WNS type series natural gas energy-saving and environment-friendly boiler

An energy-saving and environment-friendly natural gas technology, applied in the field of boilers, can solve the problems of unfavorable protection of green water and green mountains, human ecological homes, increased energy consumption cost burden of boiler users, imperfection of fuel gas boilers, etc., to achieve full utilization of heat energy, significant energy saving, and reduction Effects of Air Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

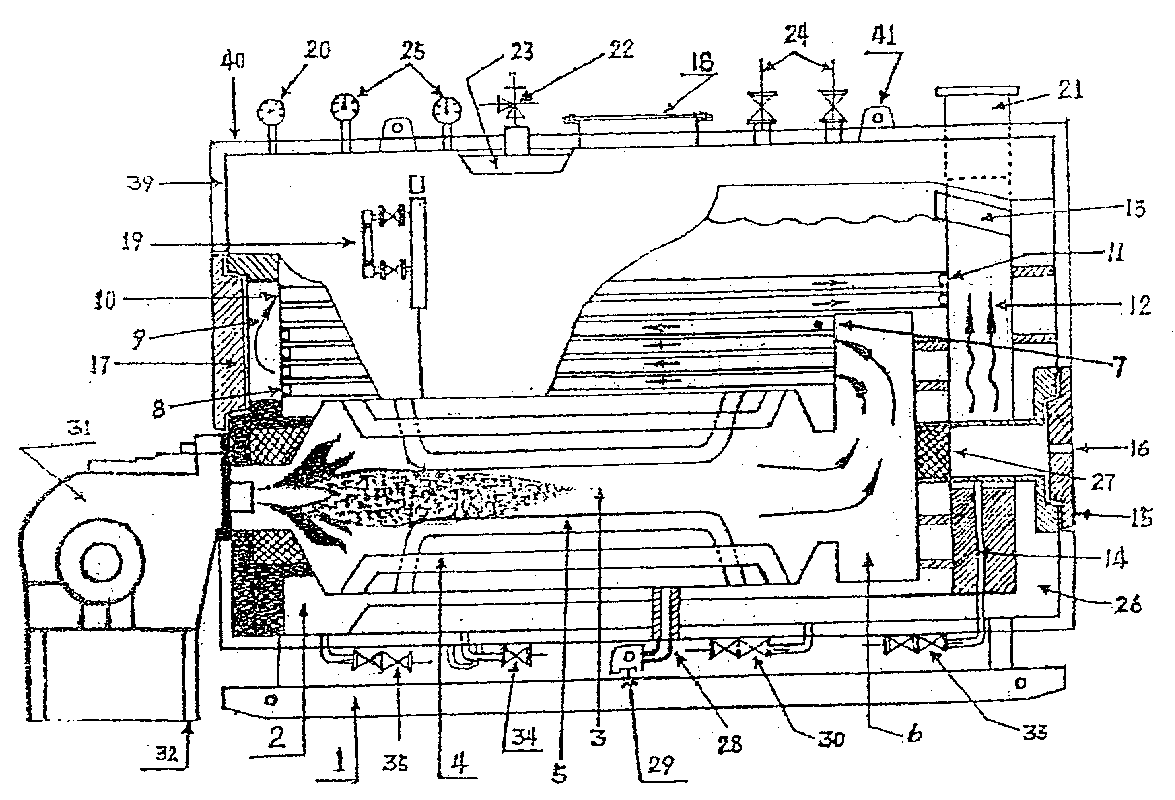

[0027] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described in further detail.

