Method for identifying continuous stirred tank reaction process based on deep neural network

A deep neural network and reaction process technology, applied in the field of online identification of continuous stirred tank reaction process, can solve the problems of inability to realize online monitoring and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

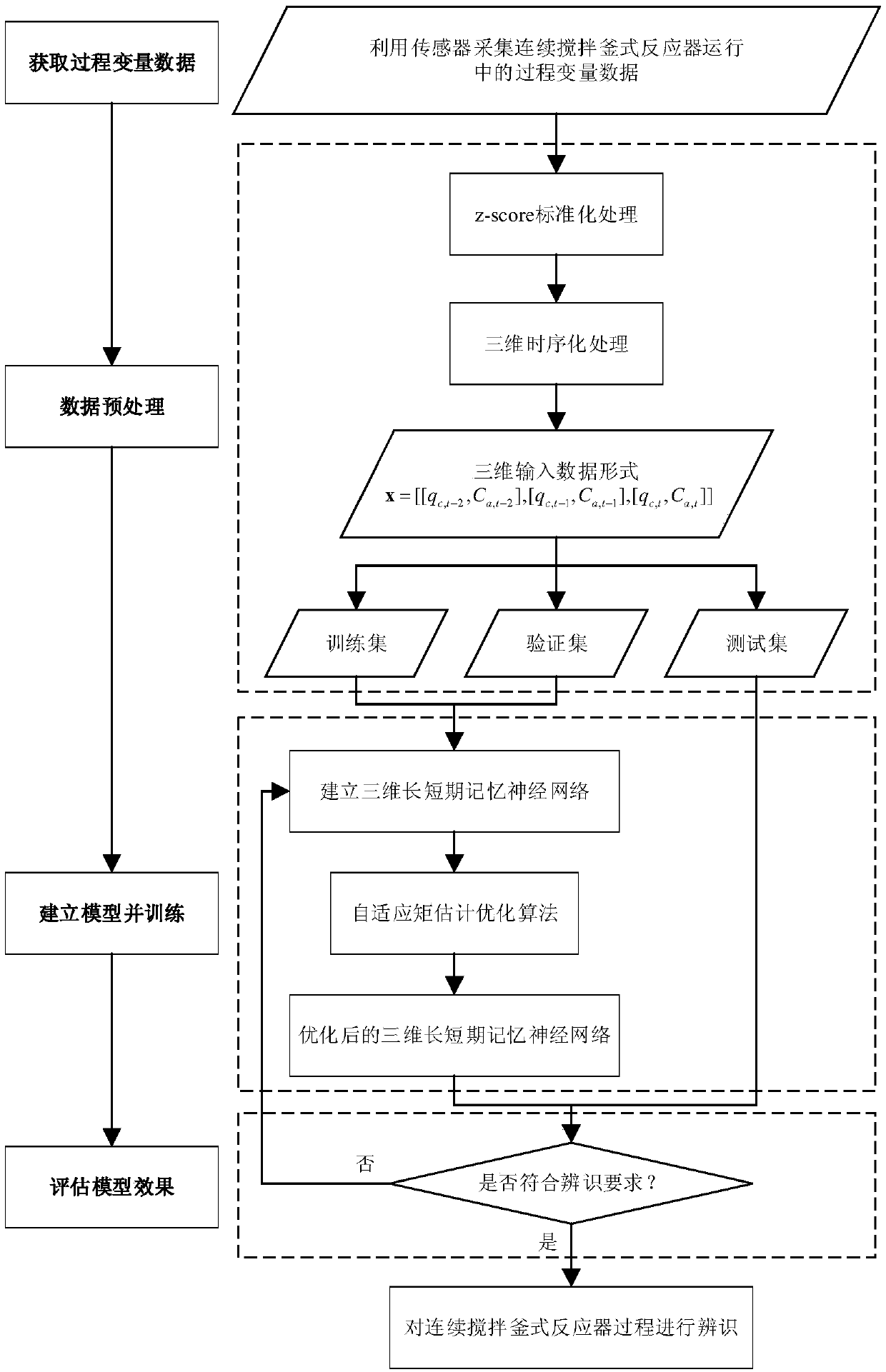

[0130] Example: A continuous stirred tank reaction process identification method based on deep neural network, the process is as follows:

[0131] (1) Carry out experiments and select to obtain experimental data

[0132] Operate the continuous stirred tank reactor experimental equipment, and obtain the cooling liquid volume flow data q through the sensor c and product concentration data C a , the units are l / min and mol / l respectively.

