Electric vehicle battery heat dissipation device

A technology of heat dissipation device and electric vehicle, which is applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as poor rapid heat dissipation performance, and achieve the effect of improving air cooling heat dissipation efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

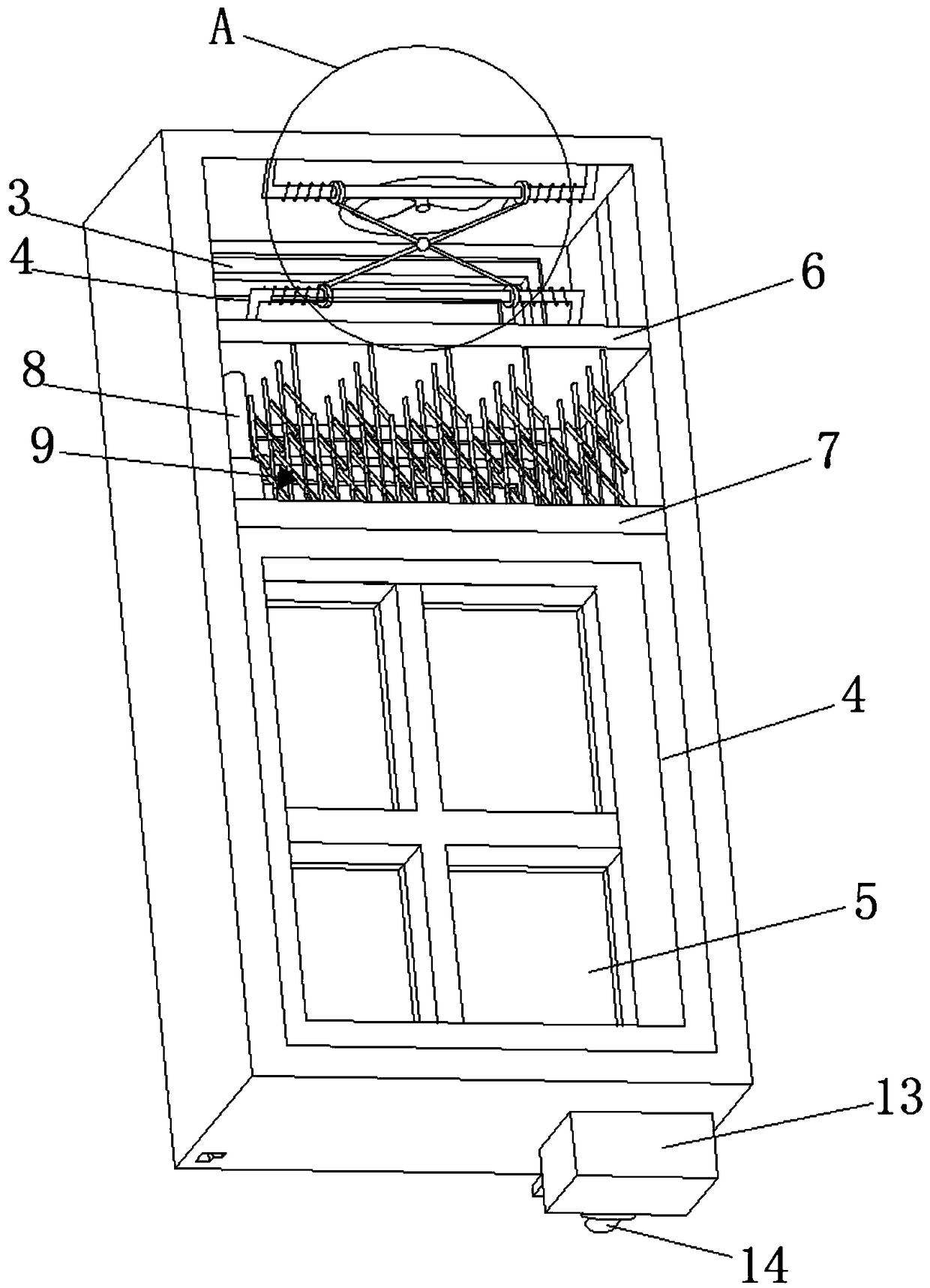

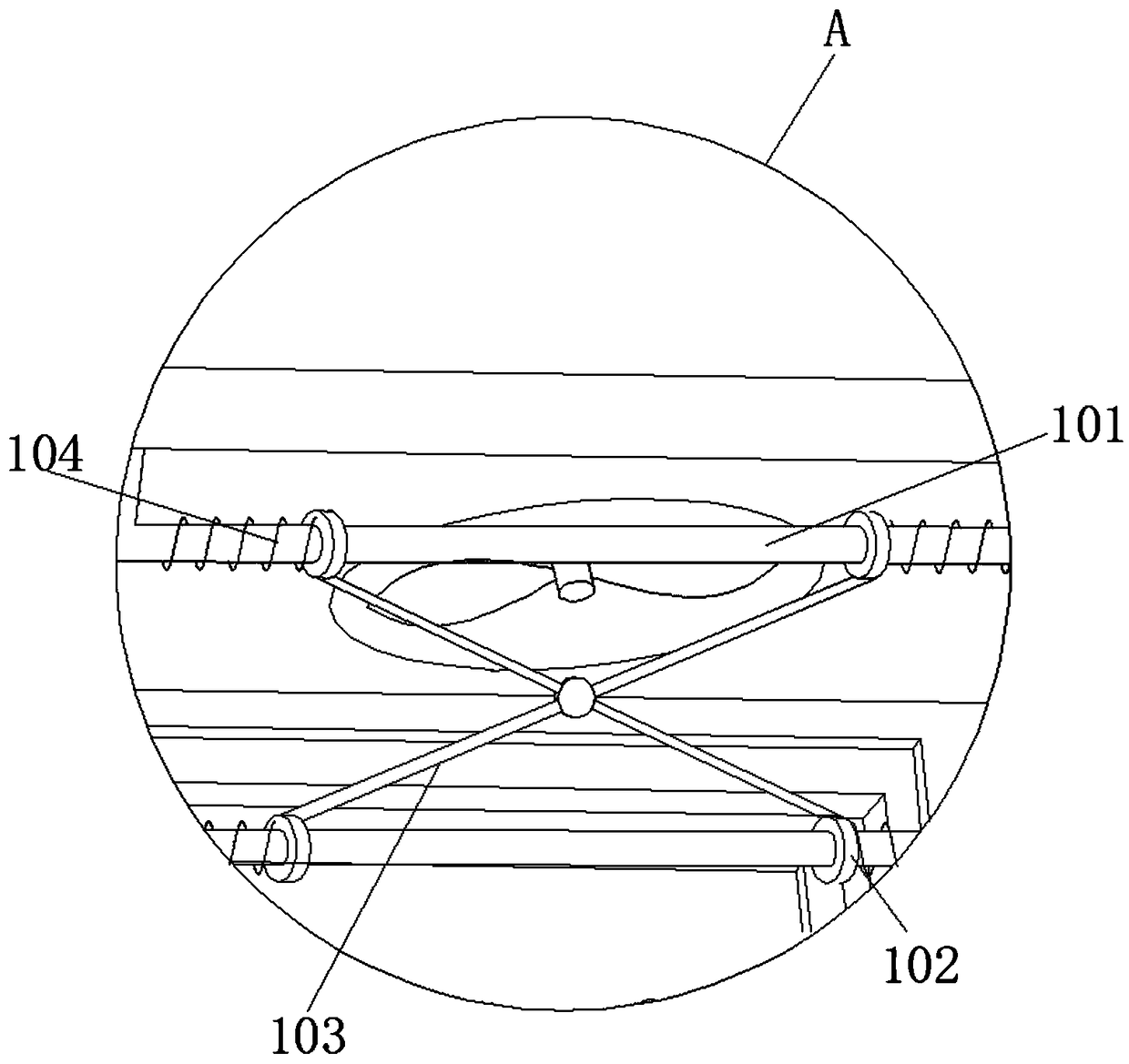

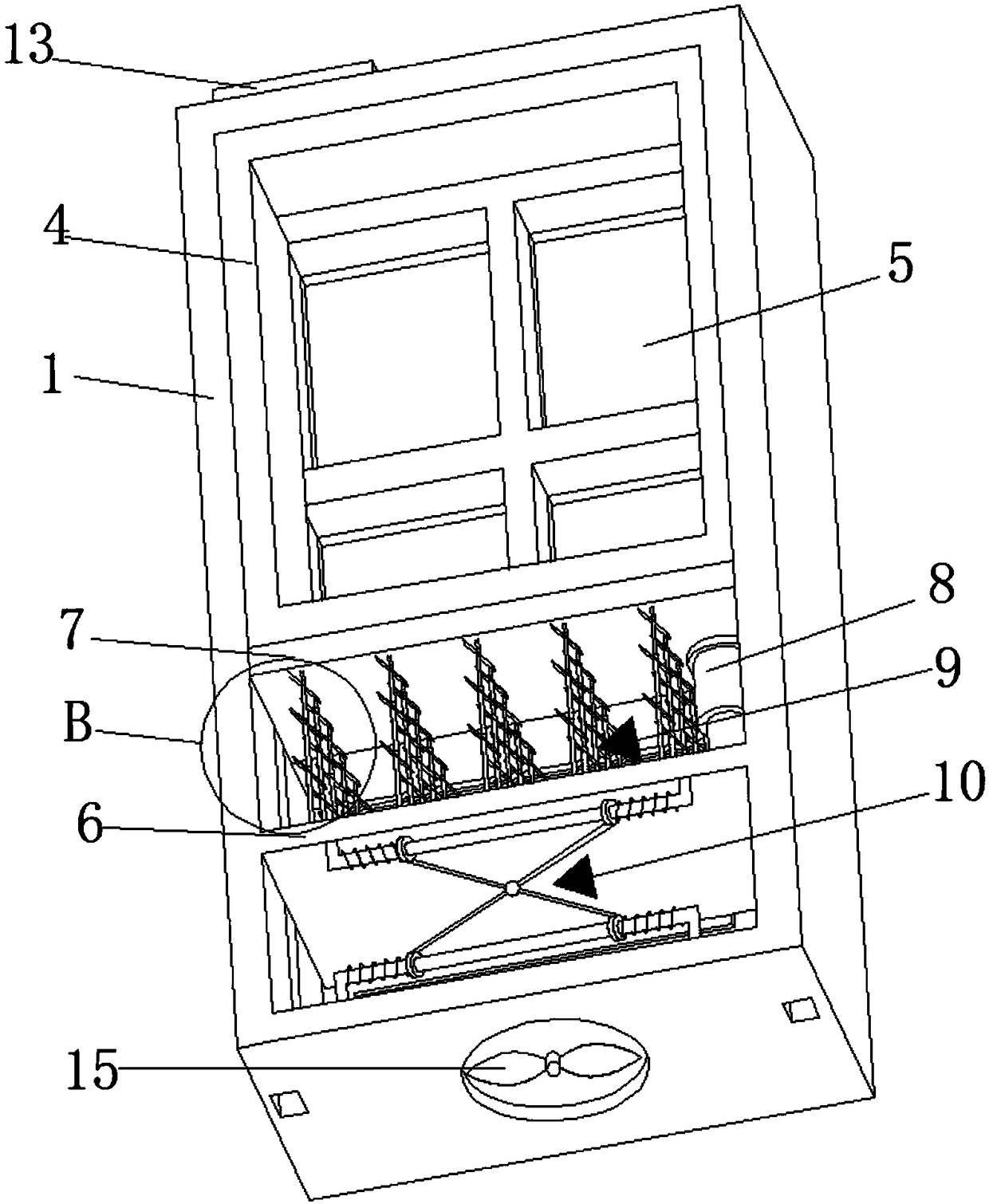

[0028] refer to Figure 1-6 , a heat dissipation device for an electric vehicle battery, comprising a box body 1, a serpentine groove 2 is provided on the inner wall of the bottom of the box body 1, a cooling pipe 3 is arranged in the serpentine groove 2, and the cross section of the cooling pipe 3 is a square structure , and the cooling pipe 3 offsets the fixing seat 4, increases the contact area with the fixing seat 4, and improves the water-cooling heat dissipation efficiency. A water collection tank 13 is connected to the longitudinal