Automatic elimination mechanism and powder filling machine thereof

A technology of rejecting mechanism and filling machine, applied in the direction of automatic packaging control, solid material, packaging, etc., can solve the problems of linear deformation of screw, inability to precisely control filling process, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

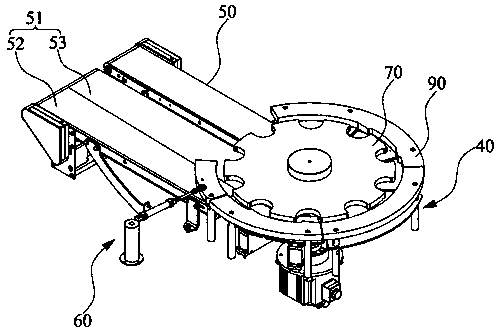

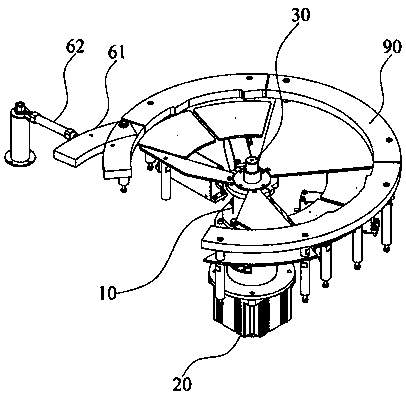

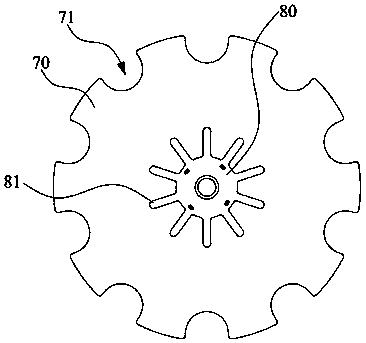

[0024] Please also refer to Figure 1 to Figure 3 , figure 1 It is a three-dimensional view of the automatic rejecting mechanism of the embodiment of the present invention; figure 2 It is an internal schematic diagram of the automatic rejecting mechanism of the embodiment of the present invention; image 3 It is a schematic diagram of the rotary tray of the embodiment of the present invention. As shown in the figure, an automatic rejecting mechanism includes a fuselage workbench; a base bushing 10 installed on the fuselage workbench; a servo motor 20 arranged at the lower end of the base bushing 10; The power spindle 30 of the base bushing 10 is set; the multiple fe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap