Shaft guide connecting device and connecting method thereof

一种连接装置、连接方法的技术,应用在竖井装备、土方钻采、运输和包装等方向,能够解决罐道安装精度低、上下罐道挤压易变形、不方便罐道维护、调整、更换等问题,达到方便更换罐道、加强牢固性和稳定性、加强稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

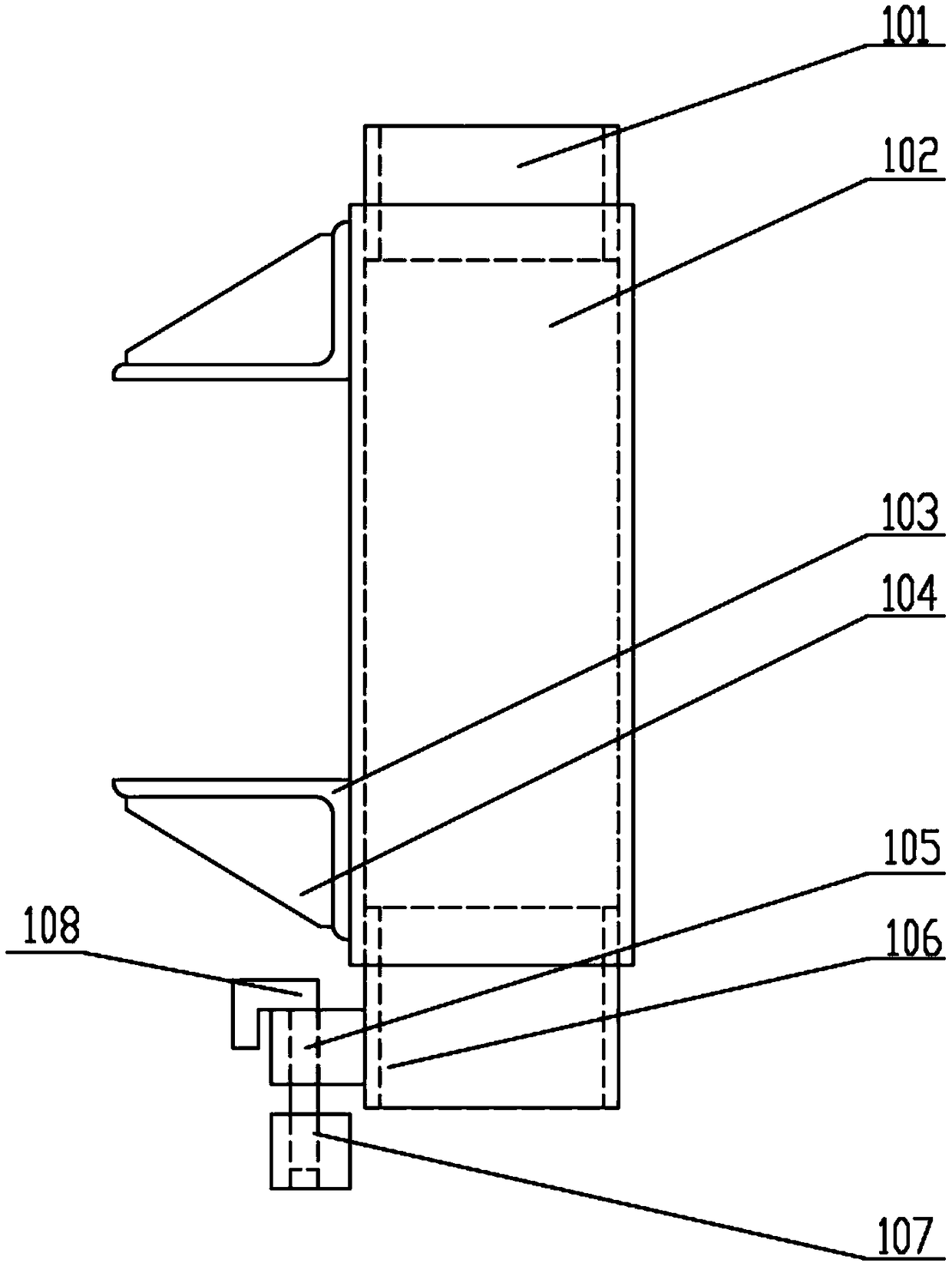

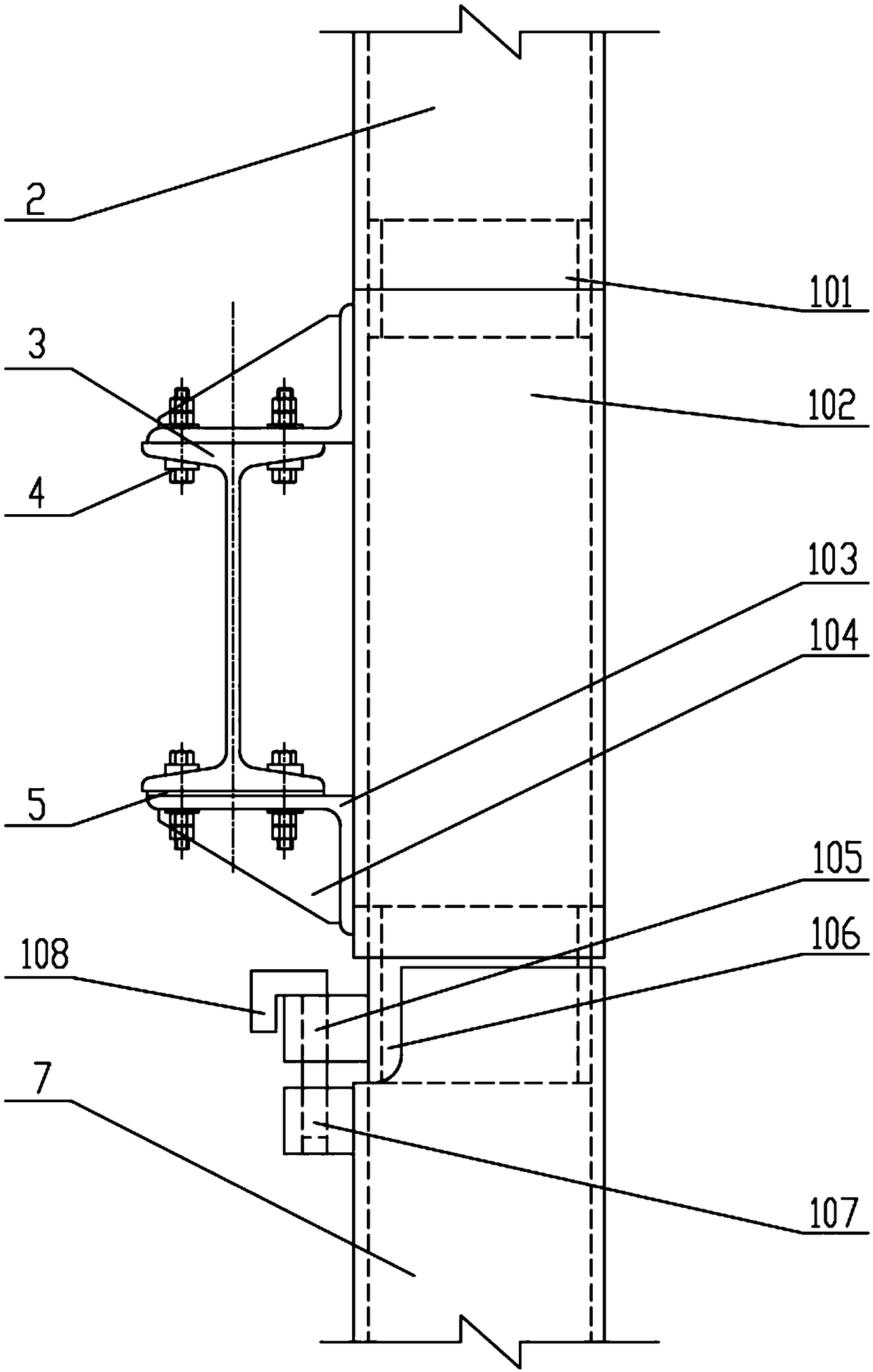

[0053] see figure 1 as well as figure 2 In this embodiment, the tank connecting device is arranged between two tanks. In this embodiment, for the convenience of description, these two tanks are named upper tank 2 and lower tank 7, and the tank connecting device connects Upper tank road 2 and lower tank road 7. Wherein, one side of the top of the lower tank passage 7 offers a gap. In this embodiment, the tank road connecting device includes a connecting tank 102 , an upper tongue tube 101 , a lower tongue tube 106 , two angle steels 103 , a fixing block 105 , a pin seat 107 , a fixing pin 108 , and two ribs 104 . Wherein, the tank road connecting device is separated separately, that is, the guiding function and positioning function of the traditional tank road are respectively undertaken by each tank road and each corresponding tank road connecting device in this embodiment.

[0054] The connecting tank 102 is arranged between the upper tank road 2 and the lower tank road 7...

Embodiment 2

[0072] This embodiment provides a method for connecting a tank road connecting device, and the tank road connecting device adopts the tank road connecting device in Embodiment 1. The connection method of the tank road connection device in this embodiment includes:

[0073] (a) Pre-assemble each tank road connection device and corresponding tank roads at the ground processing site, mark them, protect the ends of the tank roads, and wait for installation.