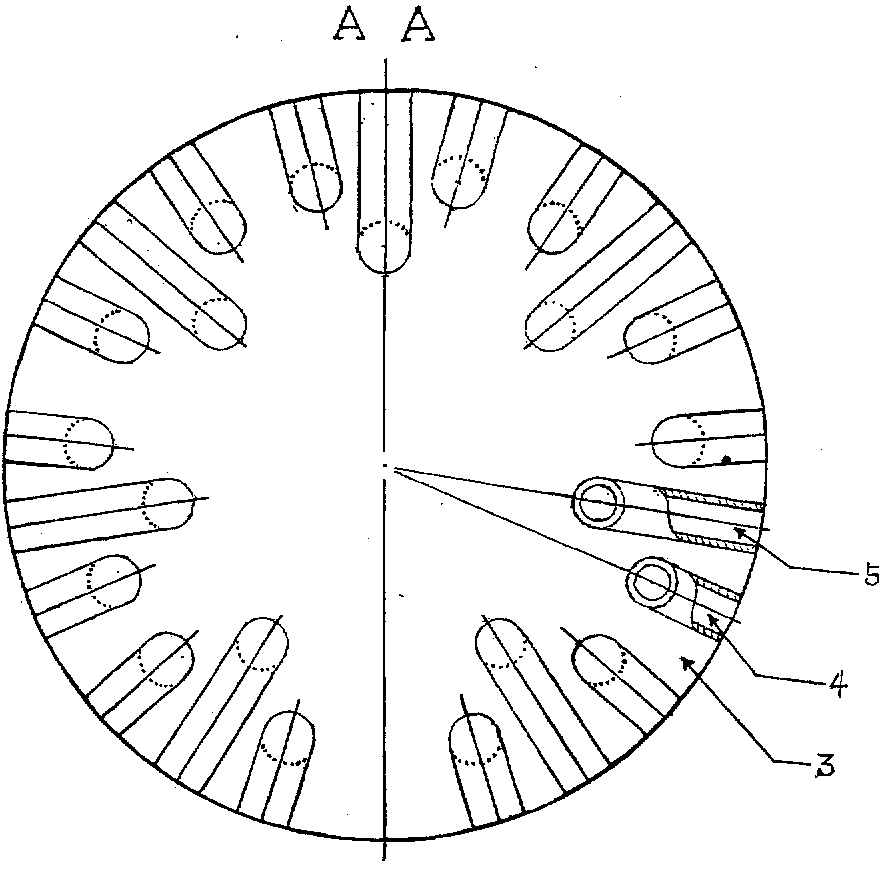

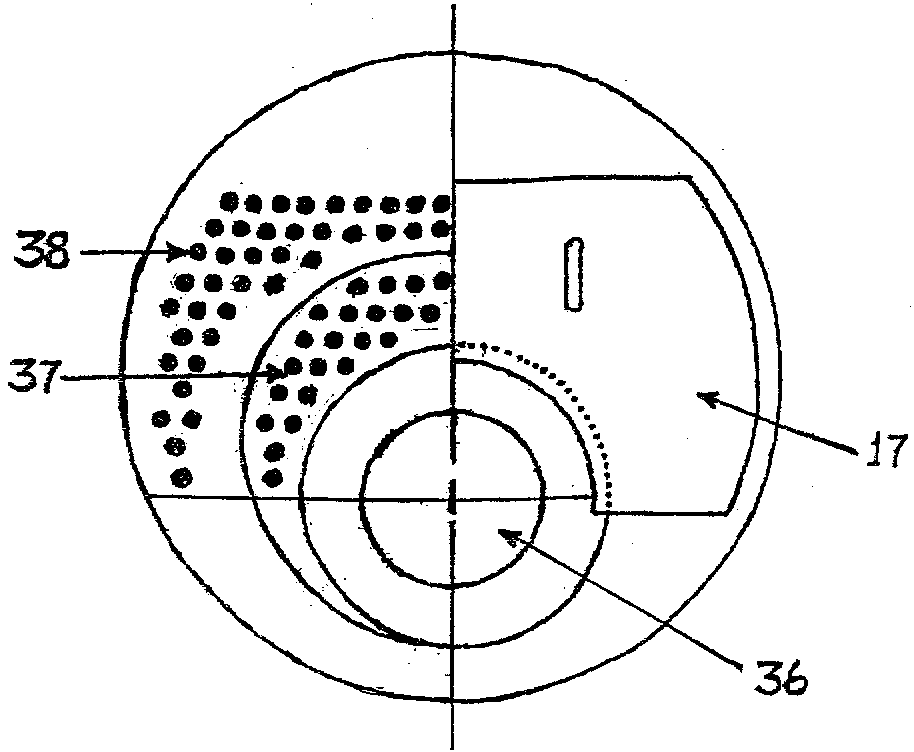

[0028] Implementation of the patent of the present invention: WNS type series natural gas energy-saving and environmental protection boiler, including boiler base 1, boiler main body water tank 2, boiler fire chamber combustion chamber first return journey 3, head circle high temperature circulating water pipe 4, second circle ultra high temperature circulating water pipe 5 and back combustion Chamber 6, boiler main body water tank 2 is placed on the boiler base, and the lower part of the boiler main body water tank 2 is provided with a boiler fire chamber combustion chamber-return 3, and the inner circumference of the boiler fire chamber combustion chamber-return 3 is welded with 6-20 high-temperature circulating water pipes 4 And two circles of 2-12 ultra-high temperature circulating water pipes 5, one end of the boiler fire chamber combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com