[0133] (2) Data preprocessing

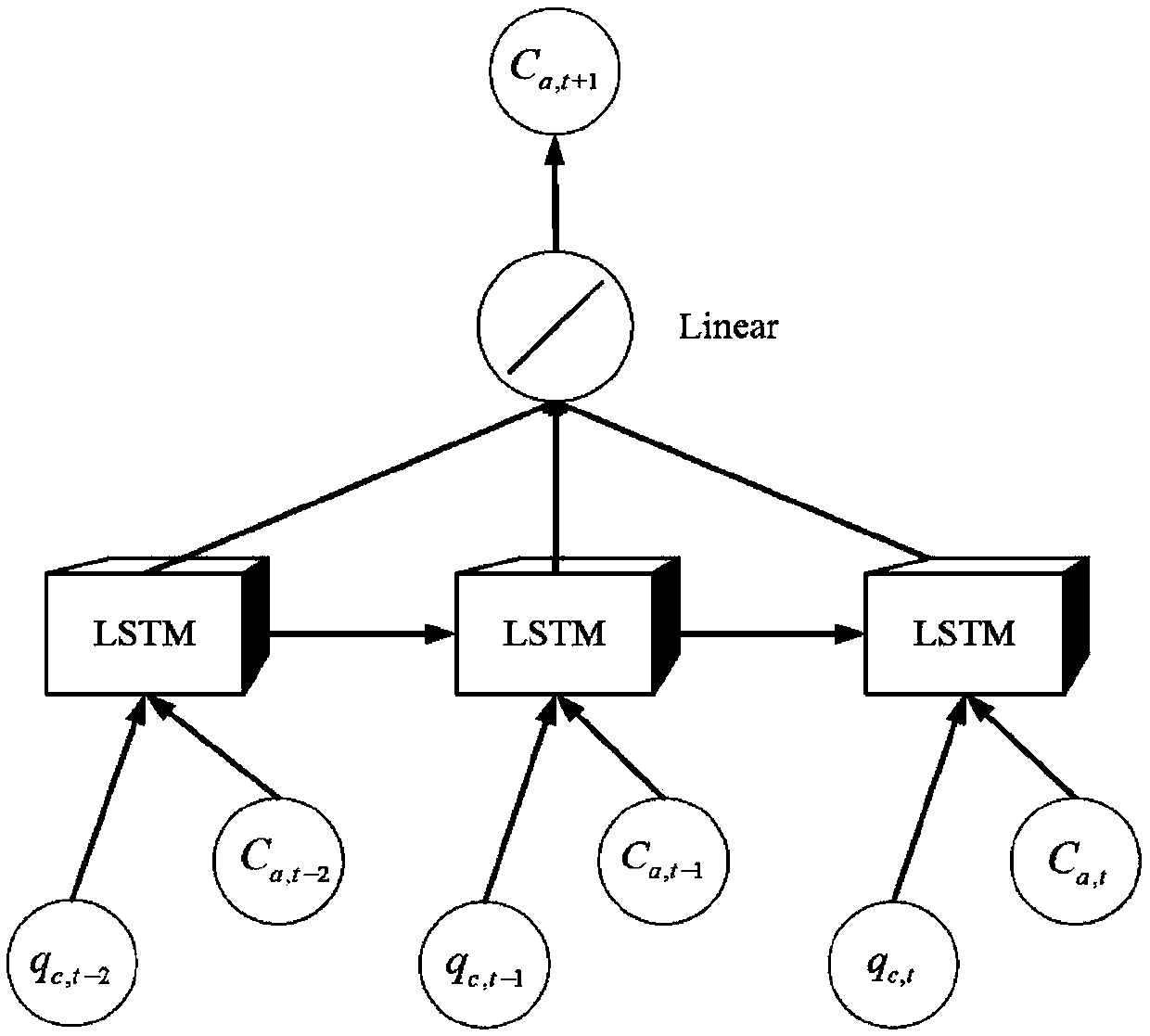

[0134] First, in order to eliminate the difference between variables due to different dimensions, the original data is subjected to z-score standardization processing; then, 3 time lags (ie n=3) are selected based on experience, and the data is sorted through three-dimensional time-series processing into a three-dimensional input form; finally, the processed data is divided into training set, verification set and test set, and the number of samples is 60%, 10% and 30% of the total number of samples respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com