[0074] (b) Clamp the two angle steels 103 of each tank road connection device to the corresponding tank road beam 1 3, so that multiple tank road connection devices are respectively fixed on the corresponding tank road beam 1 3, and multiple tank roads are completed Fixing of the road connection device.

[0075] (c) Select the method of installation from bottom to top, put the top of the lower tank channel 7 on the bottom end of the lower tongue tube 106 of a corresponding tank channel connecting device, rotate the lower tan...

Embodiment 3

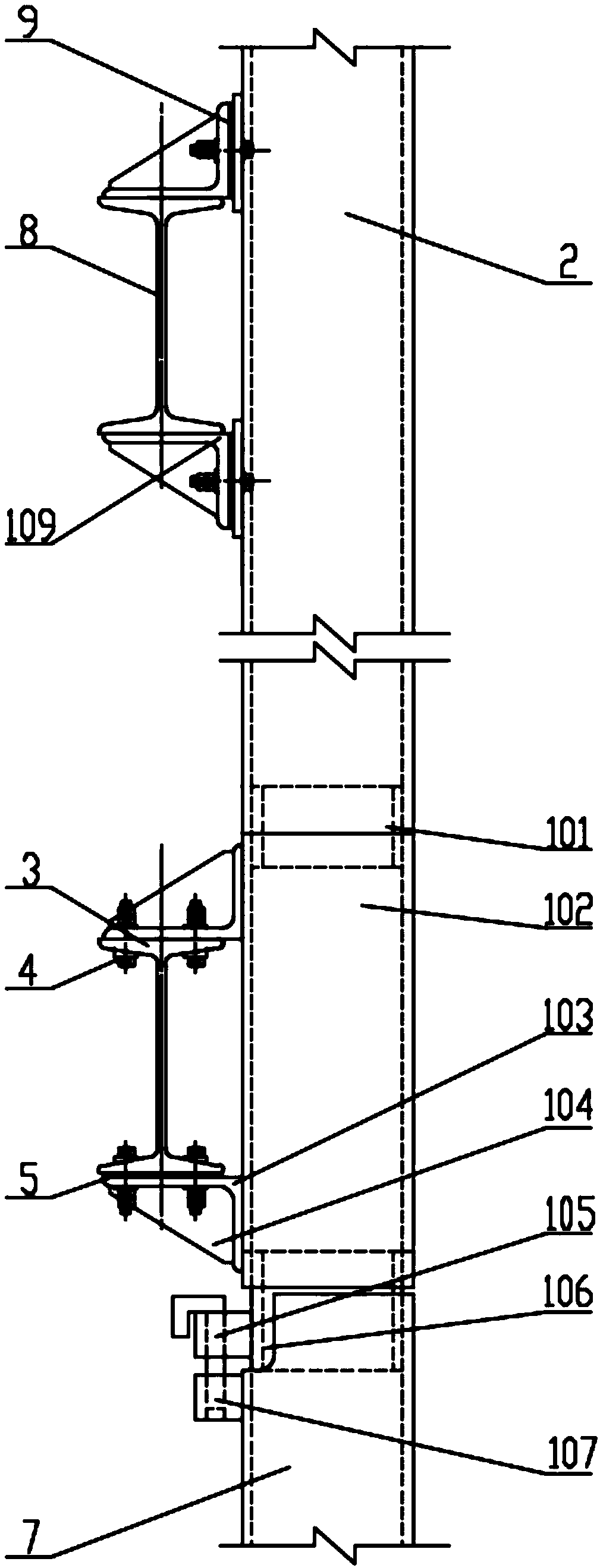

[0078] see image 3 as well as Figure 4 , on the basis of Embodiment 1, the tank road connection device of this embodiment adds an auxiliary mechanism. The auxiliary mechanism includes two symmetrically arranged two pieces of angle steel 109 and two backing plates 9 corresponding to the two pieces of angle steel two 109, wherein the two pieces of angle steel two 109 are all fixed on the same side of the upper tank road 2 or the lower tank road 7 And set from top to bottom. A tank road beam 2 8 is arranged between the two angle steel 2 109, and the two angle steel 2 109 are fixed on the top and the bottom of the tank road beam 2 8 respectively. Each backing plate 9 is arranged between a corresponding piece of angle steel 2 109 and the upper tank road 2 or the lower tank road 7 . In this embodiment, a rib plate 104 is also fixed on the bending surface of the second angle steel 109, so as to improve the stability of the second angle steel 109 under stress and improve the firm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com