Extraction system of torreya grandis essential oil and use method of system

A technology of extracting essential oils and torreya, which is applied in the direction of essential oils/spices, fat production, etc., can solve the problems of wasting resources, not using the torreya peel well, polluting the environment, etc., to reduce power consumption, extract thoroughly, reduce The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

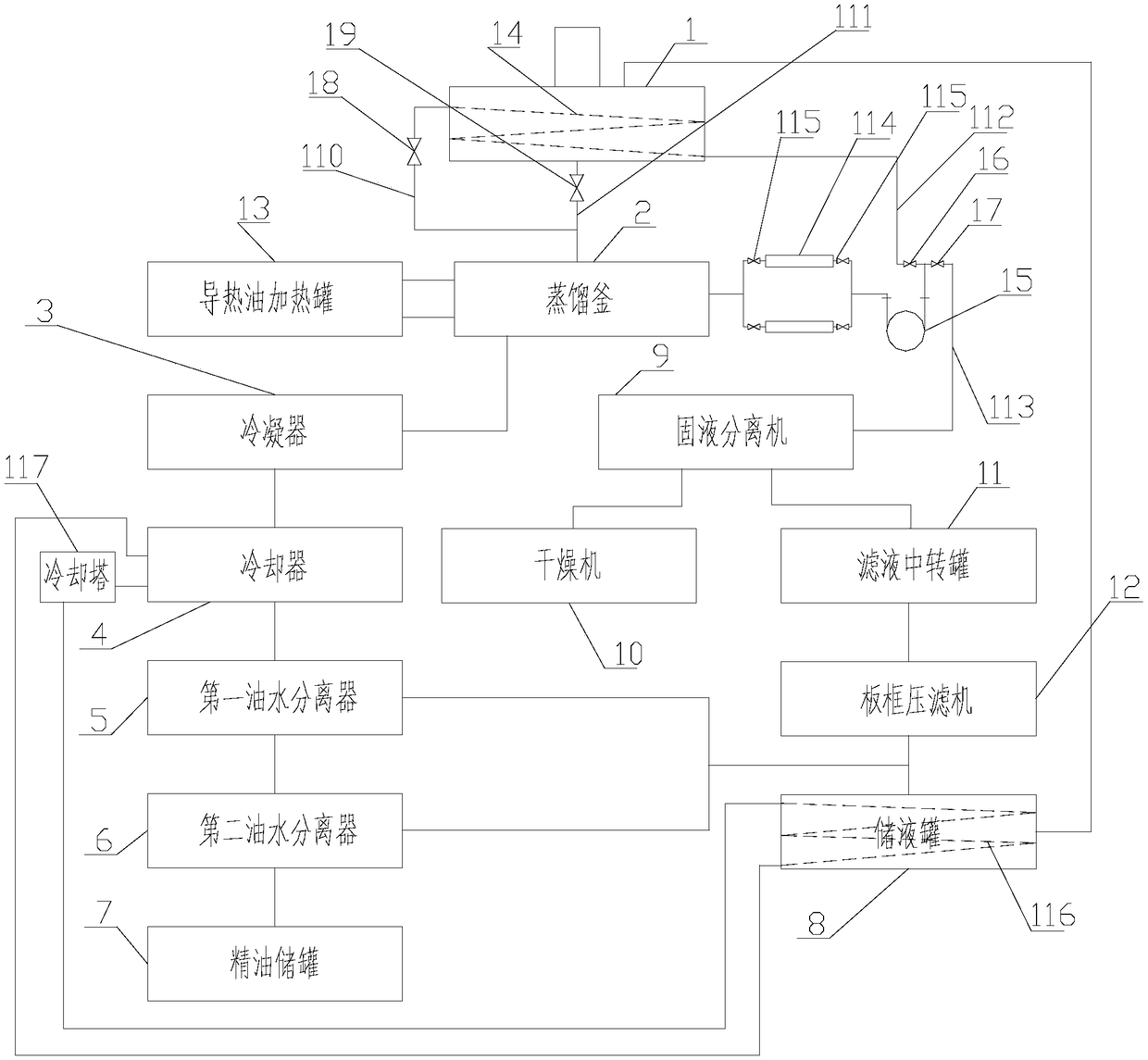

[0023] refer to figure 1 , a Chinese Torreya essential oil extraction system of the present invention comprises a stirring tank 1, a still 2, a condenser 3, a cooler 4, a first oil-water separator 5, a second oil-water separator 6, an essential oil storage tank 7, and a liquid storage tank 8 , residue treatment system, peristaltic pump 15, filter mechanism, first valve 16, second valve 17, third valve 18 and fourth valve 19, the first heating coil 14 is arranged in the stirring tank 1, the stirring The discharge port of the tank 1 is connected with the feed port of the still 2 through the first pipeline 111, and the steam outlet of the still 2, the condenser 3, the cooler 4 and the first oil-water separator 5 are connected sequentially from front to back , the oil outlet of the first oil-water separator 5 is connected with the inlet of the second oil-water separator 6, the oil outlet of the second oil-water separator 6 is connected with the essential oil storage tank 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com