Multi-view camera-based bridge defect detecting device and detection image splicing method

A technology of defect detection and multi-camera, which is applied in the field of multi-camera-based bridge defect detection device and detection image stitching, can solve the problems of bridge defect detection and maintenance, bridge structure safety threat, and low data accuracy, and achieve convenient Splicing and fusion processing, improving the accuracy of image acquisition, and enhancing the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

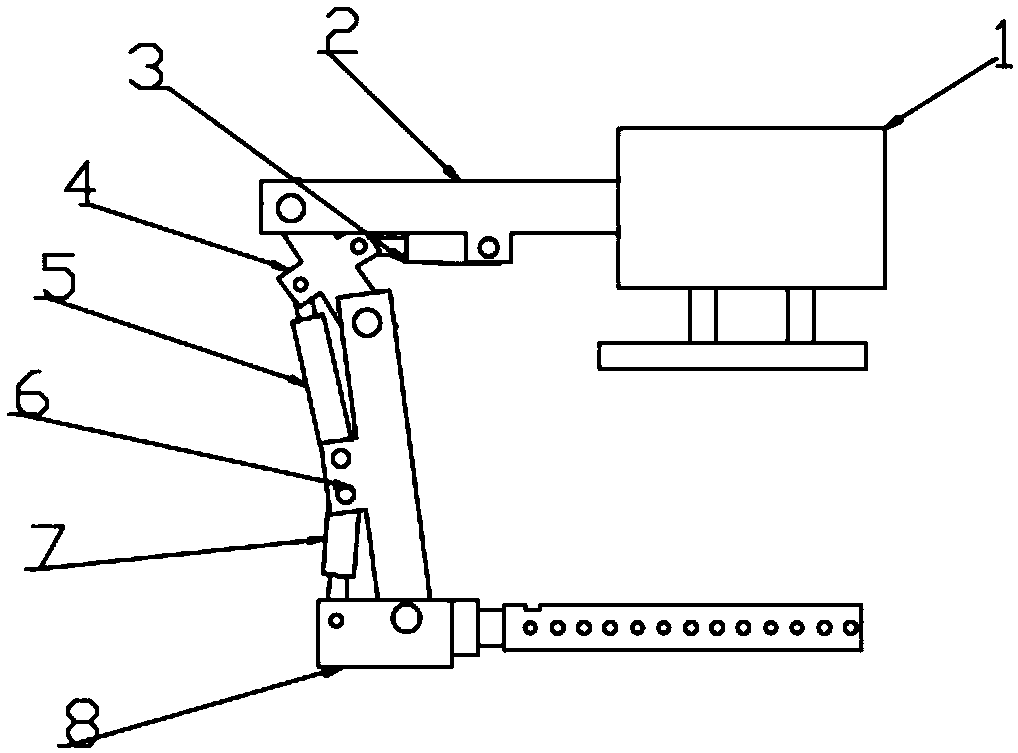

[0061] refer to figure 1 , a specific embodiment of the present invention is that the detection vehicle above the bridge deck extends a cross arm from the side, the first connecting bracket 4 is connected between the cross arm 2 and the longitudinal arm 6 through a rotating shaft, and the first hydraulic cylinder 3 is installed The other end is on the first connecting bracket 4 at the cross arm lug. Two hydraulic cylinders are installed on the trailing arm 6, wherein one end of the second hydraulic cylinder 5 is connected to the first connecting bracket 4, one end of the third hydraulic cylinder 7 is connected to the second connecting bracket 8, and the other ends of the two hydraulic cylinders share A lifting lug is fixed on the longitudinal arm 6 , and the collection mechanism assembly is fixed on the second connecting bracket 8 .

[0062] refer to Figure 5 , the working process of the present invention, because the pull rod of hydraulic oil cylinder can be used for adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com