Anti-sinking polyurethane (PU) transparent primer and preparation method thereof

A transparent primer and anti-sag technology, which is applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of low transparency, slow drying speed, and poor anti-sag properties, and achieve good transparency, easy polishing, Strong anti-sag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

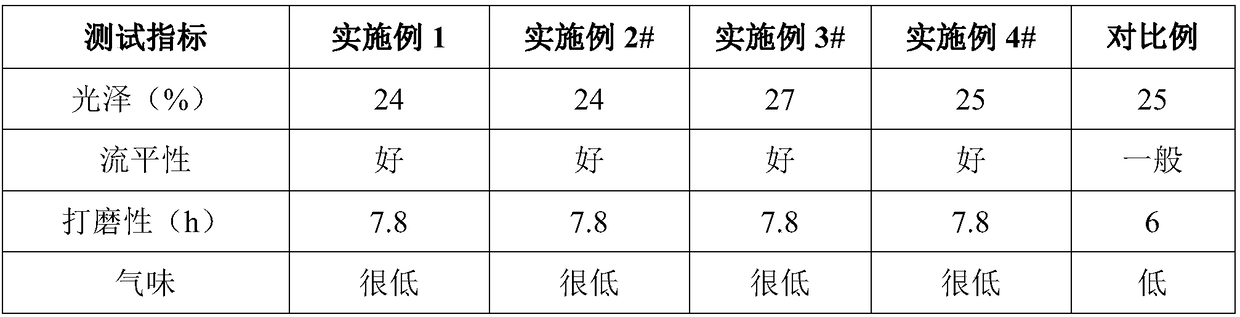

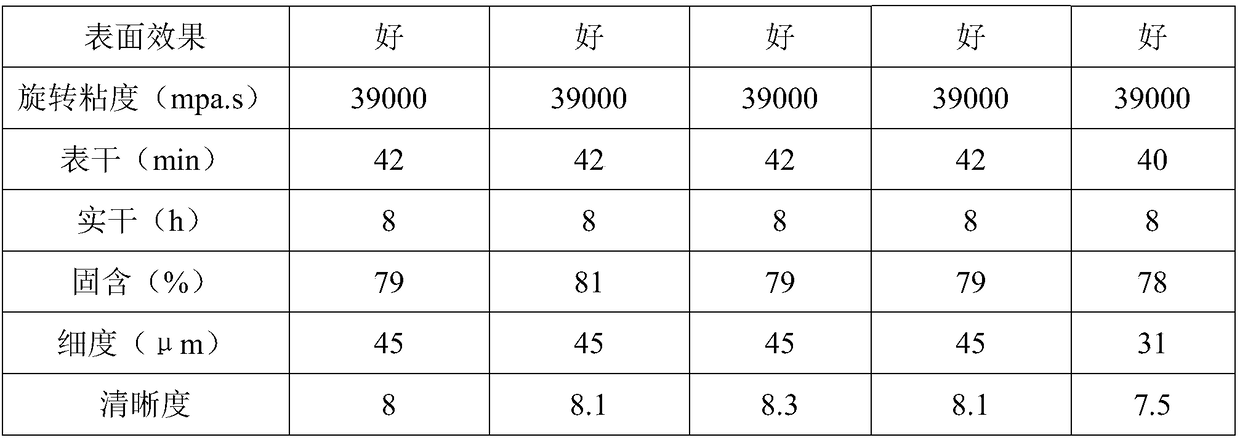

Examples

Embodiment 1

[0022] Preparation of anti-sag PU transparent primer

[0023] Raw materials: 36 parts of short oil alkyd resin, 15 parts of polyamide wax anti-settling slurry, 0.1 part of defoamer, 28 parts of transparent powder, 15 parts of talcum powder, 0.5 parts of zinc stearate, 2 parts of toluene, 3.4 parts of sec-butyl ester share.

[0024] Preparation steps:

[0025] (1) Mix and disperse short oil alkyd resin, anti-settling slurry and defoamer at 500 rpm for 10 minutes;

[0026] (2) Add transparent powder, talcum powder, and zinc stearate under stirring, and disperse at 1000 rpm until the fineness is ≤55 μm, and the dispersion temperature is 55°C;

[0027] (3) Add toluene and sec-butyl ester under stirring, and disperse at 1000 rpm for 3 minutes to obtain the product.

Embodiment 2

[0029] Preparation of anti-sag PU transparent primer

[0030] Raw materials: 40 parts of short oil alkyd resin, 10 parts of polyamide wax anti-settling slurry, 0.5 parts of defoamer, 20 parts of transparent powder, 20 parts of talc powder, 0.1 part of zinc stearate, 5 parts of toluene, 1 part of sec-butyl ester share.

[0031] Preparation steps:

[0032] (1) Mix and disperse short oil alkyd resin, anti-settling slurry and defoamer at 1000 rpm for 3 minutes;

[0033] (2) Add transparent powder, talcum powder, and zinc stearate under stirring, and disperse at 1500 rpm until the fineness is ≤55 μm, and the dispersion temperature is 55°C;

[0034] (3) Add toluene and sec-butyl ester under stirring, and disperse at 500 rpm for 8 minutes to obtain the product.

Embodiment 3

[0036] Preparation of anti-sag PU transparent primer

[0037] Raw materials: 30 parts of short oil alkyd resin, 20 parts of polyamide wax anti-settling slurry, 0.1 part of defoamer, 30 parts of transparent powder, 10 parts of talc powder, 1.5 parts of zinc stearate, 1 part of toluene, 5 parts of sec-butyl ester share.

[0038] Preparation steps:

[0039] (1) Mix and disperse the short oil alkyd resin, anti-settling slurry and defoamer at 600 rpm for 5 minutes;

[0040] (2) Add transparent powder, talc powder, and zinc stearate under stirring, and disperse at 1100 rpm until the fineness is ≤55 μm, and the dispersion temperature is 55°C;

[0041] (3) Add toluene and sec-butyl ester under stirring, and disperse at 600 rpm for 5 minutes to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com