Rotor device of hydrapulper

A hydraulic pulper and rotor technology, which is used in textile and papermaking, raw material separation, fiber raw material processing, etc., can solve the problems of large power consumption, inability to ensure full circulation of pulp, etc., to achieve convenient operation and maintenance, and improve the disintegration effect. , the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

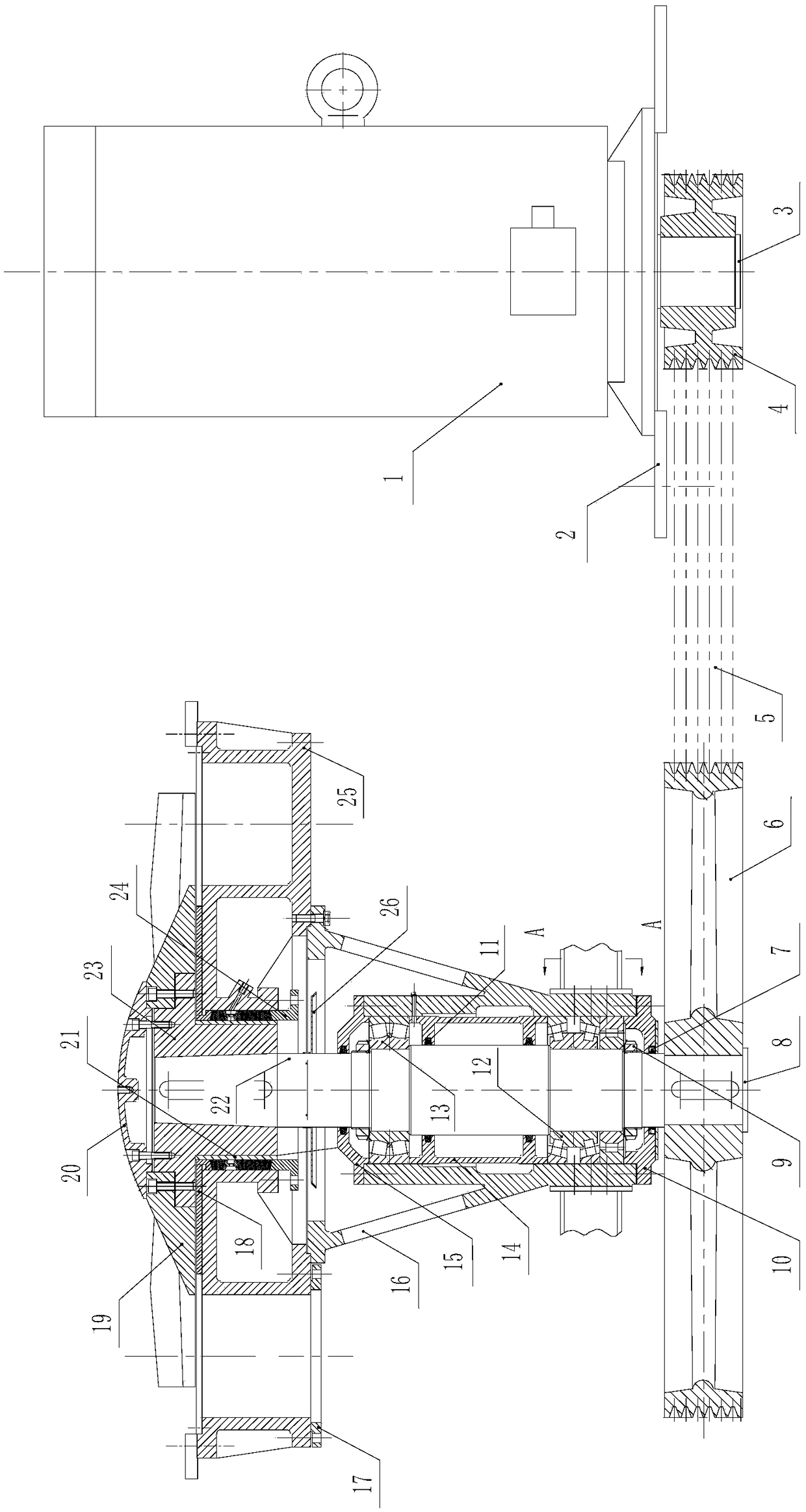

[0017] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

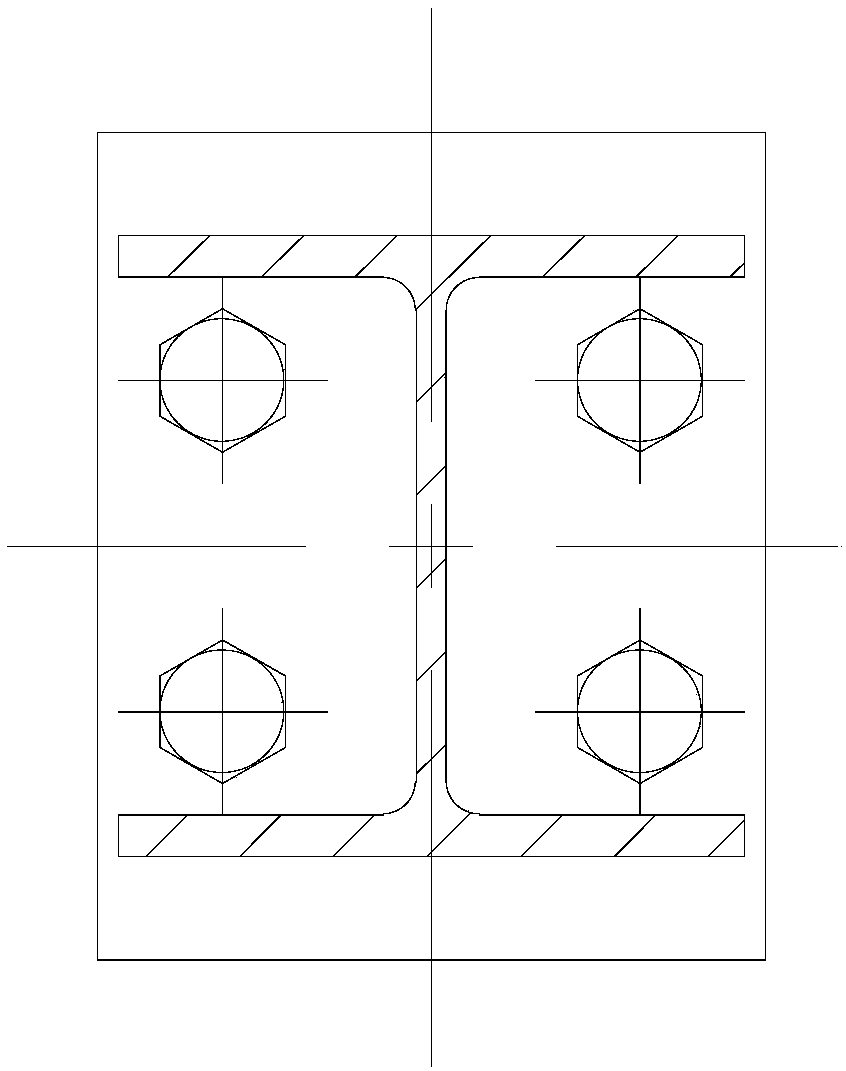

[0018] A hydraulic pulper rotor device, including: drive motor 1, motor mounting base 2, first pressure plate 3, driving pulley 4, belt 5, driven pulley 6, lip seal ring 7, second pressure plate 8 , lock nut 9, lower transparent cover 10, sealing felt ring 11, lower bearing group 12, upper bearing group 13, spacer sleeve 14, upper transparent cover 15, bearing seat 16, flange 17, flange plate 18, slurry Disk 19, sealing cover 20, sleeve 21, rotor 22, connecting shaft 23, mounting base 24, machine base 25 and blade 26, described driving motor 1 is fixedly installed on the motor mounting base 2, and described driving pulley 4 is installed on the output shaft of the driving motor 1, the first pressing plate 3 is fixedly installed on the bottom surface of the output shaft of the driving motor 1 and the first pressing plate 3 is pressed on the driving pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com