Novel heat dissipation system based on heat dissipation housing

A technology of heat dissipation shell and heat dissipation system, which is applied in the directions of instruments, electrical digital data processing, digital data processing parts, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

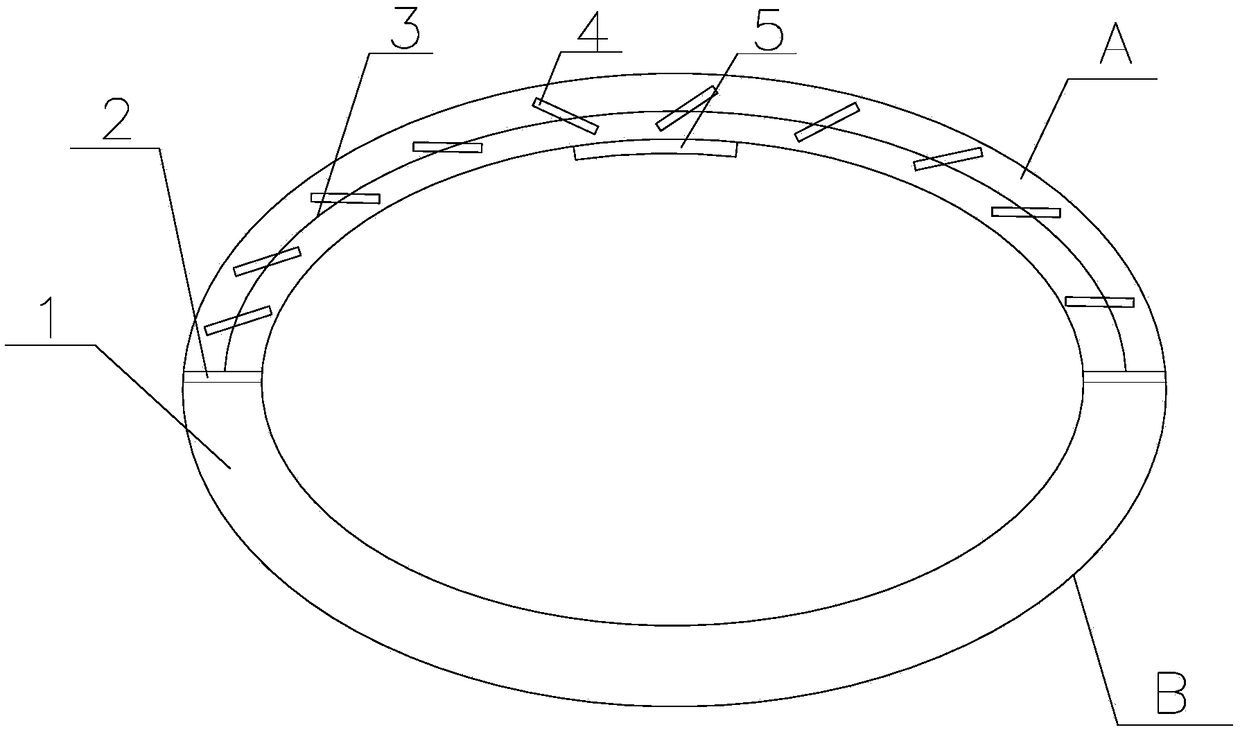

[0024] Such as Figure 1~2 As shown, the present invention is based on a novel heat dissipation system of a heat dissipation shell, including a shell 1, the shell 1 is an elastic rubber ring structure with a hollow inside, and a partition plate 2 is arranged inside the shell 1, and the partition plate 2 will The inner cavity of the housing 1 is evenly divided into two circular arc structures, A and B. A connecting rod 3 is arranged in part A of the housing 1, and a plurality of rotating rods 4 are connected to the connecting rod 3. Part A rotates along the connecting rod 3, liquid paraffin is housed in the part A, and some through holes are set on the partition plate 2, and a telescopic plate for blocking the through holes is provided on the partition plate 2, and one end of the telescopic plate is connected to the One end of the partition board is flush, and the other end is telescopic along the plane where the partition board is located; a temperature sensor 5 is arranged on...

Embodiment 2

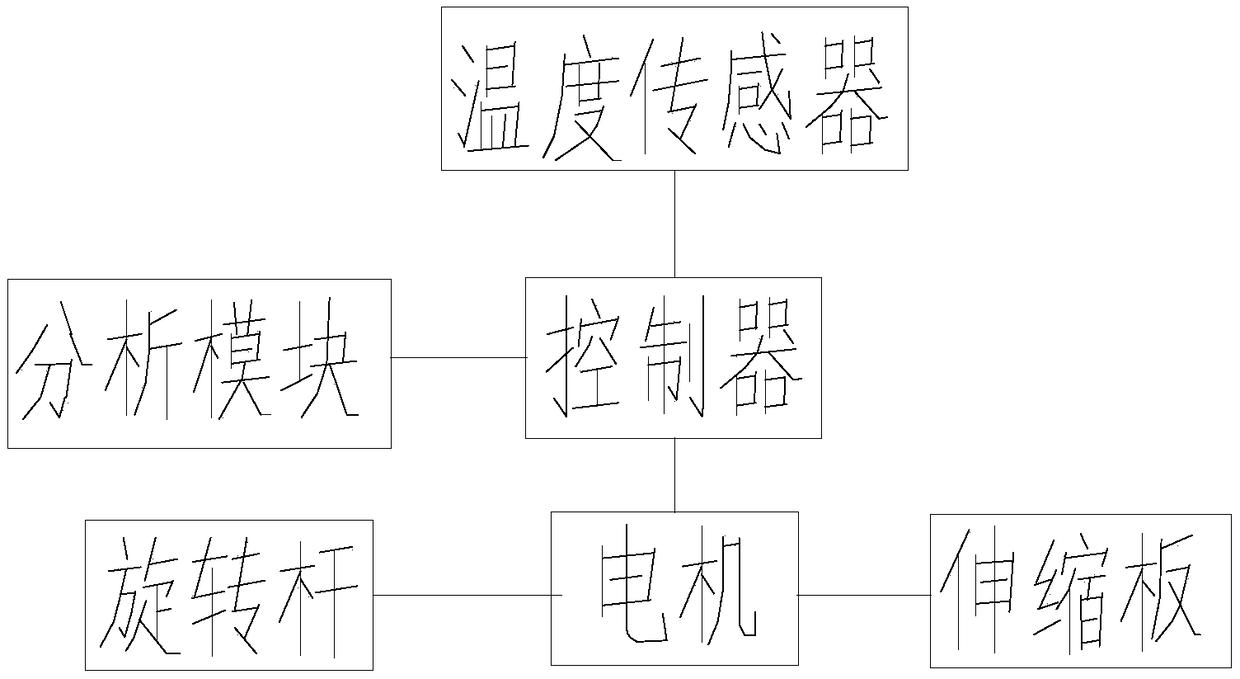

[0026] On the basis of embodiment 1, including a shell, the shell is provided with a controller, the controller is connected with a temperature sensor, a motor, the motor is connected with a telescopic plate, and the controller is connected with an analysis module; the temperature sensor is connected with On the casing, the motor is used to control the expansion and contraction of the expansion plate. When the temperature detected by the temperature sensor is higher than 30 degrees, the controller controls the motor to work, and the motor controls the expansion plate to shorten, so that the through hole on the partition plate is exposed; when the temperature sensor detects When the temperature is lower than 30 degrees, the controller controls the motor to work, and the motor controls the expansion plate to extend, so that the liquid paraffin in the shell is in the A part. The motor is also connected with a rotating rod. When the temperature detected by the temperature sensor is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com