outer wall of the box body 1 near the fixed seat 4, and the water collection tank 13 is provided with a water pump 14. The water inlet and outlet ends of the cooling pipe 3 are respectively connected to the output end of the water pump 14 and the water collection tank 13. , the lateral inner wall of the box body 1 is sequentially connected with a heat dissipation plate 6 and a heat conduction plate 7 along the horizontal direction, the heat c...

Embodiment 2

[0030] refer to Figure 1-6 , a heat sink for an electric vehicle battery, which is basically the same as in Embodiment 1, except that the bottom wall of the serpentine groove 2, the outer wall of the fixing seat 4 and the heat dissipation plate 6 are provided with evenly distributed heat dissipation holes 11, and All are connected with dustproof cover 12 in the radiating hole 11, casing 1 is provided with opening away from the side outer wall of water collecting tank 13, and the inwall of opening is connected with negative pressure blower fan 15 by support, realizes the function that improves air circulation speed, improves Air cooling efficiency.

Embodiment 3

[0032] refer to Figure 1-6 , an electric vehicle battery cooling device, which is basically the same as Embodiment 2, the difference is that the outer side wall of the box body 1 away from the water collection tank 13 is provided with an opening, and the inner wall of the opening is connected with a negative pressure fan 15 through a bracket, The heat dissipation assembly 9 includes a heat conduction sleeve 91 and a heat sink 92. Three heat conduction sleeves 91 are provided, and the heat conduction sleeves 91 are sequentially socketed, and the heat sink 92 is fixedly connected to the telescopic end of the heat conduction sleeve 91. The heat sink 92 is connected to the vertical The angle between the straight faces is 45-60 degrees, and the heat dissipation efficiency of air cooling is further improved through the cooling fins 92 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com