Feeding apparatus for embroidery machine

The technology of a feeding device and an embroidery machine is applied in the field of embroidery equipment, which can solve the problems of increasing the input of manpower and reducing the production efficiency of the embroidery machine, and achieve the effects of improving the production efficiency, facilitating the processing and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

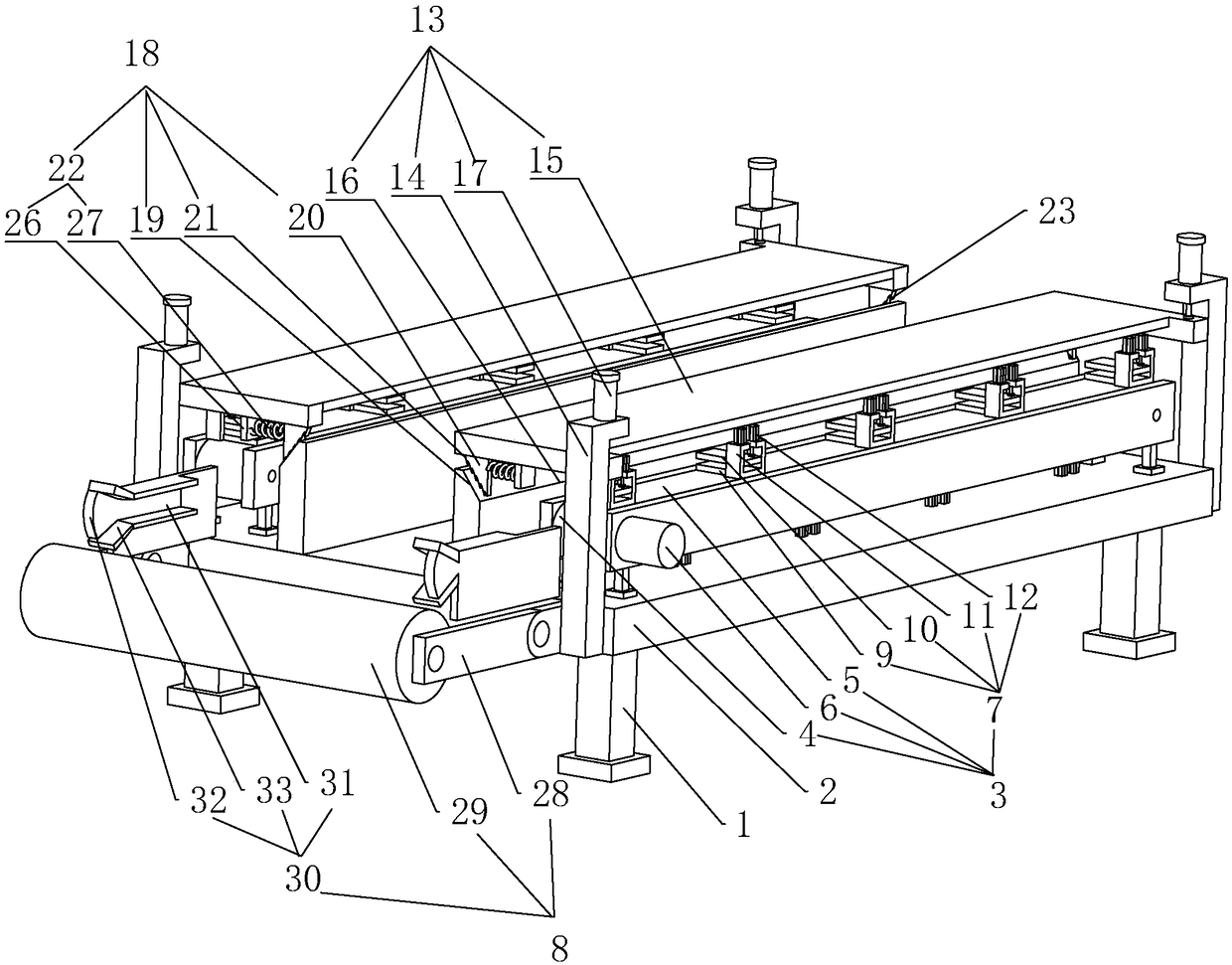

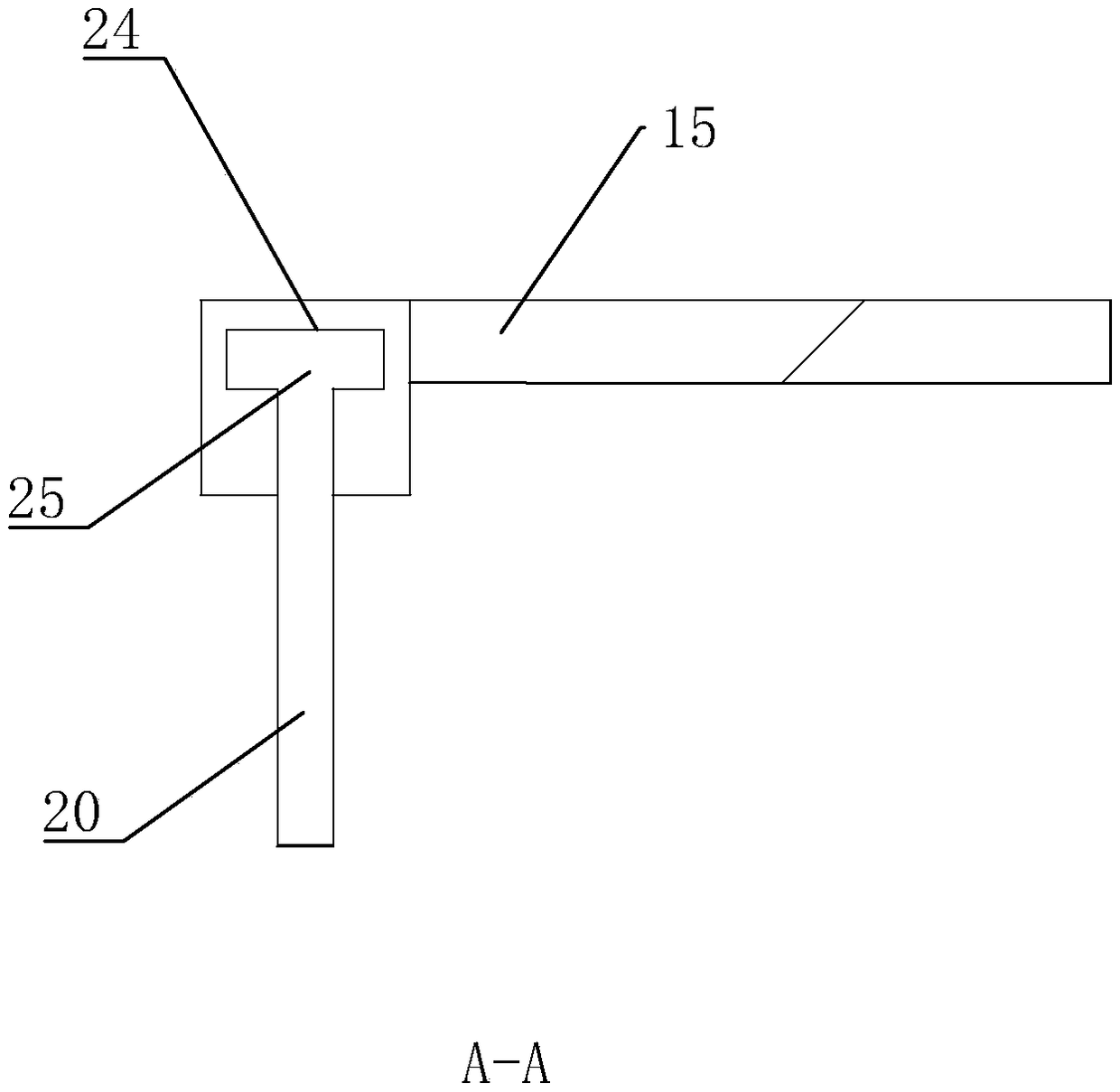

[0029] The present invention will be further described with reference to the accompanying drawings.

[0030] A kind of embroidery machine feeding device, such as figure 1 As shown, a bracket 1 is included, a workbench 2 is fixedly connected to the bracket 1, a feed mechanism 3 for convenient feeding is provided on the workbench 2, and a feed assembly 8 for convenient feeding is provided on one end of the workbench 2 .

[0031] Such as figure 1 As shown, a feeding mechanism 3 for convenient feeding is provided on the workbench 2. The feeding mechanism 3 includes a rotating wheel 4, a conveyor belt 5, a driving motor 6, and a clamping mechanism 7. Two groups of rotating wheels 4 are connected in rotation respectively. On both ends of the worktable 2; the conveyor belt 5 is wound on two sets of rotating wheels 4; the driving motor 6 is fixedly connected to one end of the working table 2, and the output shaft of the driving motor 6 is fixedly connected to the axis of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com