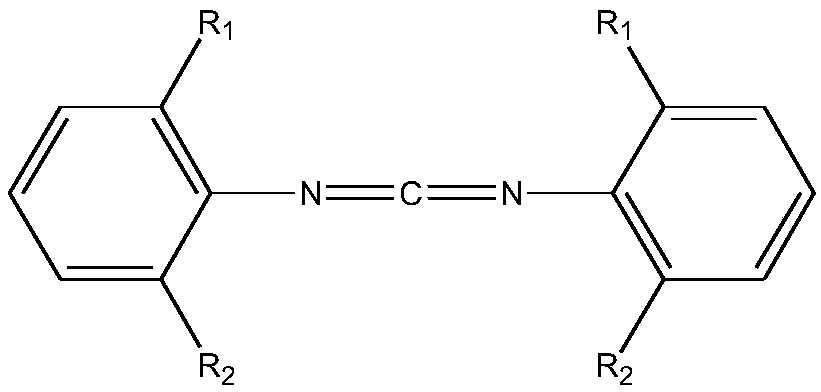

Preparation method and application of liquid carbodiimide compound

A technology for carbodiimide and compound, which is applied in the field of carbodiimide compound preparation, can solve problems such as limited application fields, achieve excellent heat aging resistance and weather resistance, and is beneficial to long-term storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

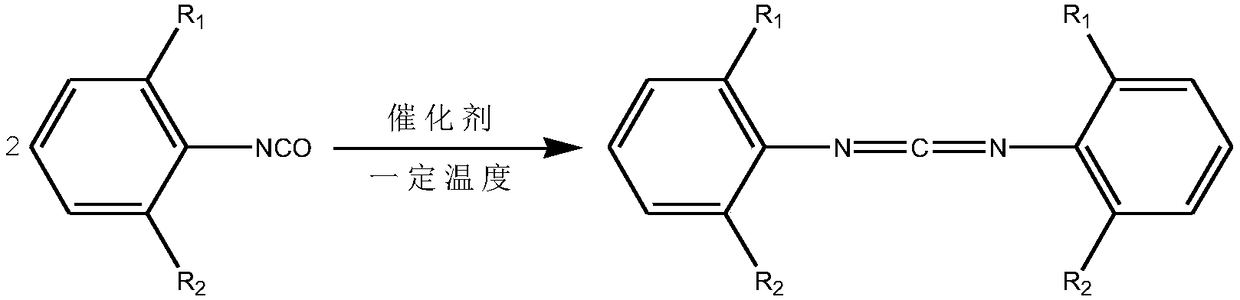

Method used

Image

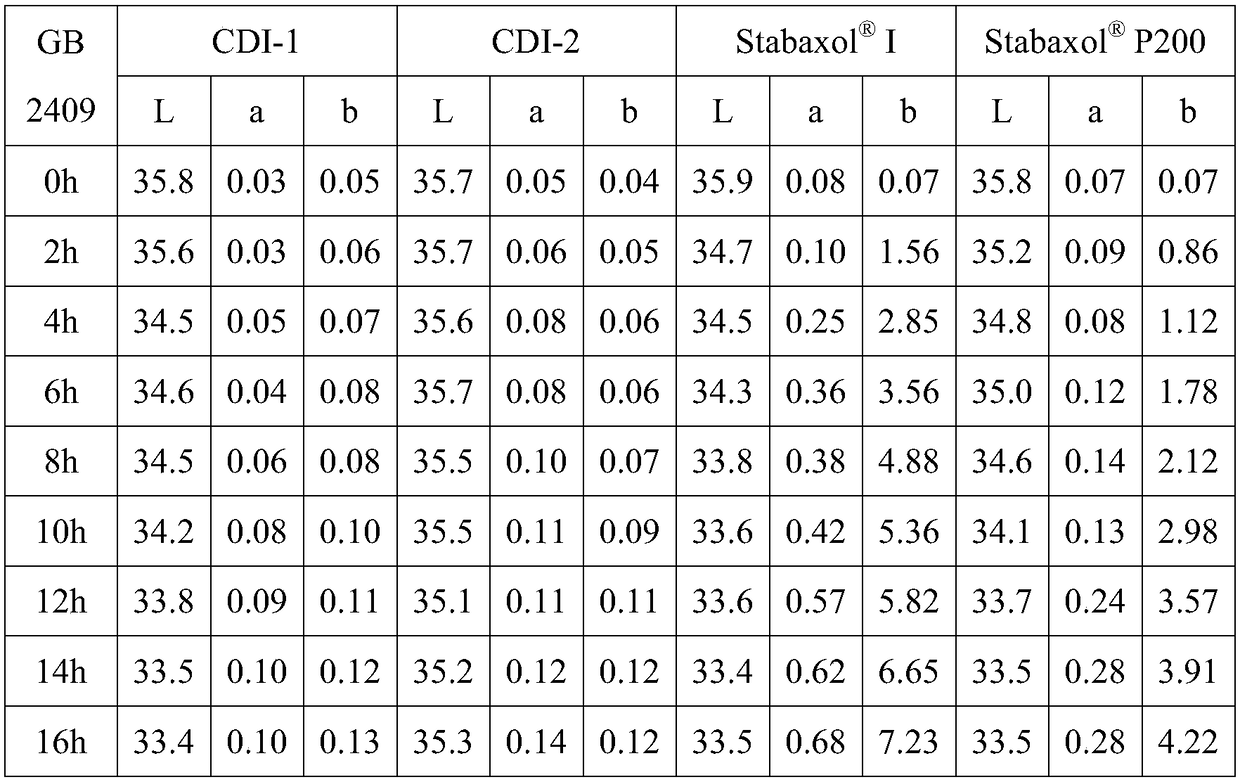

Examples

Embodiment 1

[0020] Under nitrogen flow, add 200g of 2,6-diethylphenyl isocyanate to a 250ml reaction vessel, while adding 1g of 1-methylcyclophosphene oxide, and react at 140℃ until the NCO content of the system is less than 0.5%. React for 10h to obtain a crude product. A rectifying column is used to rectify the synthesized crude product to obtain a colorless and transparent liquid carbodiimide compound. Weigh 100g of the colorless and transparent liquid carbodiimide compound into the reaction vessel, while adding 1g (3,5-di-tert-butyl-4-hydroxyphenyl) stearyl propionate and 0.5g 2 -Cyano-3,3-diphenyl ethyl acrylate was stirred at 60°C for 1 hour to obtain a uniform and stable composition CDI-1.

Embodiment 2

[0022] Under nitrogen flow, add 200g of 2,6-dimethyl isocyanate to a 250ml reaction vessel, and at the same time add 0.5g of 1-methylcyclophosphene oxide, and react at 180°C until the NCO content of the system is less than 0.5%. The crude product was obtained in 10h. A rectifying column is used to rectify the synthesized crude product to obtain a colorless and transparent liquid carbodiimide compound. Weigh 100g of the colorless and transparent liquid carbodiimide compound into the reaction vessel, and at the same time add 1.2g of triethylene glycol ether-bis(3-tert-butyl-4-hydroxy-5-methylphenyl)propionic acid The ester and 0.6 g of 2-(2-hydroxy-3,5-bis(1,1-dimethylphenyl))-benzotriazole were stirred at 60° C. for 1 h to obtain a uniform and stable composition CDI-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com