Special-structured PDC drill bit

A drill bit and special-shaped technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of rock breakage in the formation, fatigue of downhole drilling tools, and decrease in ROP, so as to reduce the density of teeth and increase the pressure of a single tooth. , the effect of low layout density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

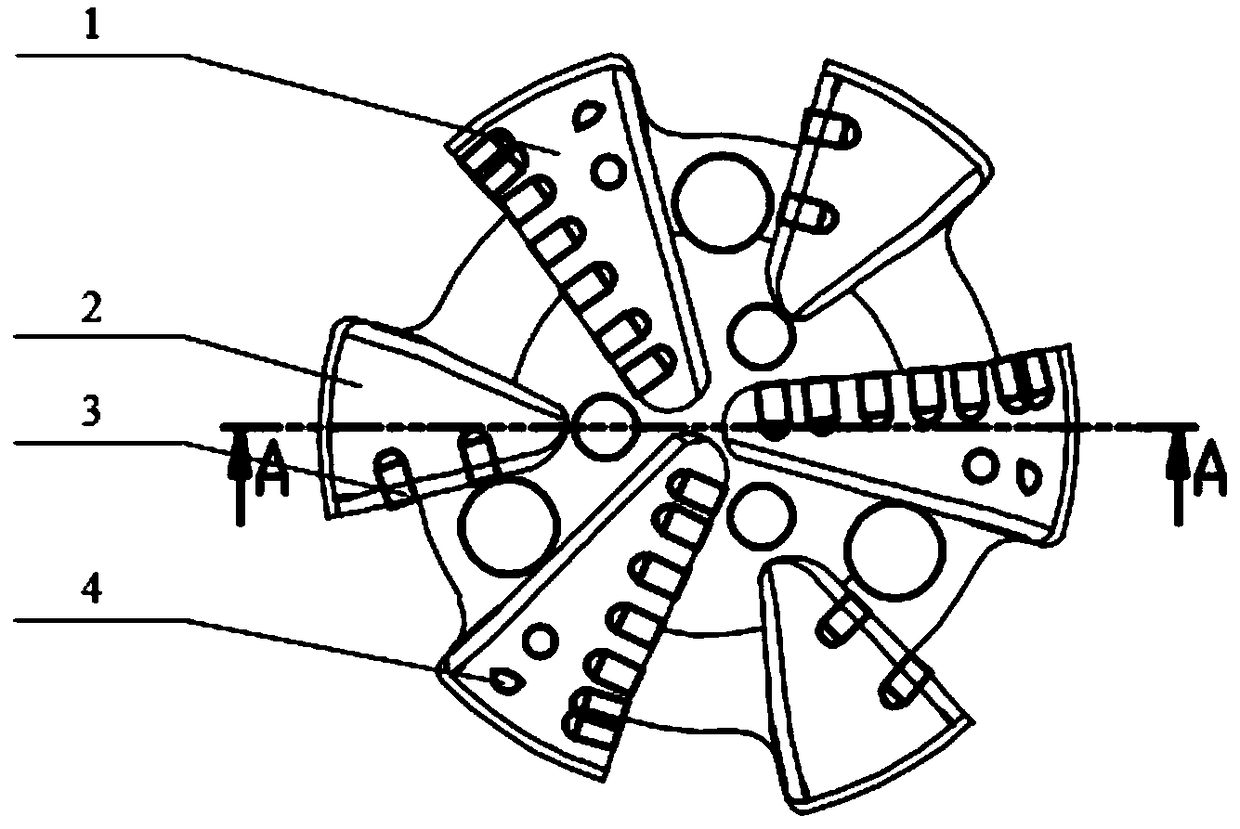

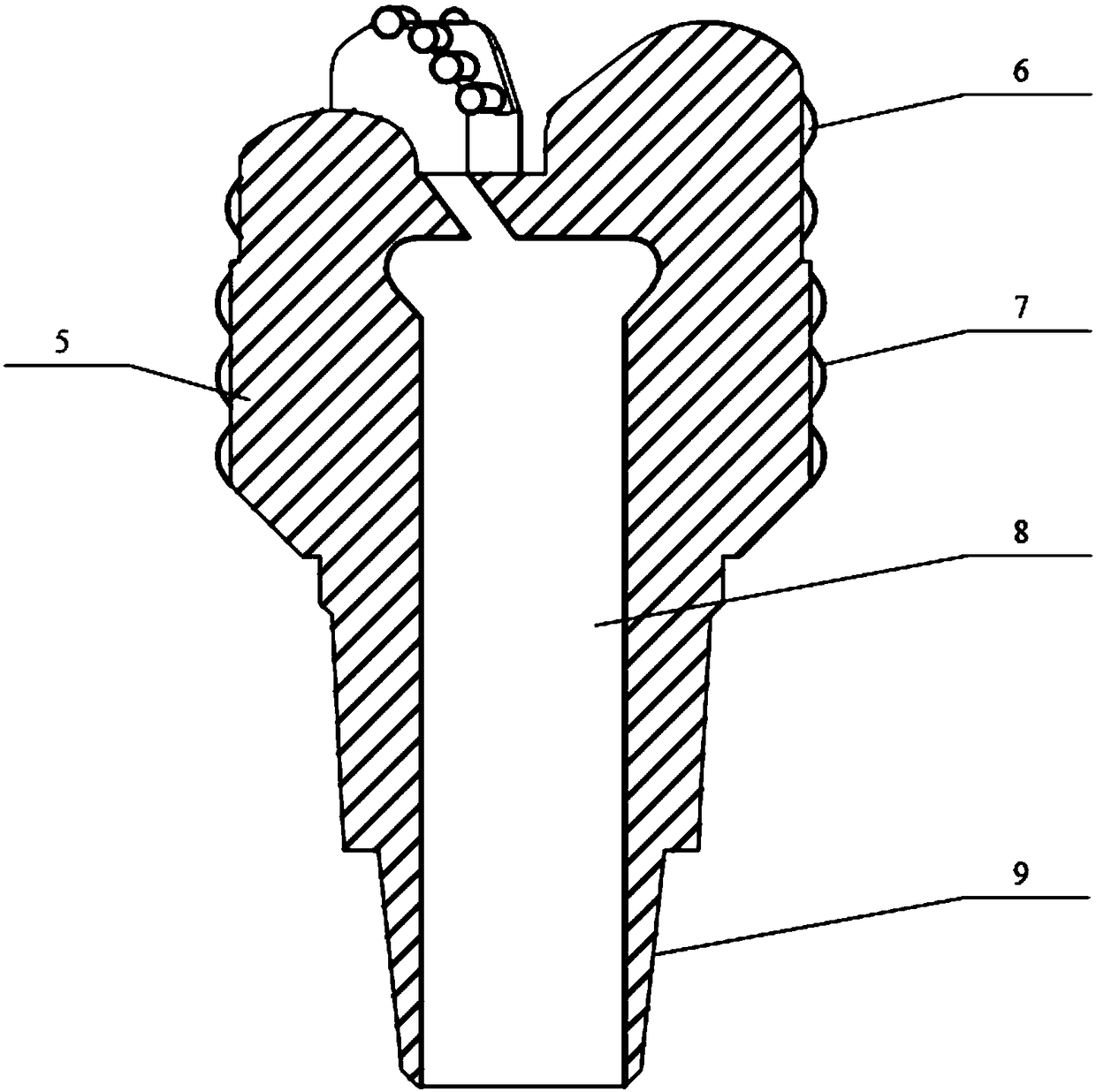

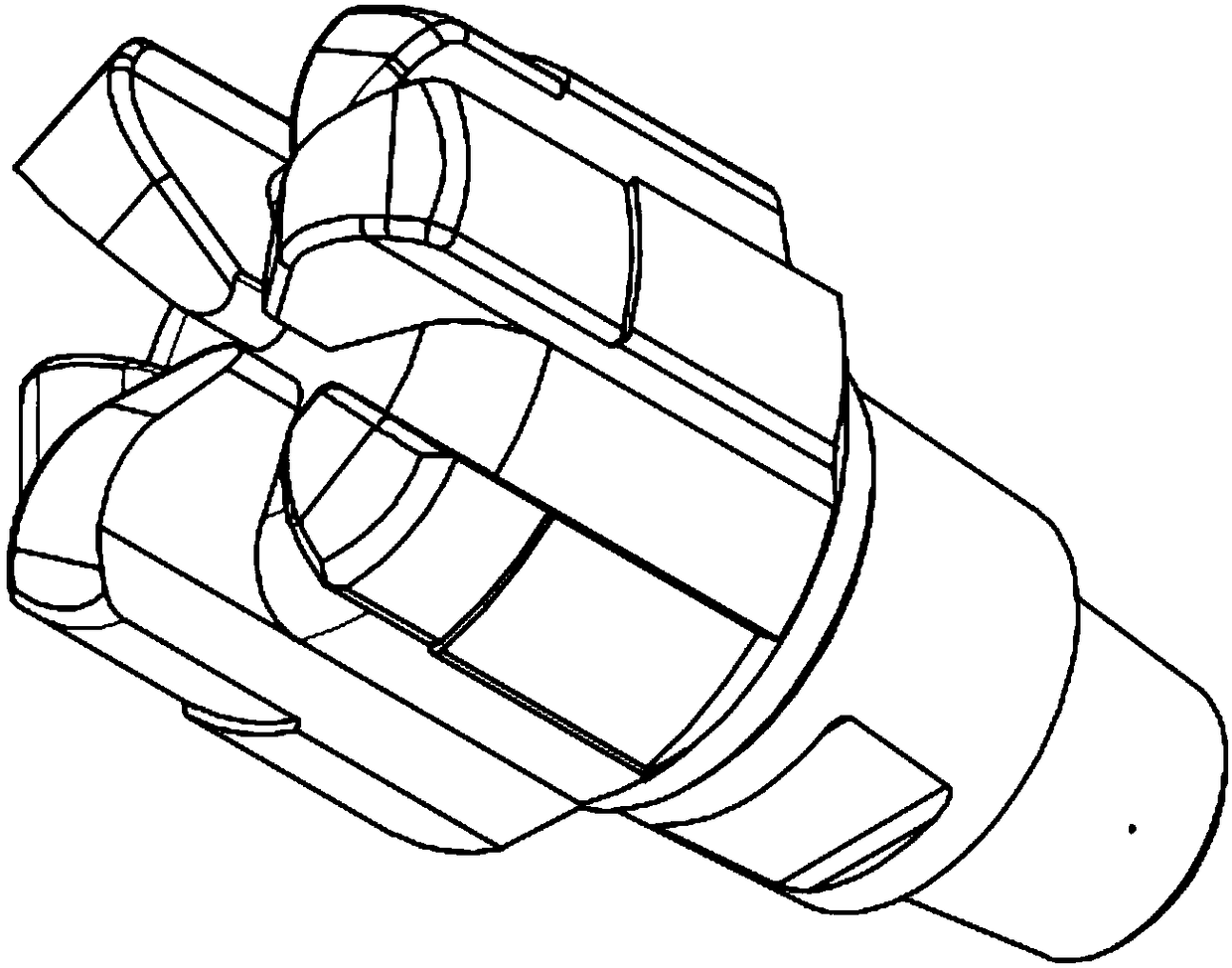

[0013] The main structure of the special-shaped structure PDC drill bit described in this embodiment includes cutting wings 1, stabilizing wings 2, PDC cutting teeth 3, spherical stabilizing teeth 4, drill neck protection 5, PDC lateral cutting teeth 6, spherical anti-wear teeth 7, fluid The channel 8 and the connecting thread 9, the cutting wing 1 and the stabilizing wing 2 are evenly distributed along the circumferential direction, and the exposed part of the bit body of the stabilizing wing 2 is shorter than the cutting wing 1, so that only the cutting wing contacts the formation when the special-shaped structure PDC bit is drilled and break rocks; the crown of cutting wing 1 is sintered, mounted or bonded with PDC cutting teeth 3 and spherical stabilizing teeth 4, PDC cutting teeth 3 are used to cut formation rocks, and spherical stabilizing teeth 4 are used to prevent brittle PDC during drilling The vibration / whirling of the cutting teeth due to uneven cutting can avoid th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com