Dielectric barrier spark pre-ionization discharge electrode

A dielectric barrier and discharge electrode technology, which is applied in the direction of circuits, electrical components, laser components, etc., can solve the problem of destroying the uniformity of the electric field on the surface of the electrode, and achieve the reduction of metal dust pollutants, increase of life, and reduction of ablation degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

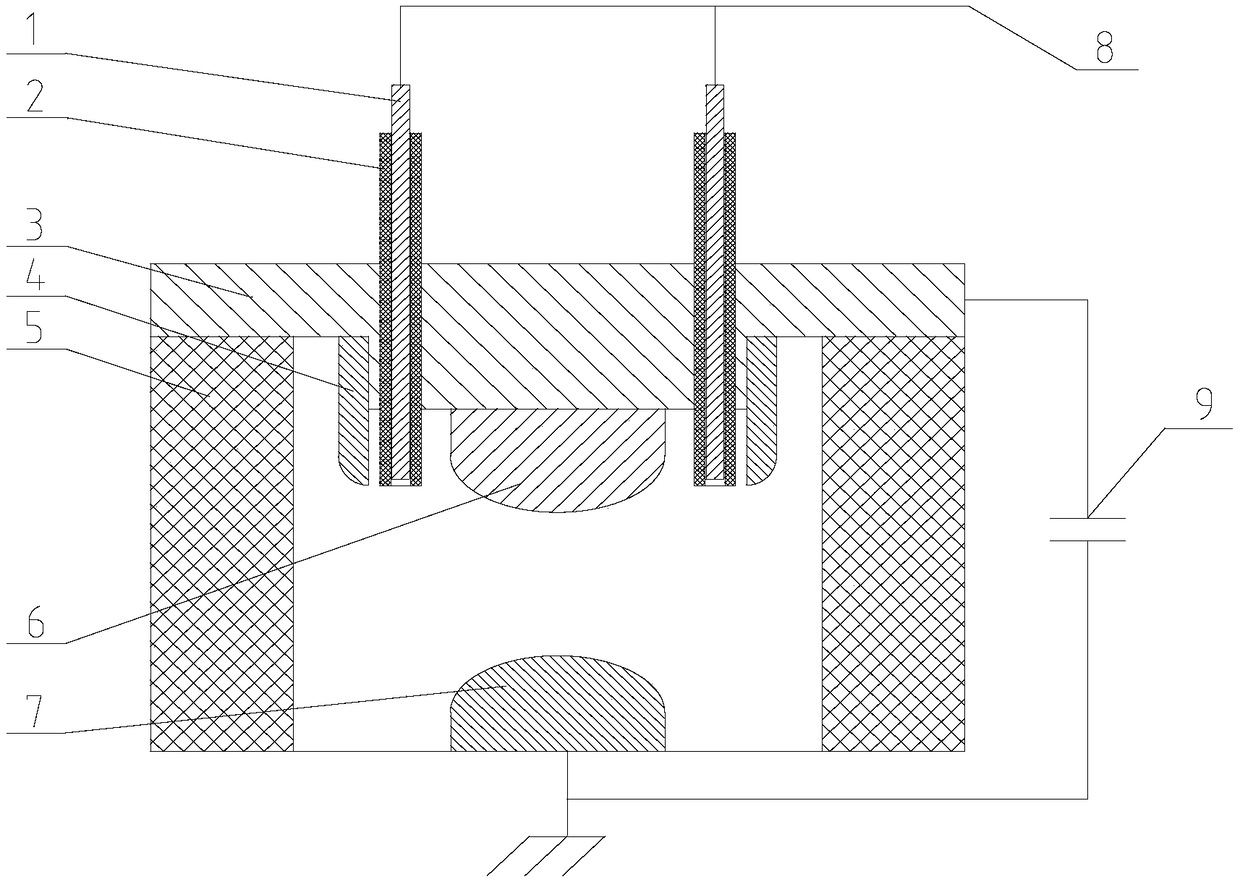

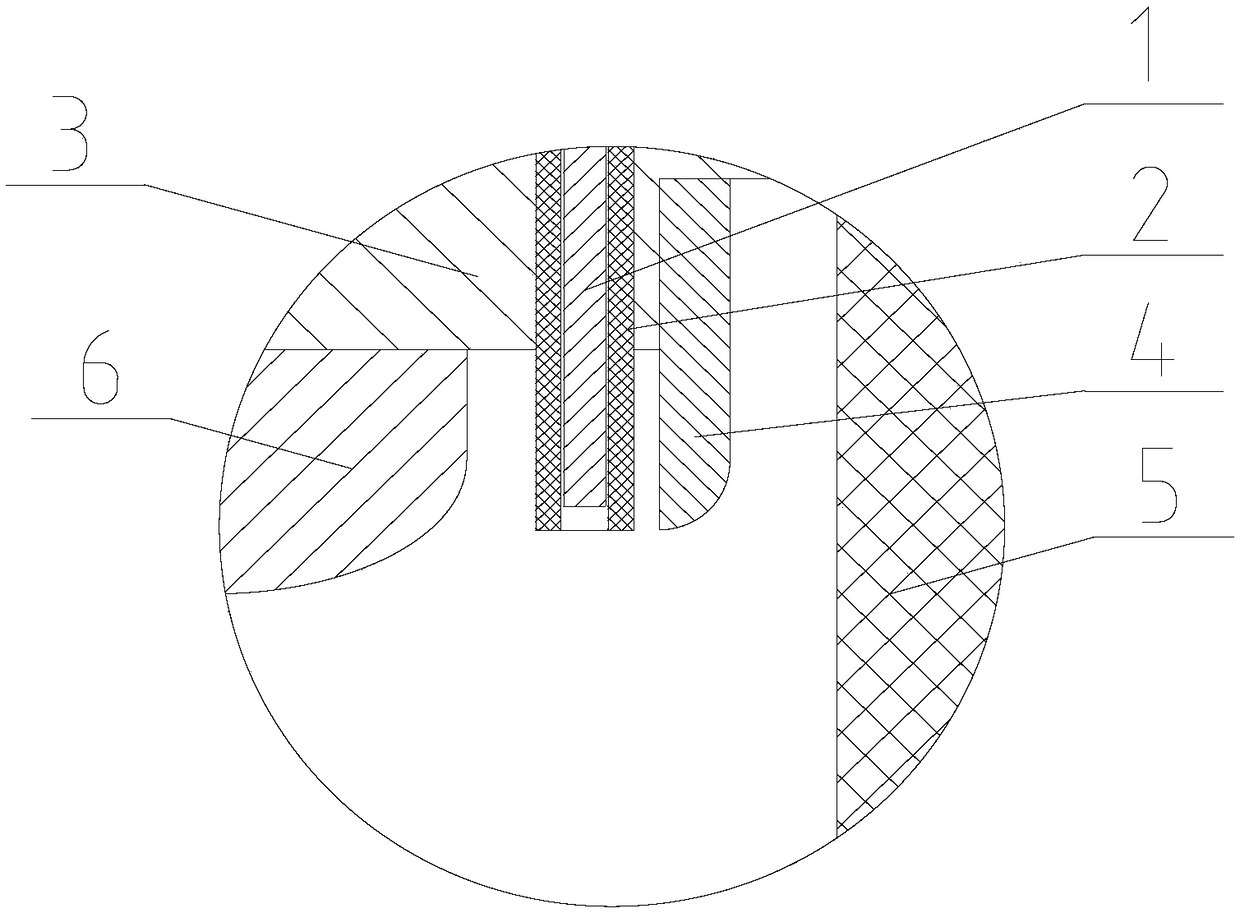

[0036] A dielectric barrier spark pre-ionization discharge electrode, including a discharge anode 7, a discharge cathode 6, an insulating frame 5 and a cathode cover 3, the discharge cathode is located on the cathode cover 3, and the cathode cover outside the discharge cathode is installed There are pre-ionization bar 4 and insulating medium tube 2, spark needle 1 is installed in said insulating medium tube 2, and the tip of spark needle 1 does not touch the bottom of insulating medium tube 2.

[0037] The distance between the tip of the spark needle 1 and the bottom of the insulating medium tube 2 is 0.9mm.

[0038] The discharge cathode 6 is installed in the middle of the cathode cover plate 3, and the side of the discharge cathode 6 opposite to the discharge anode 7 is an arc-shaped protrusion.

[0039] The insulating medium tube 2 is parallel to the pre-ionization strip 4 , and the insulating medium tube 2 and the pre-ionization strip 4 are installed on both sides of the c...

Embodiment 2

[0045] A dielectric barrier spark pre-ionization discharge electrode, comprising a discharge anode 7, a discharge cathode 6, an insulating frame 5, a cathode cover plate 3, a pre-ionization strip 4 and an insulating dielectric tube 2 are installed on the cathode cover plate 3, and the insulating A spark needle 1 is installed in the medium pipe 2, and the tip of the spark needle 1 does not touch the bottom of the insulating medium pipe 2.

