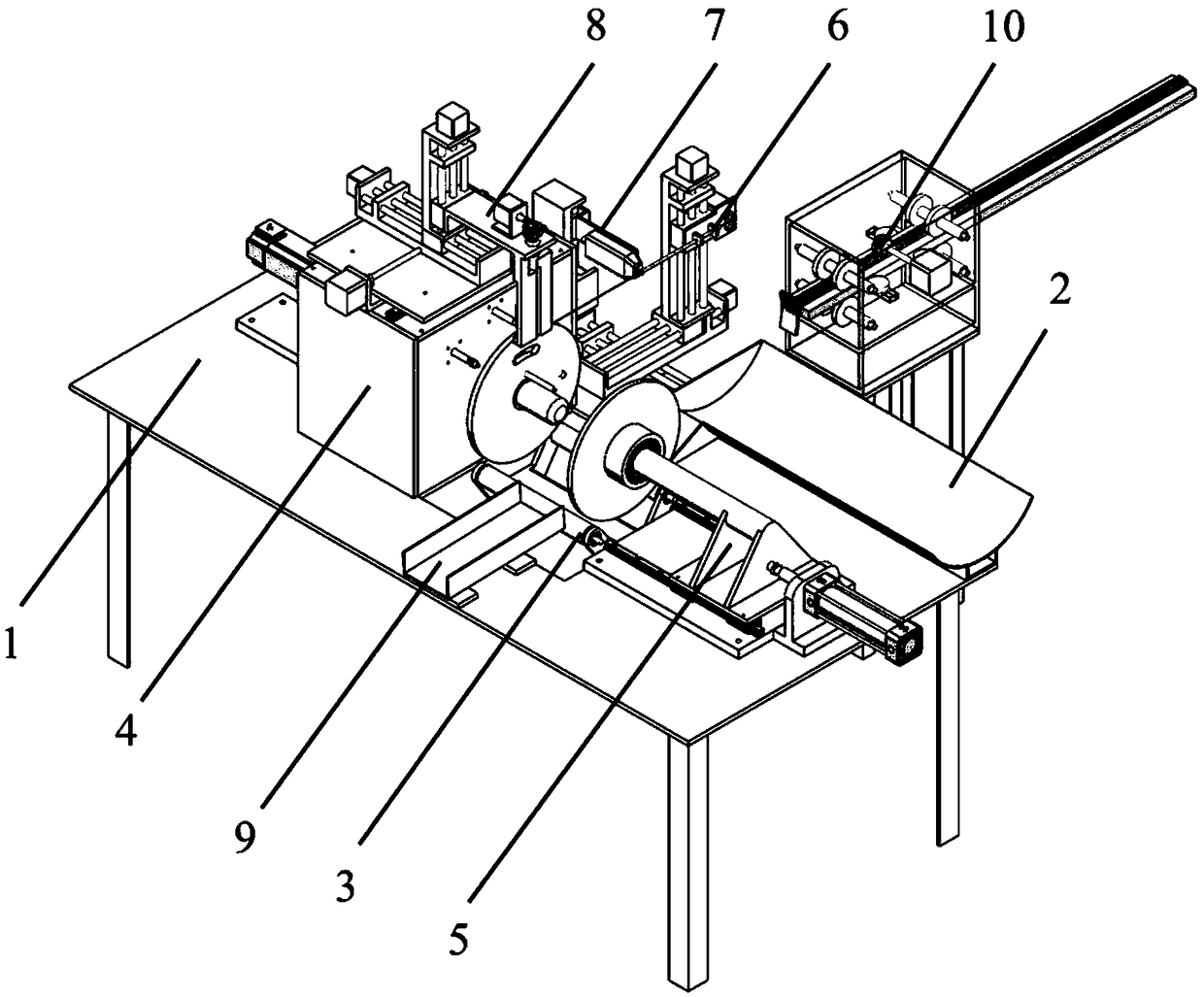

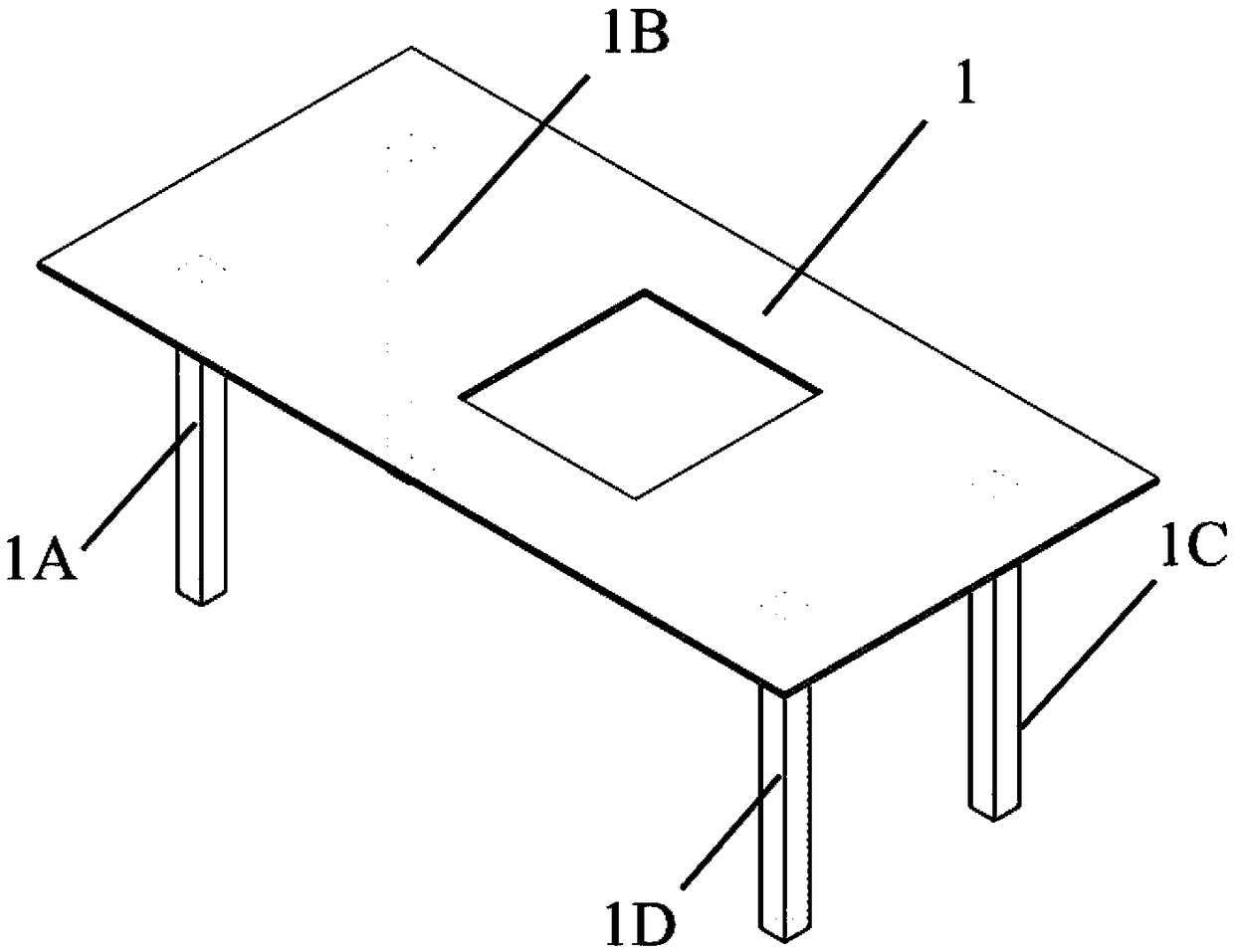

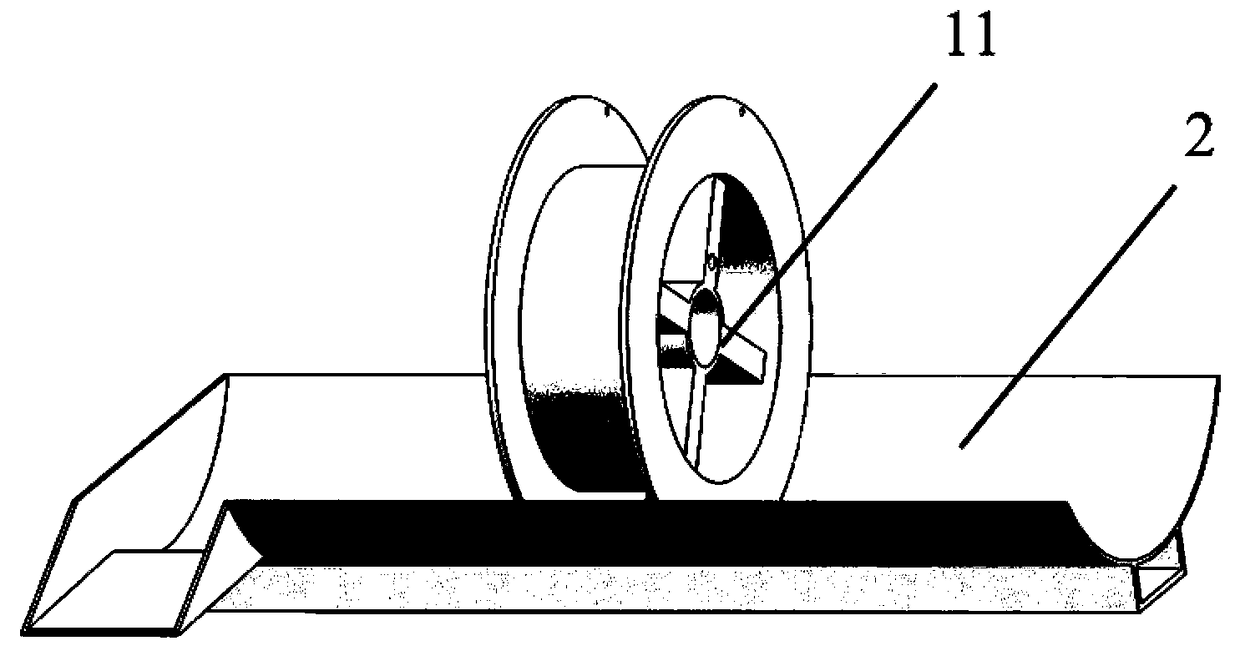

[0041] A kind of fully automatic welding wire layer winding machine proposed by the present invention, a kind of implementation example thereof is figure 1 As shown, in this example, the wire reel feeding chute 2, the main shaft part 4, the tailstock part 5, the wire feeding part 6, and the wire reel outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com