Oil-water separation device with sterilization function

An oil-water separation device, oil-water separation technology, applied in the direction of grease/oily substance/floating matter removal device, multi-stage water treatment, light water/sewage treatment, etc., can solve the problem of affecting urban appearance and living environment, and affecting people's health and other problems, to achieve the effect of preventing the deterioration of bacteria and improving the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

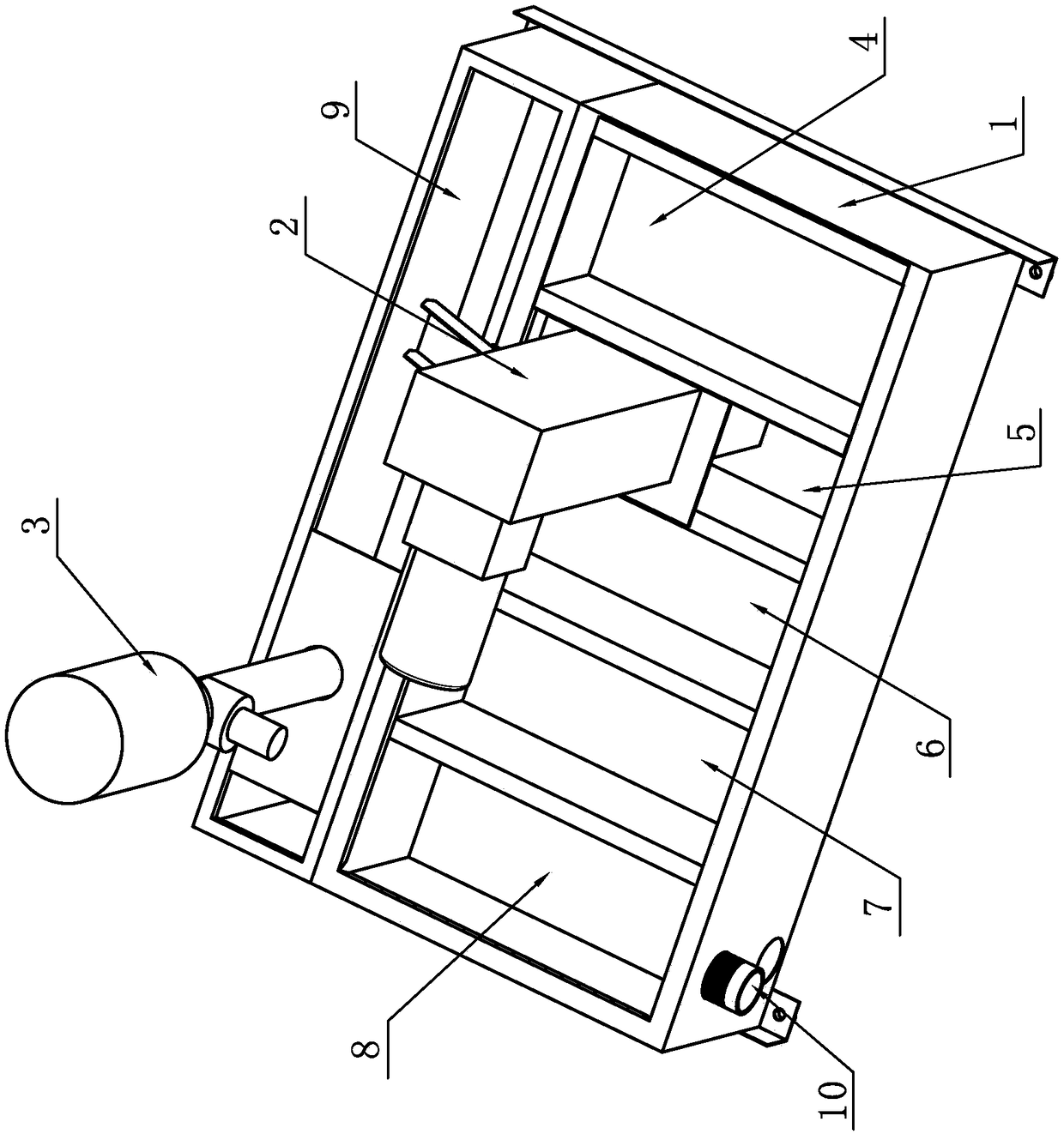

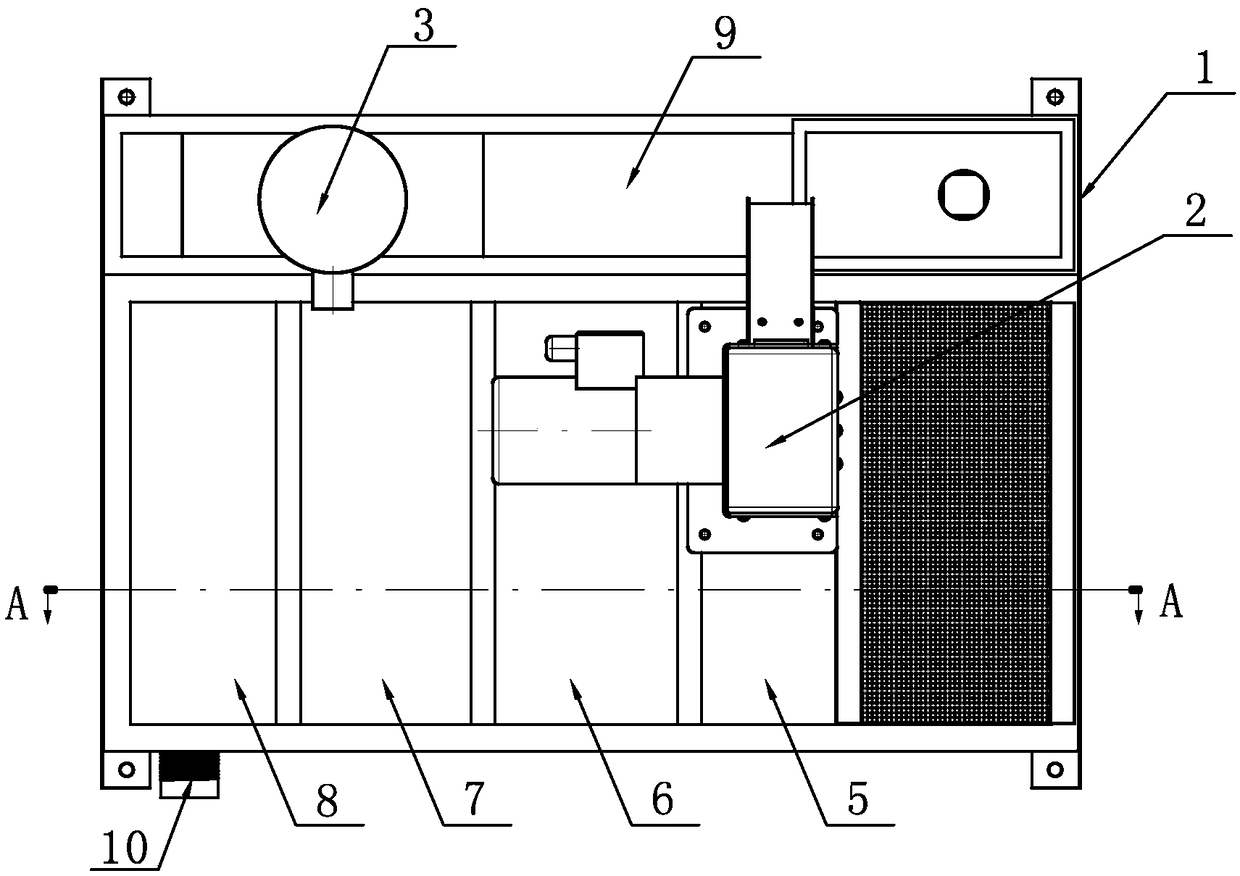

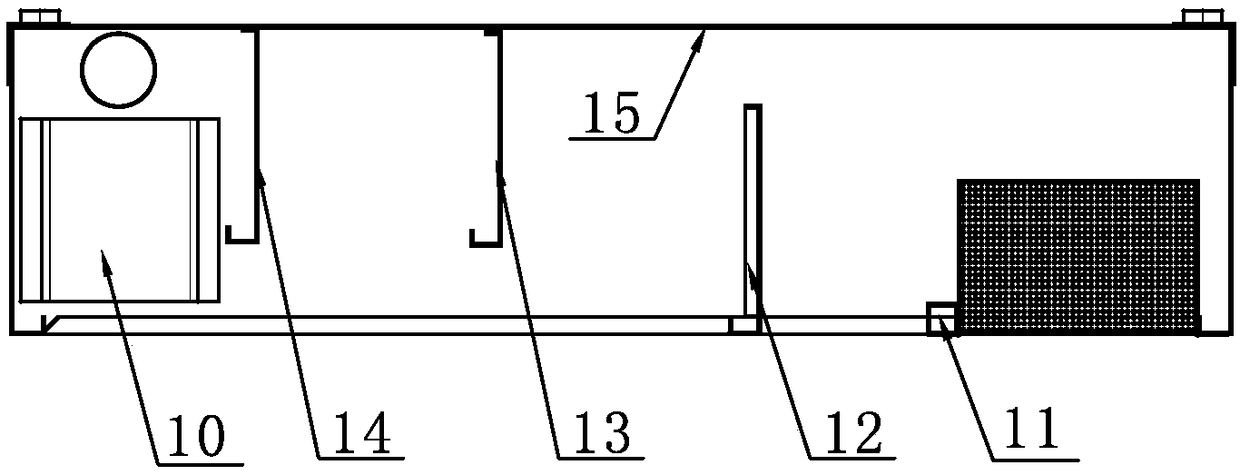

[0022] Embodiment 1: a kind of oil-water separation device with sterilization function, such as Figure 1-Figure 5 As shown, it includes a step-by-step oil-water separation box 1, an oil holder 2, and an oil pump 3. The step-by-step oil-water separation box 1 includes a liquid mixing bin 4, a collection oil bin 5, a first oil filter bin 6, and a transition oil filter bin 7 , water outlet bin 8, oil storage bin 9 and sterilizing lamp, mixed liquid bin 4, oil collection bin 5, first oil filter bin 6, transition oil filter bin 7 and water outlet bin 8 are distributed in sequence, and oil storage bin 9 is arranged in the oil collection bin 5, the oil trap 2 is installed in the oil collection bin 5, and the oil well pump 3 is installed in the oil storage bin 9. The oil trap 2 includes a frame 21, an oil trap motor 22, a driving pulley 23, and a Driving pulley 24, synchronous belt 25, oil-containing plate 26 and oil guide groove 27, frame 21, oil-containing motor 22, driving pulley ...

Embodiment 2

[0023] Embodiment 2: The difference from Embodiment 1 is that the location of the germicidal lamp is different. In this example, the germicidal lamp is arranged on the top side of the oil storage bin 9 .

Embodiment 3

[0024] Embodiment 3: The difference from Embodiment 1 lies in that the installation position of the germicidal lamp is different, and the germicidal lamp is arranged at the oil outlet of the oil holder 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com