Liquorice particles and preparation method thereof

A technology of licorice and granules, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems such as high sugar content, long production cycle, and lack of effective ingredients, and achieve The content of active ingredients is high, it is not easy to absorb moisture and get wet, and the effect of long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

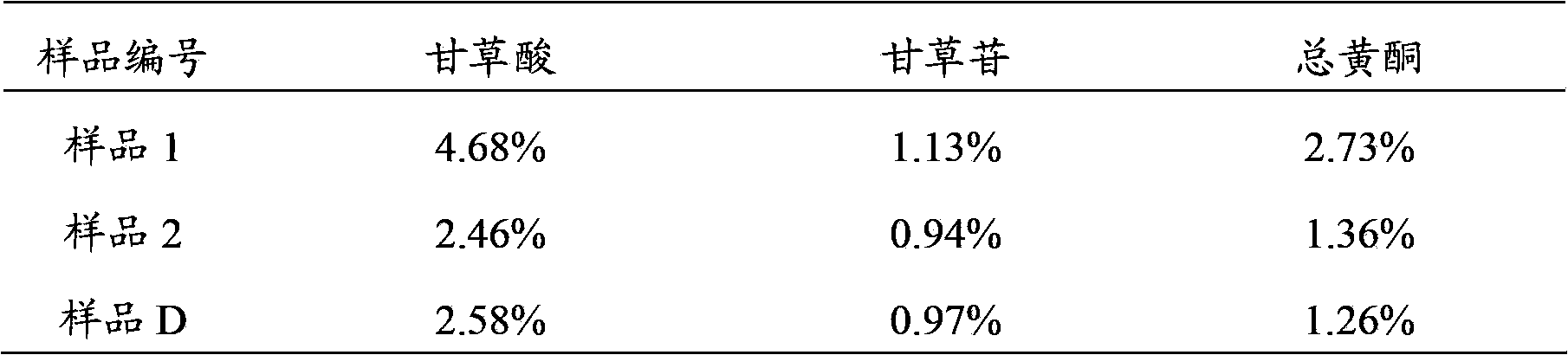

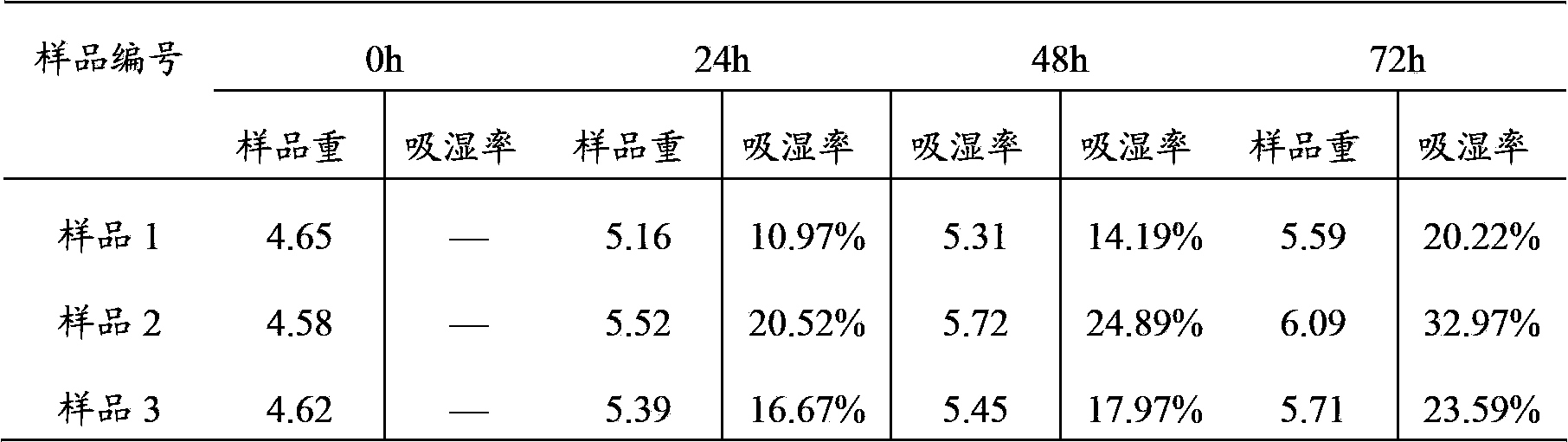

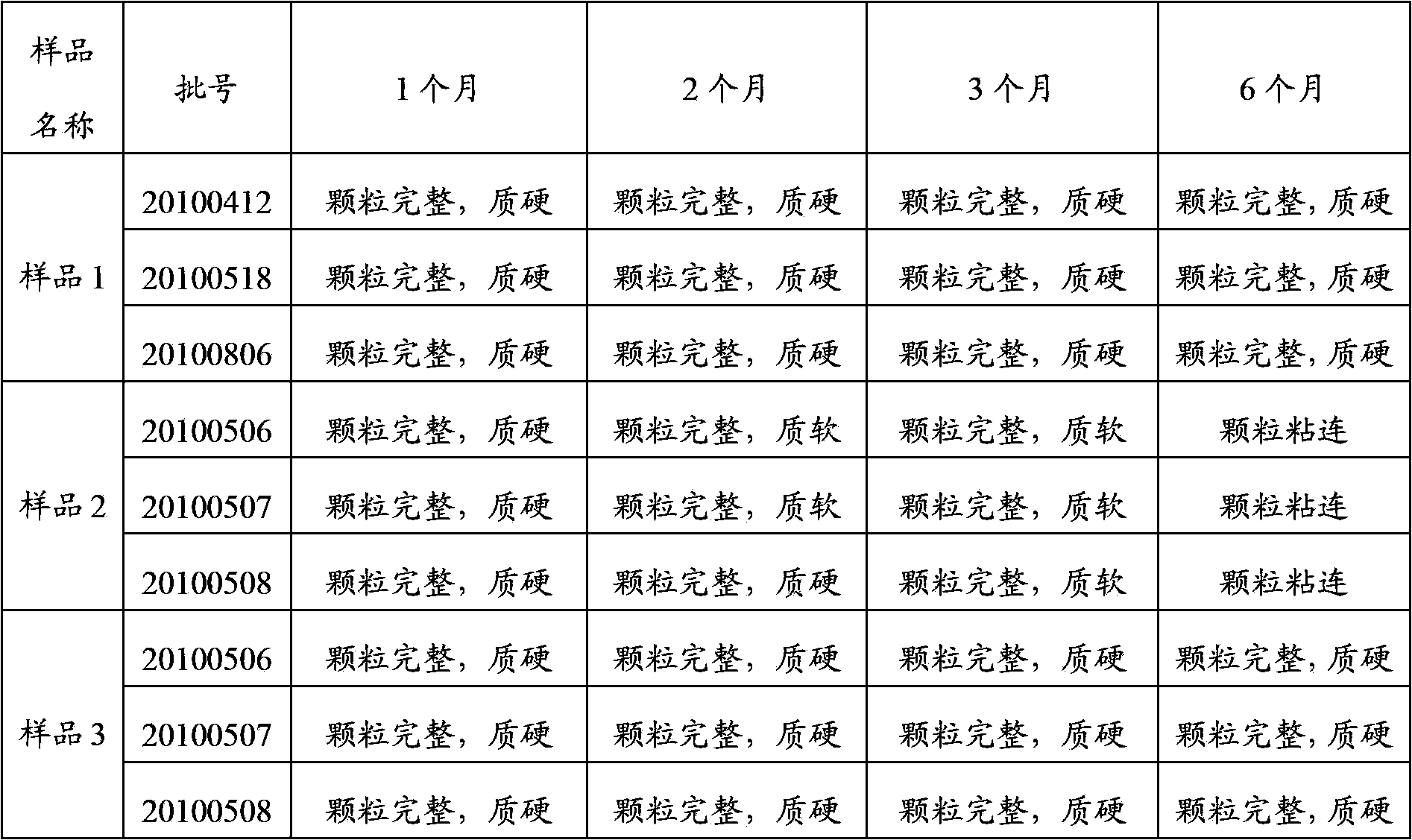

[0024] Example 1, Preparation Example 1 of Licorice Granules

[0025] Add 10 kg of licorice into the hot reflux low-temperature extraction pot, add 55% ethanol solution 12 times, soak for 30 minutes to make the medicinal materials soak. Pass in hot steam, control the pressure in the tank to 40-50Kpa, and perform low-temperature extraction at a temperature of 65°C. Extract 8 times, 20min each time, and concentrate while extracting until the extract is basically colorless and the extraction is complete. Pump out all the extracts to a concentration tank, and control the temperature at 60°C to concentrate to a clear cream with a specific gravity of 1.10. Add 0.5% (v / v) chitosan clarifier to the concentrated solution, stir well, stand for 12h, filter, and take the supernatant. The supernatant was concentrated under reduced pressure to a thick paste with a relative density of 1.25, 500 g of polyvinylpyrrolidone, 500 g of hydroxypropyl cellulose, and 1000 g of maltodextrin were added a...

Embodiment 2

[0026] Example 2: Preparation Example 2 of Licorice Granules