[0046] The distance between the tip of the spark needle 1 and the bottom of the insulating medium tube 2 is 1.5mm.

[0047] The discharge cathode 6 is installed in the middle of the cathode cover plate 3, and the side of the discharge cathode 6 opposite to the discharge anode 7 is an arc-shaped protrusion.

[0048] The insulating medium tube 2 is parallel to the pre-ionization strip 4 , and the insulating medium tube 2 and the pre-ionization strip 4 are installed on both sides of the cathode cover plate 3 in parallel. The pre-ionization bar...

Embodiment 3

[0054] A dielectric barrier spark pre-ionization discharge electrode, comprising a discharge anode 7, a discharge cathode 6, an insulating frame 5, a cathode cover plate 3, a pre-ionization strip 4 and an insulating dielectric tube 2 are installed on the cathode cover plate 3, and the insulating A spark needle 1 is installed in the medium pipe 2, and the tip of the spark needle 1 does not touch the bottom of the insulating medium pipe 2.

[0055] The distance between the tip of the spark needle 1 and the bottom of the insulating medium tube 2 is 3.0mm.

[0056] The discharge cathode 6 is installed in the middle of the cathode cover plate 3 , and the discharge cathode 6 has the same shape as the discharge anode 7 .

[0057] The insulating medium tube 2 and the pre-ionization strip 4 are installed side by side on the outside of the cathode cover plate 3 , there are two insulating medium tubes 2 , and the pre-ionization strip 4 is located in the middle of the two insulating mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com