A method for measuring gas pressure

A gas pressure and measurement method technology, applied in the field of aerodynamics, can solve the problems of complex manufacturing process of pressure measuring paint and high cost of pressure fluorescent probes, and achieve the effects of low price, low cost and shortened response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

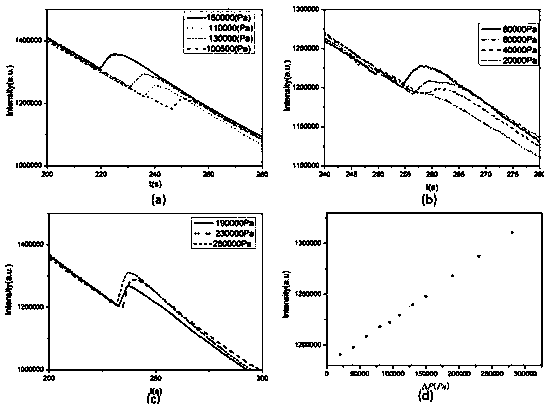

[0057] A gas pressure of 1 MPa is applied to the outer surface of the object to be measured, and the afterglow intensity changes are monitored at different stages of afterglow attenuation. From the results, it can be found that there is a regularity in the afterglow intensity changes at different stages. The pressure response of the afterglow material is the most sensitive in the decay time range of 150-250 seconds. The results are as follows image 3 As shown, image 3 This is the response result of the attenuation to the same pressure (1Mpa) measured at different times in Example 1 of the present invention.

Embodiment 2

[0059] In the afterglow interval where the afterglow intensity decays to 5% to 30% of the initial brightness, the same external gas pressure acts on the surface of the afterglow material, and the afterglow intensity change is linearly related to the attenuation degree, and the result is as follows Figure 4 As shown, Figure 4 It is the result curve of brightness attenuation to the initial afterglow brightness between 28% and 8%.

Embodiment 3

[0061] When the afterglow progresses to 240 seconds, when 20000, 40000, 60000, 80000, 100500, 110000, 130000, 150000, 190000, 230,000, 280000Pa gas pressure is applied to the surface of the afterglow material, the brightness change of the afterglow material is linearly related to the pressure. Thus, through the measurement of the afterglow brightness change, the standard curve of the measured gas pressure is obtained, and the result is as Figure 5 As shown, Figure 5 This is the standard curve of measuring gas pressure and the pressure-afterglow intensity result obtained in Example 3 of the present invention. Among them, (a) 20000, 40000, 60000, 80000 (b) 100500, 110000, 130000, 150000 (c) 190000, 230,000, 280000 (d) pressure vs. afterglow intensity change fitting curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com