[0027] Add 10 kg of licorice to the hot reflux low temperature extraction pot, add 50% ethanol solution 15 times, soak for 30 minutes to make the medicinal materials soak. Pass in hot steam, control the pressure in the tank to 40-50Kpa, and perform low-temperature extraction at a temperature of 70°C. Extract 6 times, 30 minutes each time, and concentrate while extracting until the extract is basically colorless and the extraction is complete. Pump out all the extracts to a concentration tank, and control the temperature at 65°C to concentrate to a clear cream with a specific gravity of 1.10. Add 1% (v / v) chitosan clarifier to the concentrated solution, stir evenly, stand for 12h, filter, and take the supernatant. The supernatant was concentrated under reduced pressure to a thick paste with a density of 1.25, and 600 g of polyvinylpyrrolidone, 600 g of hydroxypropyl cellulose, and 1200 g of maltodextrin were added and...

Embodiment 3

[0028] Example 3 Preparation Example 3 of Licorice Granules

[0029] Add 10 kg of licorice to the hot reflux low-temperature extraction pot, add a 60% ethanol solution 14 times, soak for 30 minutes to make the medicinal materials soak. Pass in hot steam, control the pressure in the tank to 40-50Kpa, and perform low-temperature extraction at a temperature of 60°C. Extract 6 times, 30 minutes each time, and concentrate while extracting until the extract is basically colorless and the extraction is complete. Pump out all the extracts to a concentration tank, and control the temperature at 70°C to concentrate to a clear cream with a specific gravity of 1.10. Add 1% chitosan clarifier to the concentrated solution, stir evenly, let stand for 12h, filter, and take the supernatant. The supernatant was concentrated under reduced pressure to a thick paste with a density of 1.3, and 600 g of polyvinylpyrrolidone, 650 g of hydroxypropyl cellulose, and 1500 g of maltodextrin were added, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com