Steam pot for steaming mixtures

A mixture and clinker technology, applied in the preparation of alcoholic beverages, etc., to achieve the effects of low cost, easy maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

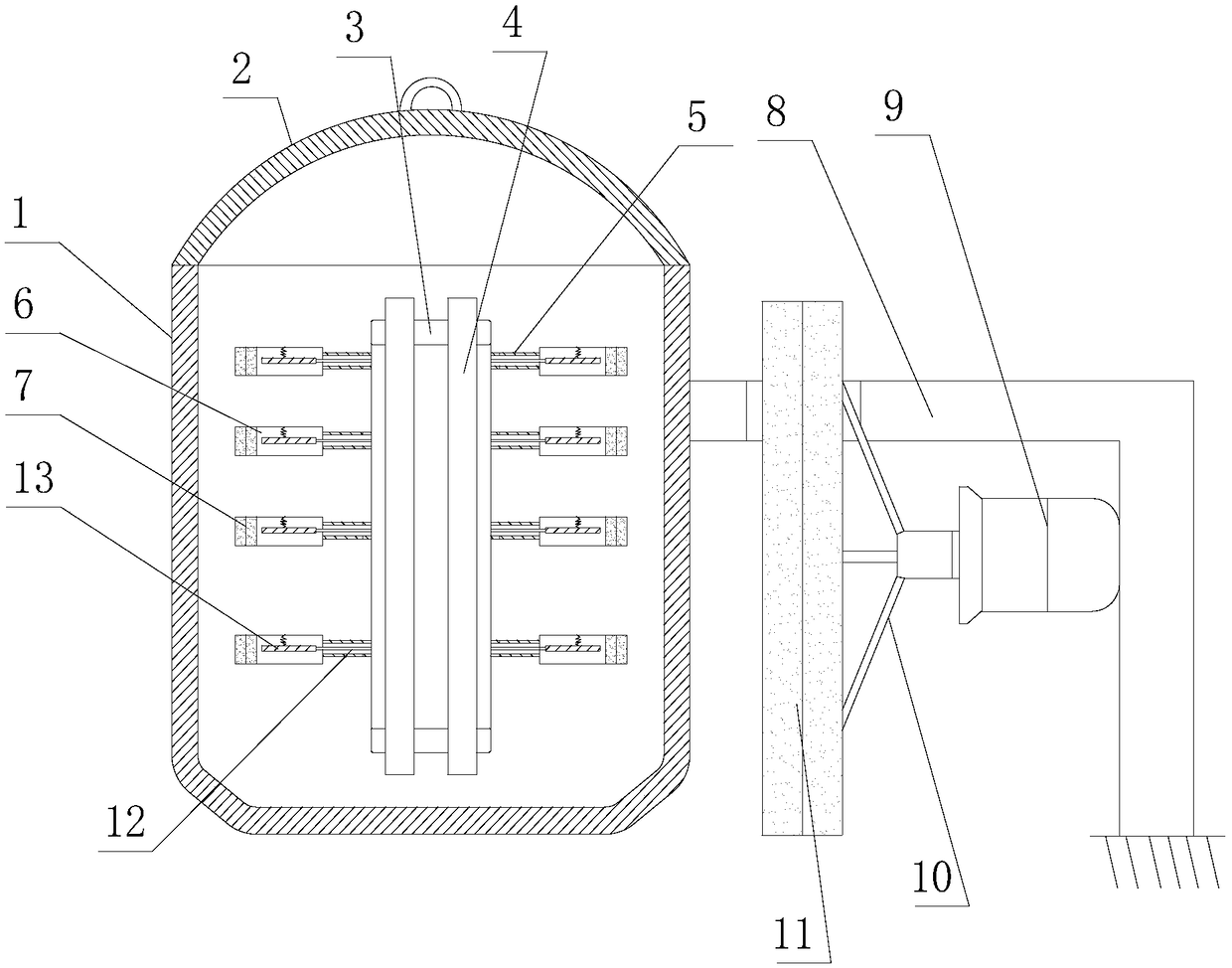

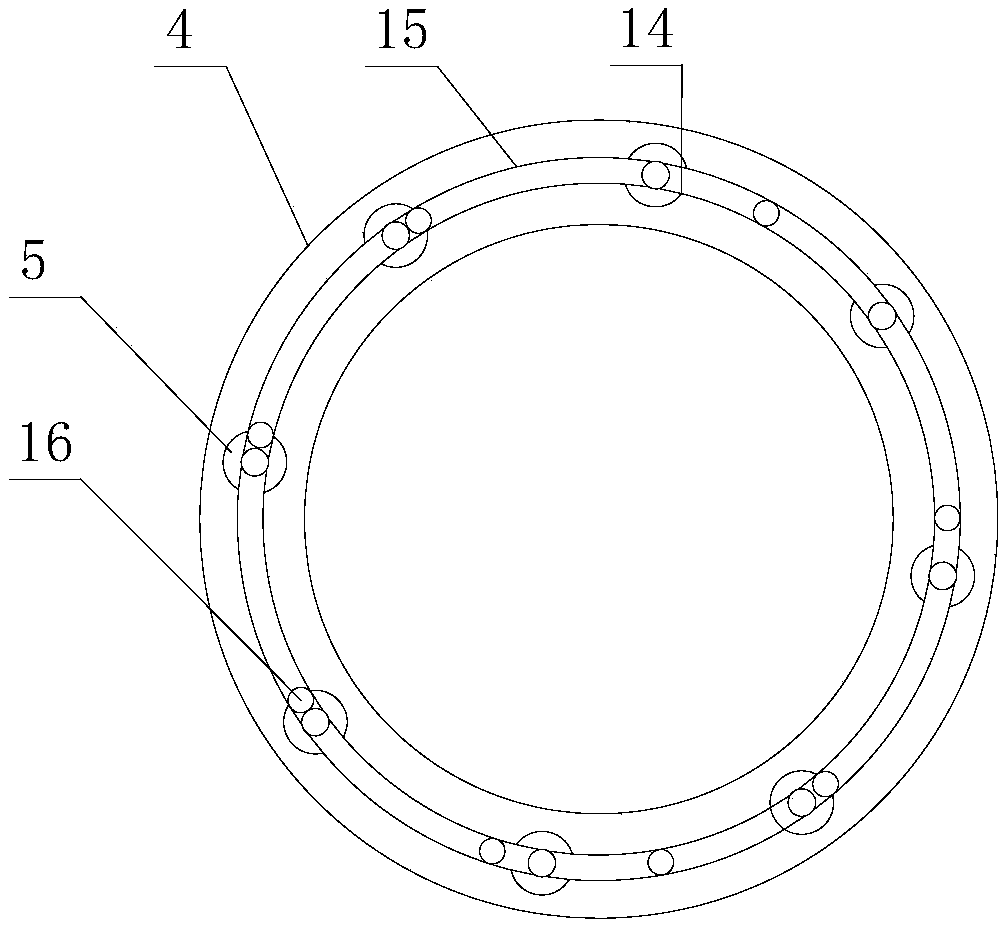

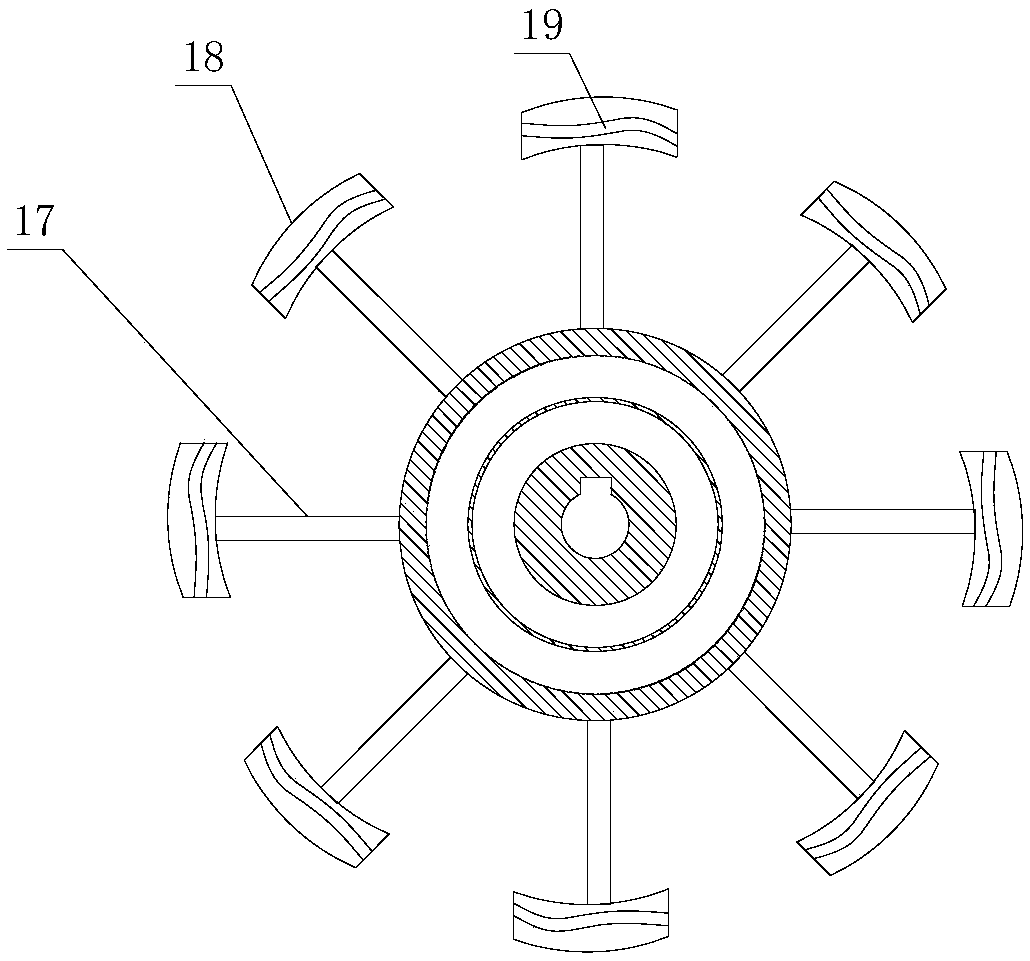

[0021] The reference signs in the drawings of the description include: pot body 1, cover body 2, gear 3, ring gear 4, first support rod 5, material chamber 6, first strong magnet 7, bracket 8, motor 9, second Two poles 10, the second strong magnet 11, the third pole 12, a toggle rod 13, a groove 14, an arc chamber 15, a sphere 16, a rotating rod 17, a blade 18, and a wing plate 19.

[0022] like figure 1 , 2 , 3 shows: a mixture clinker steamer, including a pot body 1 and a lid body 2 for opening and closing the upper opening of the pot body 1, and also includes a vertically arranged inside the pot body 1 and rotatably connected with the side wall of the pot body 1 The gear 3, the gear 3 is externally meshed with two ring gears 4, the two ring gears 4 are arranged in parallel and there is a gap between the two ring gears 4, and the two ring gears 4 are close to the opposite surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com