Passive coupling induction coil

An induction coil and coil technology, applied in the field of radio frequency electronics, can solve the problems of difficult positioning of capacitor pins, inability to automate production, and inability to use automated quantitative production in the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the present invention will be further described below in conjunction with examples.

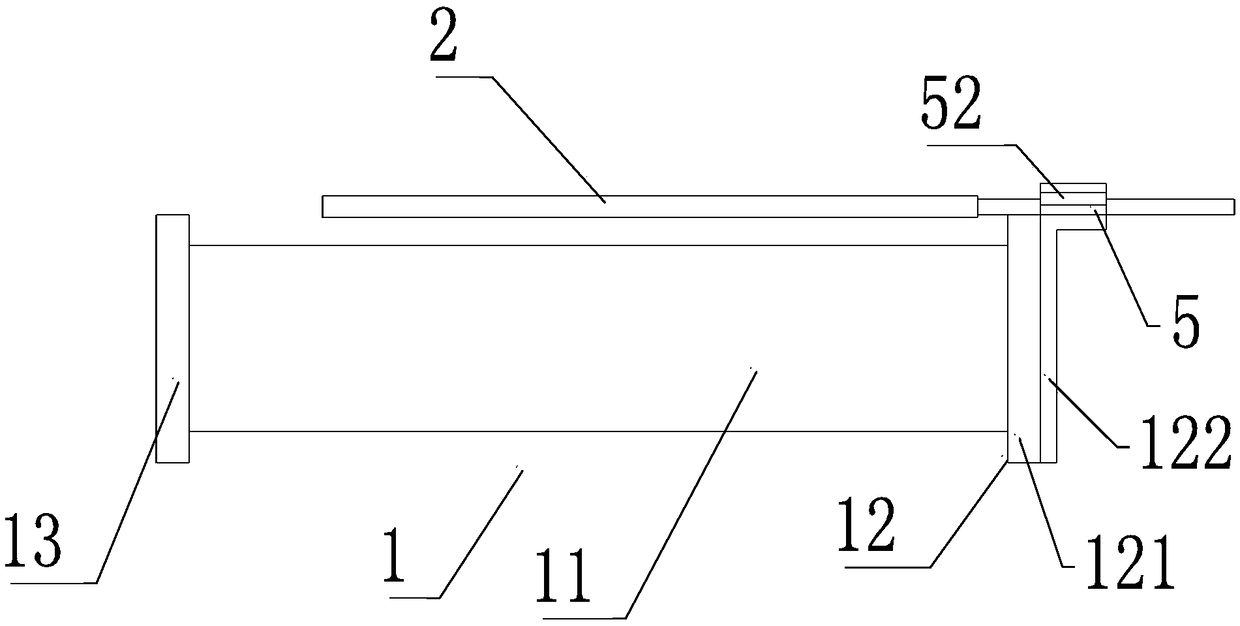

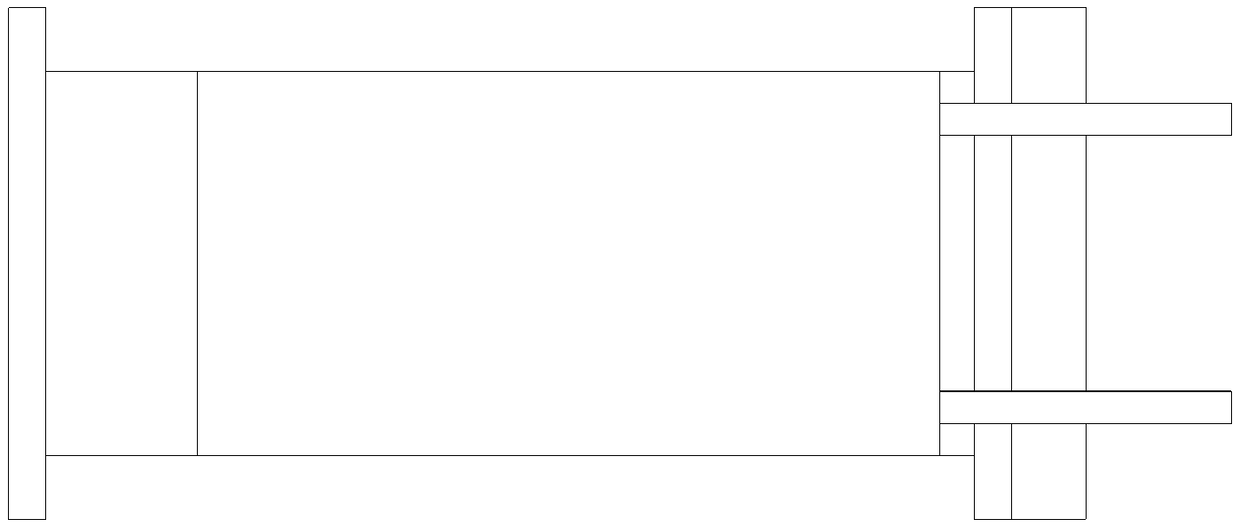

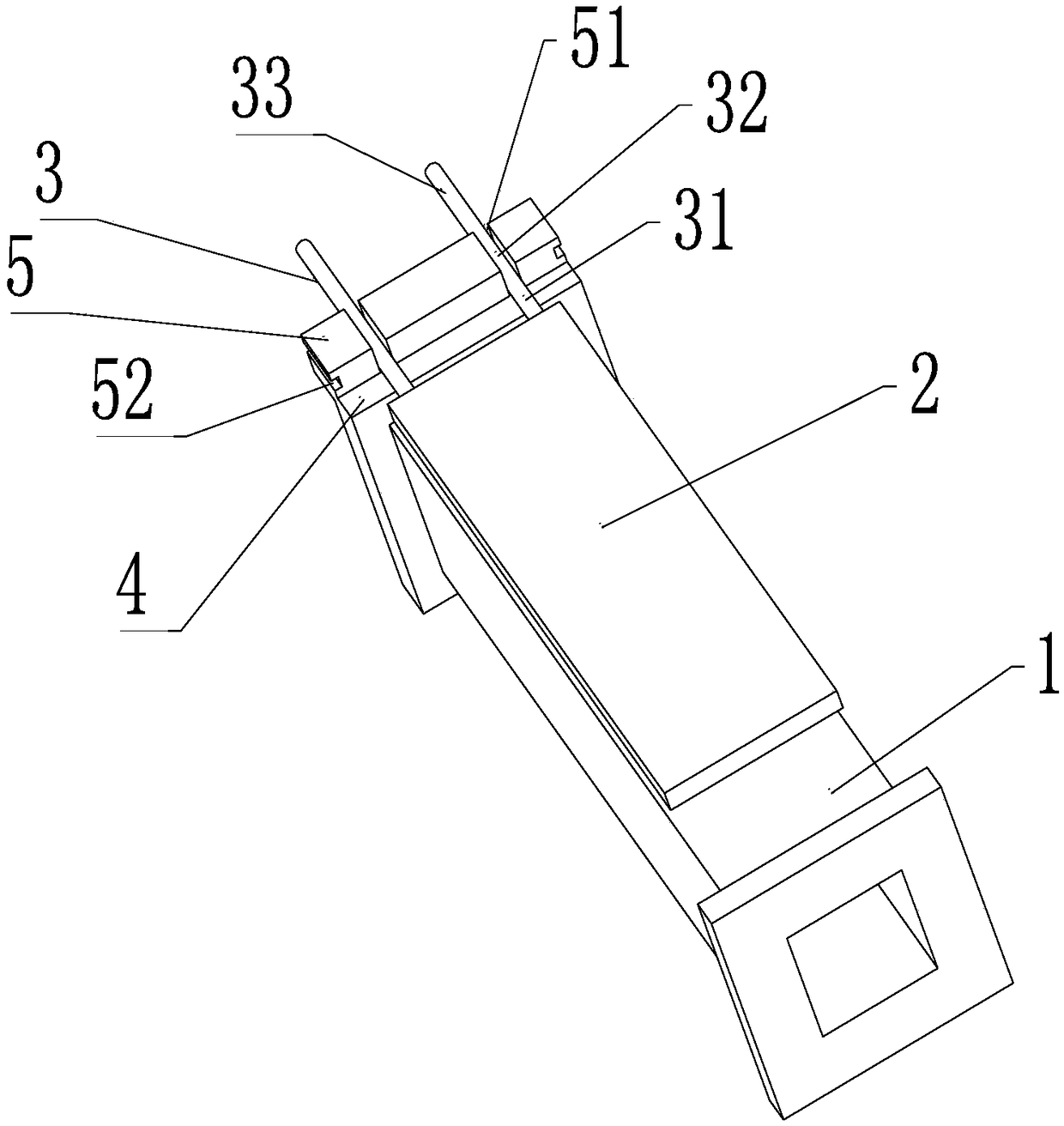

[0015] Such as Figure 1-5 As shown, the passively coupled induction coil includes a coil bobbin 1, a coil wound on the coil bobbin, and a capacitor connected to the coil. The coil bobbin includes a bobbin body 11. In the axial direction of the bobbin body, the bobbin One end of the body is provided with a first rib 12, and the other end is provided with a second rib 13. In the direction of the axis of the skeleton body, the outer edge of the first rib has an end surface for mounting with the capacitor. The upper end far away from the second gear has a bump 5, which has two grooves 51 spaced apart and pulled through at both ends; the capacitor has two pins 3, each corresponding to a groove, and the first A section of stitches 31, a second section of pins 32, and a third section of pins 33 are formed. The first section of pins is located between the inner en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com